Aviation blade tenon laser scanning measuring machine and measuring method

A technology of laser scanning and aviation blades, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low measurement efficiency, low degree of automation, mismatch between detection rhythm and production rhythm, and improve measurement repeatability and accuracy performance, reduce the number of disassembly and attitude adjustment, and meet the needs of high-efficiency and precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions.

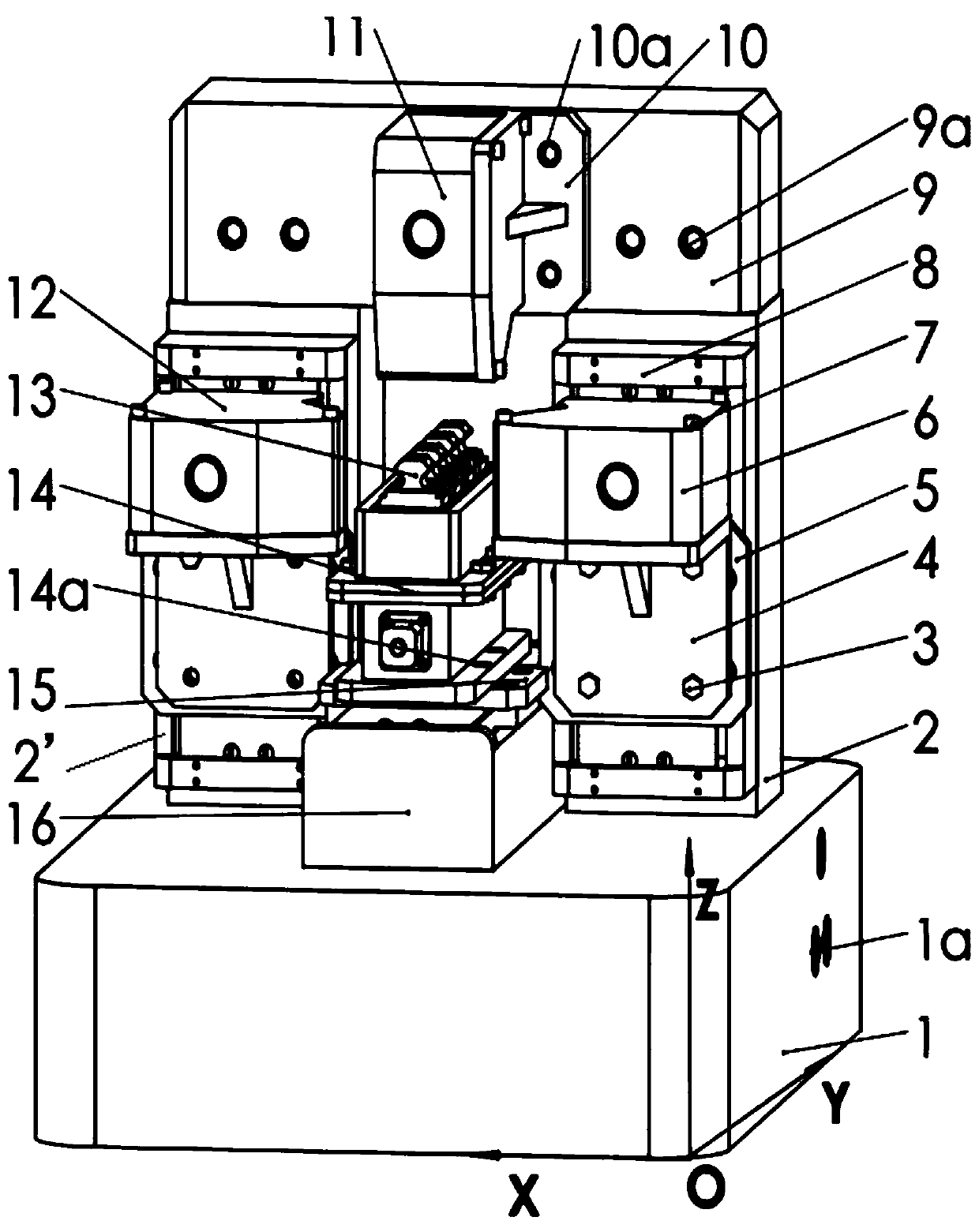

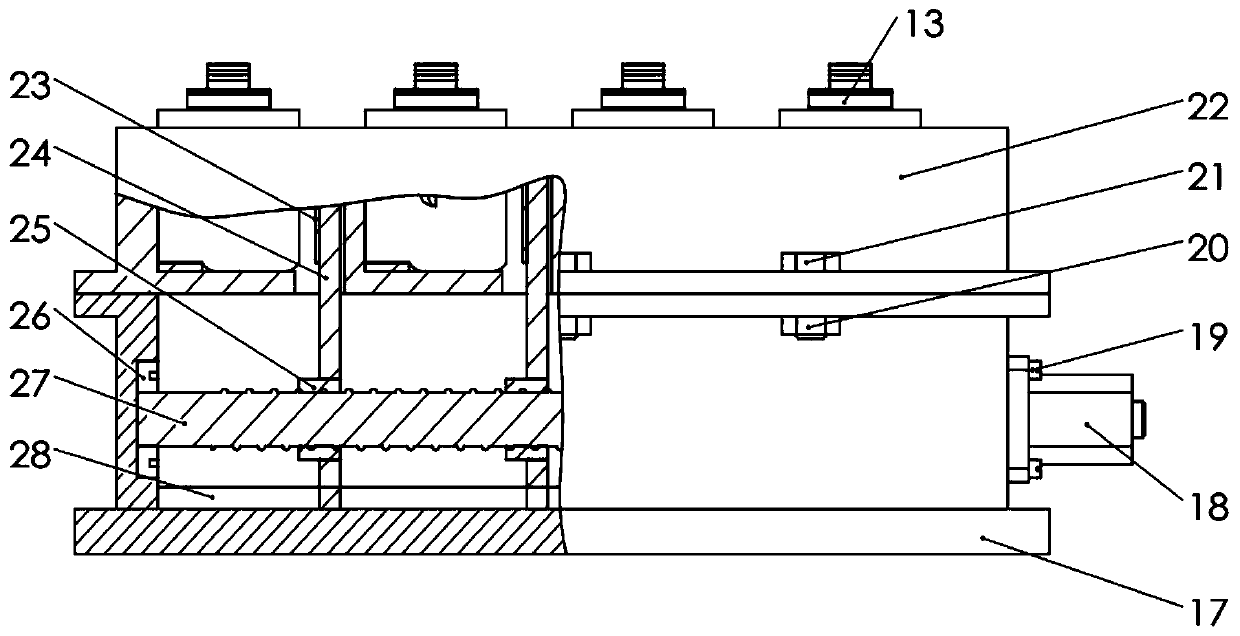

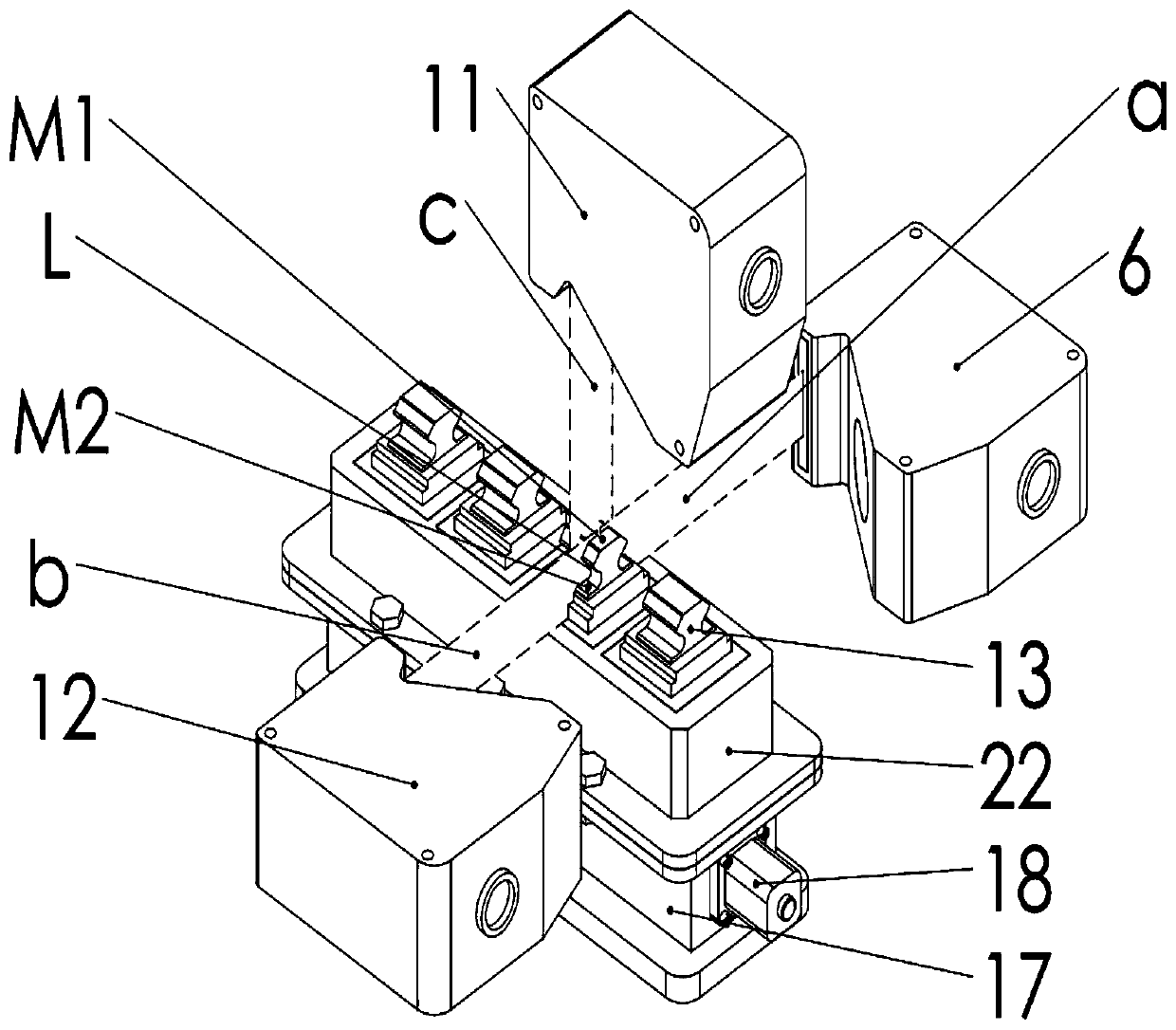

[0020] An aviation blade tenon line laser scanning measuring machine of the present invention is composed of a fixed bridge-type measuring platform, a sensor part and a tenon tooling fixture part, see the attached figure 1 , 2 . The sensor part is composed of three line laser sensor parts, and the three line laser sensors are respectively fixed to the left and right columns and beams of the fixed bridge-type measurement platform; the tenon tooling fixture part is installed on the marble measurement table between the two columns of the measurement platform.

[0021]The fixed bridge-type measuring platform is made up of marble measuring platform 1, left and right columns 2', 2 and beam 9. The side of the marble measuring platform 1 is processed with platform countersunk holes 1a, the surface is processed with gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com