Inoculation line formula for gray cast iron feeding and inoculation and production process

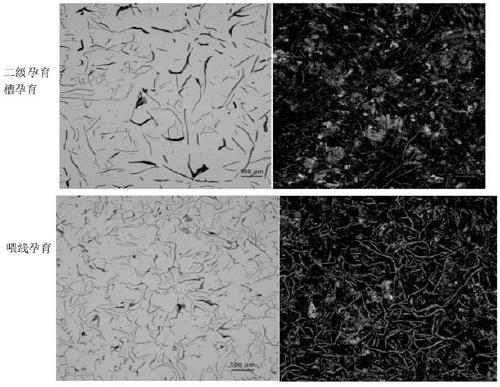

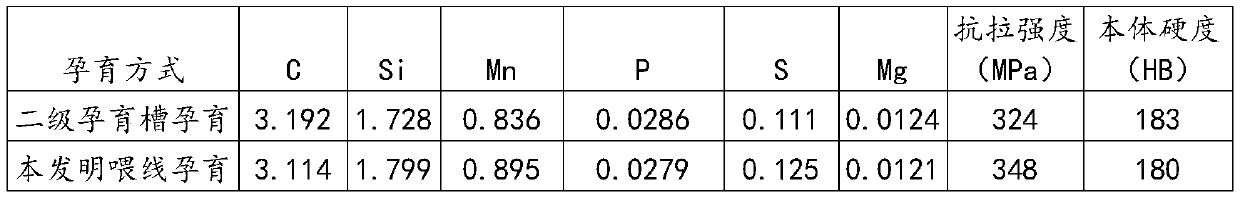

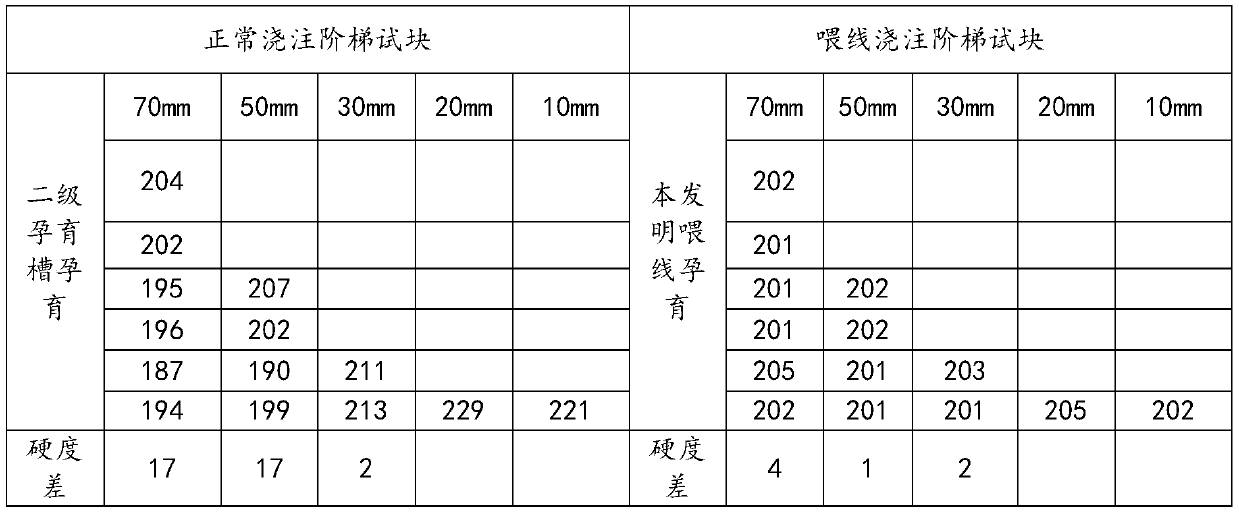

A production process and technology for gray cast iron, applied in the field of inoculation line formulation and inoculation process, can solve the problems of uneven inoculation, unstable and insufficient production of gray cast iron, and achieve uniform inoculation, small hardness drop, and prevention of inoculation recession.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better reflect the technical features and advantages of the present invention, the present invention will be described in detail through the following specific embodiments.

[0020] Using this technical solution to cast a kind of saddle product, the main chemical composition (except Fe) detected by the finished product inoculation line is magnesium 2.4%, silicon 53.4%, rare earth 1.6%, barium 2.4%, calcium 1.1%, aluminum 1.3%, The chemical composition of the inoculation line meets the requirements of the formulation process.

[0021] The specific technical process of using this inoculation line to produce saddle castings is as follows:

[0022] 1) Selection of raw materials: smelting in a 10-ton industrial frequency electric furnace, adding 6470Kg of scrap steel, 3051Kg of returned iron, and 504Kg of gray pig iron in sequence. The last addition of gray pig iron is mainly to ensure the melting of the molten iron core.

[0023] 2) Melting process: Continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com