Release film for heat-conducting silica gel sheet and preparation method thereof

A heat-conducting silica gel sheet and release film technology, which is applied in chemical instruments and methods, adhesives, heat exchange materials, etc., can solve the problems of the decline in the mechanical properties of the silicone oil layer, the shedding of the silicone oil layer, and the inevitable, etc., to improve adhesion, The effect of preventing falling off and improving the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

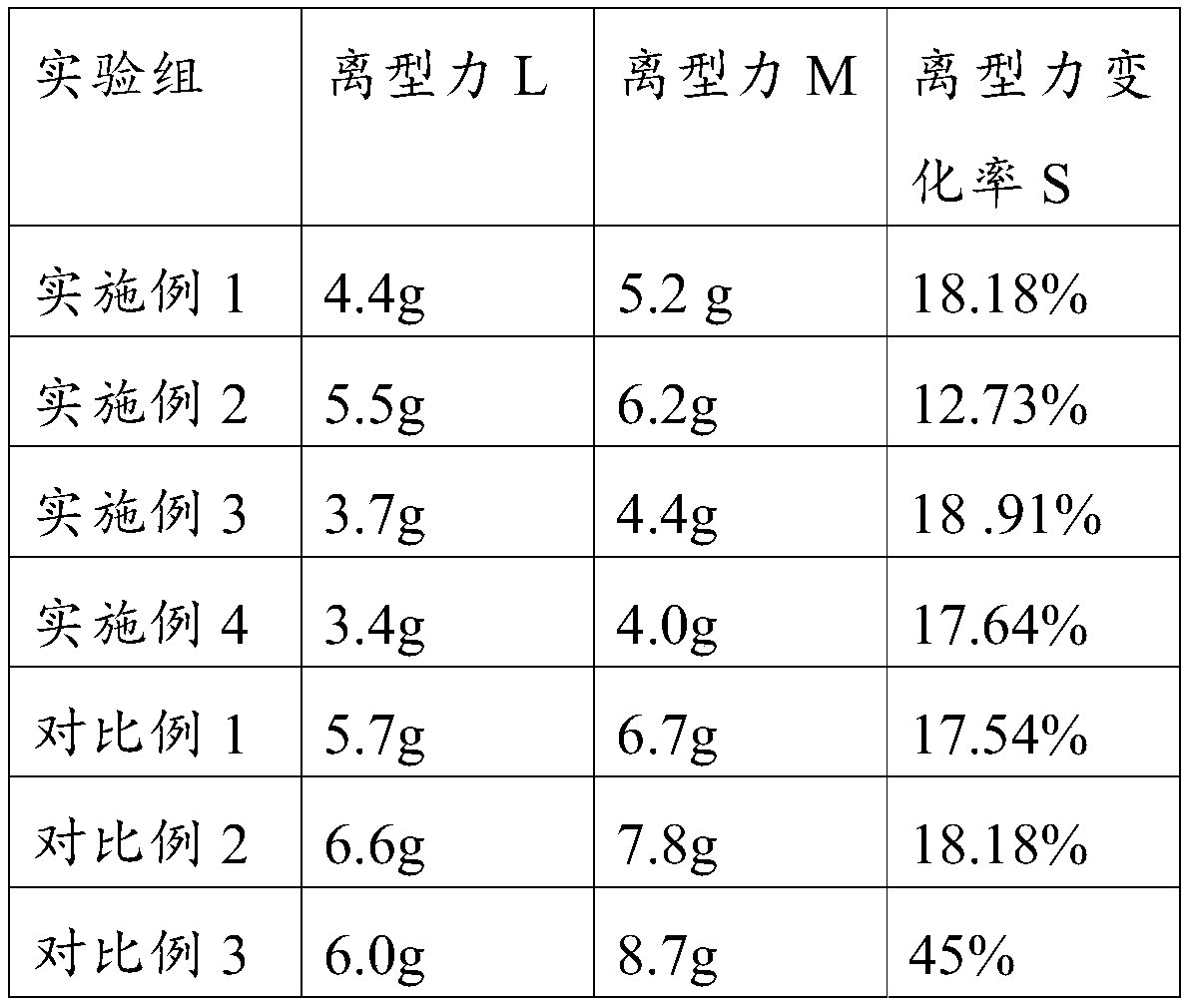

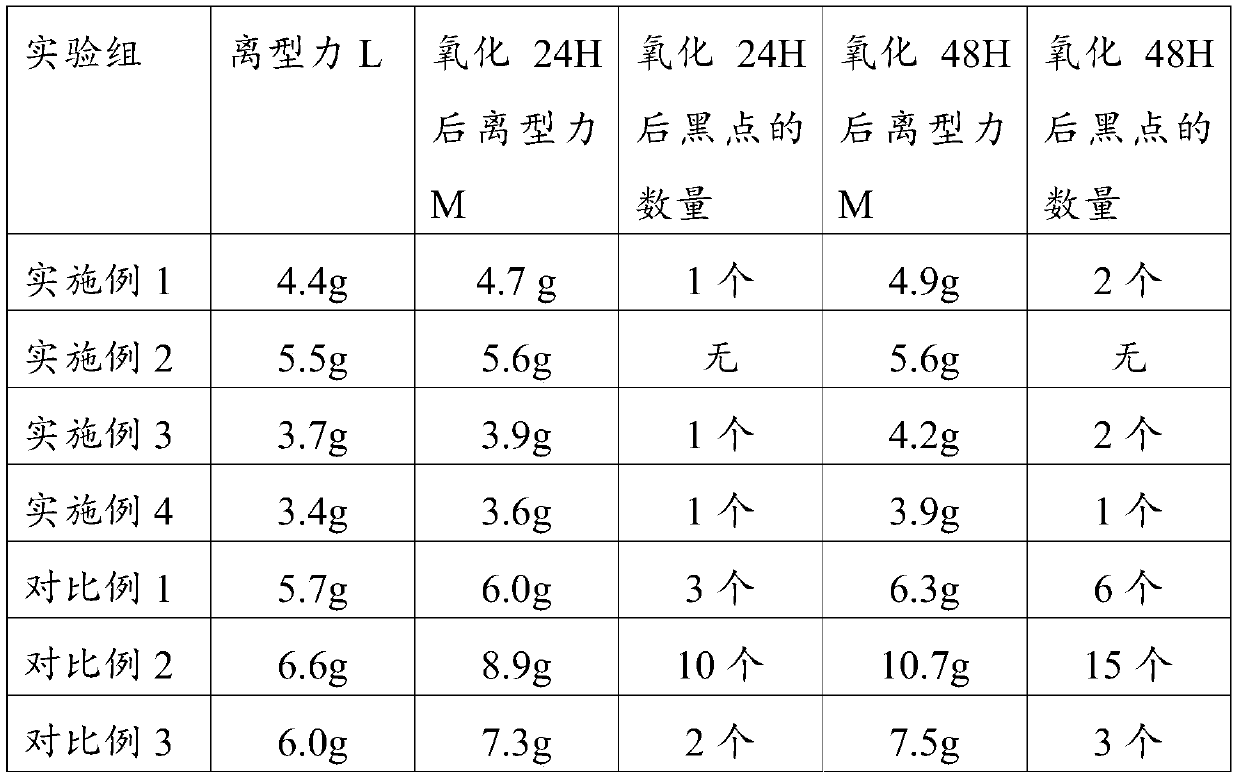

Examples

Embodiment 1

[0024] The preparation method of the release film for the heat-conducting silica gel sheet of the present embodiment, the steps include:

[0025] (1) Add 15 parts of phenyltrichlorosilane, 11 parts of toluene, 11 parts of ethyl acetate, 11 parts of isopropanol, 44 parts of cyclohexane, and 11 parts of acetone into the container and stir evenly. The speed is 1500r / min;

[0026] (2) Add 2 parts of vinyltriethoxysilane, 2 parts of platinum carbon catalyst (platinum content is 3wt%), 1 part of adhesion promoting resin and 4 parts of dialkyldithiocarbamate in the container, Stir well;

[0027] (3) Add 5 parts of modified alkylphenol formaldehyde resin into the container, stir evenly, add 1.5 parts of isomeric tridecanol polyoxyethylene ether and heat the temperature to 40 degrees to obtain a release liquid;

[0028] (4) The surface of the PET substrate is treated with an electric arc to form a rough layer with a thickness of 4um. The release liquid is coated on the surface of the...

Embodiment 2

[0030] The preparation method of the release film for the heat-conducting silica gel sheet of the present embodiment, the steps include:

