Crosslinkable durable scratch-resistant organic silicon master batch and preparation method thereof

A scratch-resistant and organosilicon technology, applied in the field of plastic additives, can solve the problems of unsustainable scratch-resistant performance, easy hydrolysis of active groups, and difficulty in industrialization, achieving durable and stable scratch-resistant performance and simple preparation process. Controllable, simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

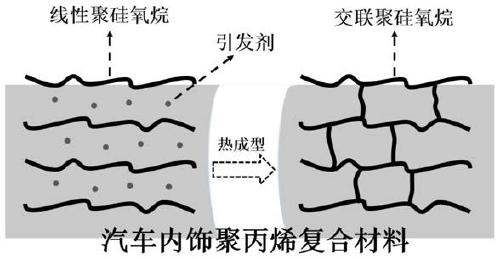

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

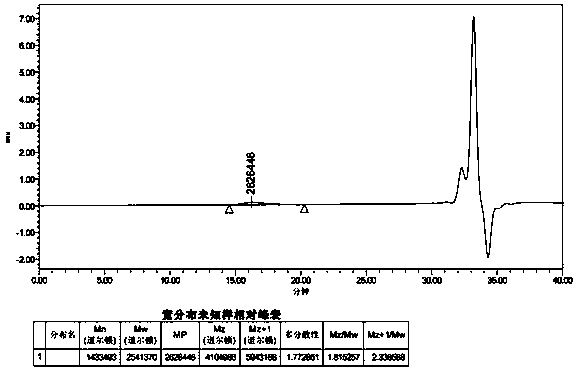

[0027] Preparation Examples and Comparative Examples of Crosslinkable Durable Scratch-resistant Silicone Masterbatch

[0028] See Table 1 for the silicone masterbatch components and component mass fractions in Examples and Comparative Examples.

[0029] Table 1 Silicone masterbatch components and component mass fraction

[0030]

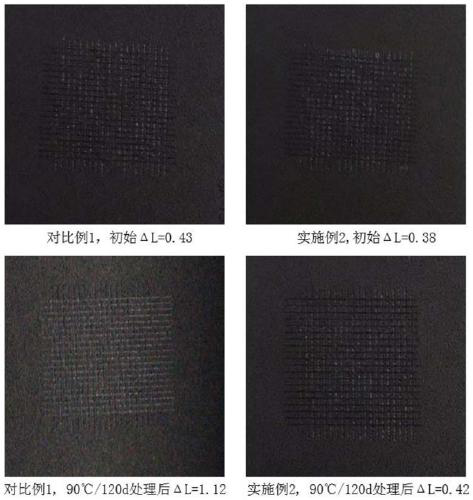

[0031] Examples 1-6 silicone masterbatches contain a peroxide initiator, and the selected vinyl polysiloxane is high molecular weight polysiloxane. Compared with the examples, the organosilicon masterbatch in comparative example 1 does not contain peroxide initiator,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com