[0031] (1) Add 10 parts of Dow Corning silicone oil, 9 parts of toluene, 18 parts of ethyl acetate, 10 parts of isopropanol, 24 parts of cyclohexane, and 20 parts of acetone into the container and stir evenly at a stirring speed of 1200r / min;

[0032] (2) Add 4 parts of vinyltriethoxysilane, 1 part of chloroplatinic acid catalyst (platinum content is 3wt%), 1.5 parts of adhesion promoting resin and 8 parts of dialkyldithiocarbamate into the container , stir evenly;

[0033] (3) Add 10 parts of modified alkylphenol formaldehyde resin into the container, stir evenly, add 3 parts of isomeric tridecyl alcohol polyoxyethylene ether and heat the temperature to 60 degrees to obtain a release liquid;

[0034] (4) The surface of the PET base material is treated with an electric arc to form a rough layer with a thickness of 3um. The release liquid...

Embodiment 3

[0036] The preparation method of the release film for the heat-conducting silica gel sheet of the present embodiment, the steps include:

[0037] (1) Add 15 parts of phenyltrichlorosilane, 15 parts of toluene, 15 parts of ethyl acetate, 30 parts of isopropanol, 8 parts of cyclohexane, and 20 parts of acetone into the container and stir evenly. The speed is 1500r / min;

[0038] (2) Add 2 parts of vinyltriethoxysilane, 2 parts of platinum carbon catalyst (platinum content is 3wt%), 1 part of adhesion promoting resin and 4 parts of dialkyldithiocarbamate in the container, Stir well;

[0039] (3) Add 5 parts of modified alkylphenol formaldehyde resin into the container, stir evenly, add 1.5 parts of isomeric tridecanol polyoxyethylene ether and heat the temperature to 40 degrees to obtain a release liquid;

[0040] (4) The surface of the PET substrate is treated with an electric arc to form a rough layer with a thickness of 4um. The release liquid is coated on the surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com