Pump pipe valve system with intelligent remote monitoring, early warning and control terminal

A technology for remote monitoring and control of terminals, applied in the system field, can solve the problems of no monitoring equipment, no long-distance transmission, and no intelligent control of devices, so as to reduce losses and avoid major disasters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

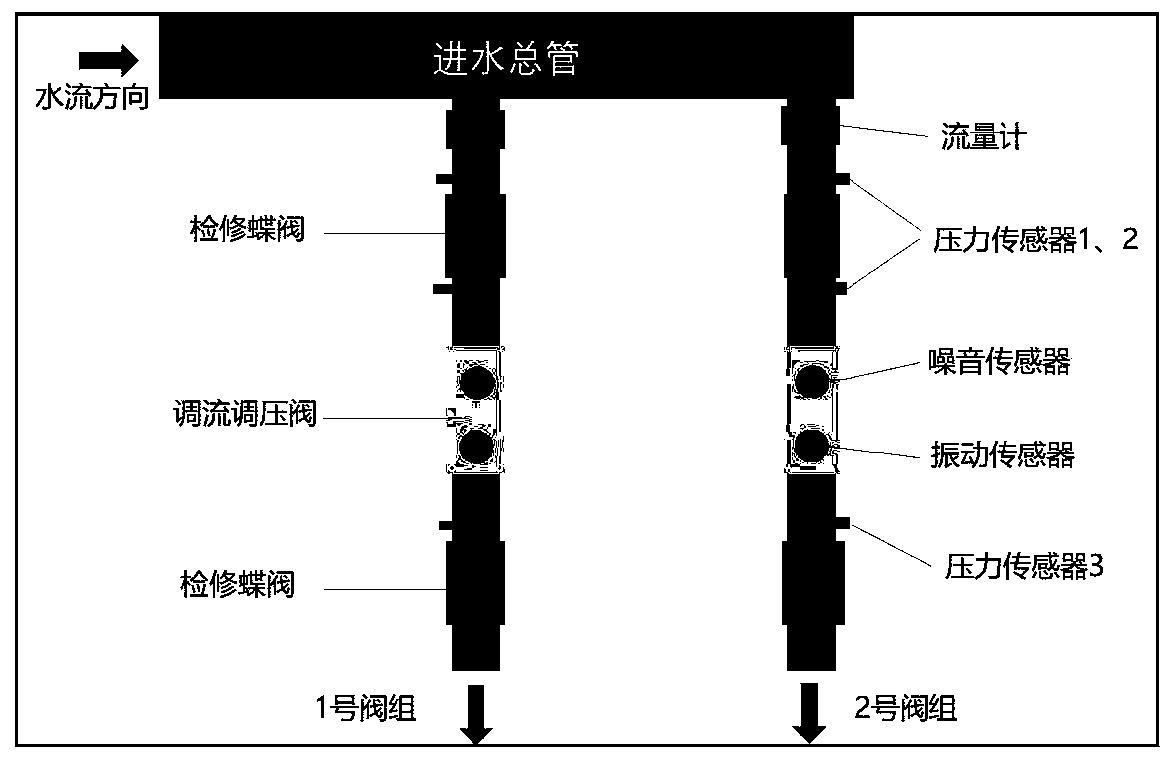

[0018] The pump pipe valve system with intelligent remote monitoring, early warning and control terminal, intelligent remote monitoring, early warning and control terminal, is composed of micro-hydraulic power generation control board and data acquisition board; data acquisition board includes processor, on-board memory chip, Isolated interface, digital input interface, digital output interface, analog input interface and several function expansion sockets, on-board memory chip, isolated interface, digital input interface, digital output interface, analog input interface, and expansion socket are separately connected to the processor The micro hydropower control board is connected with the data acquisition board through the bus.

[0019] The equipment and devices connected to the intelligent remote monitoring early warning and control terminal in each pump station and valve room collect real-time data and transmit them to the intelligent remote monitoring early warning and cont...

Embodiment 2

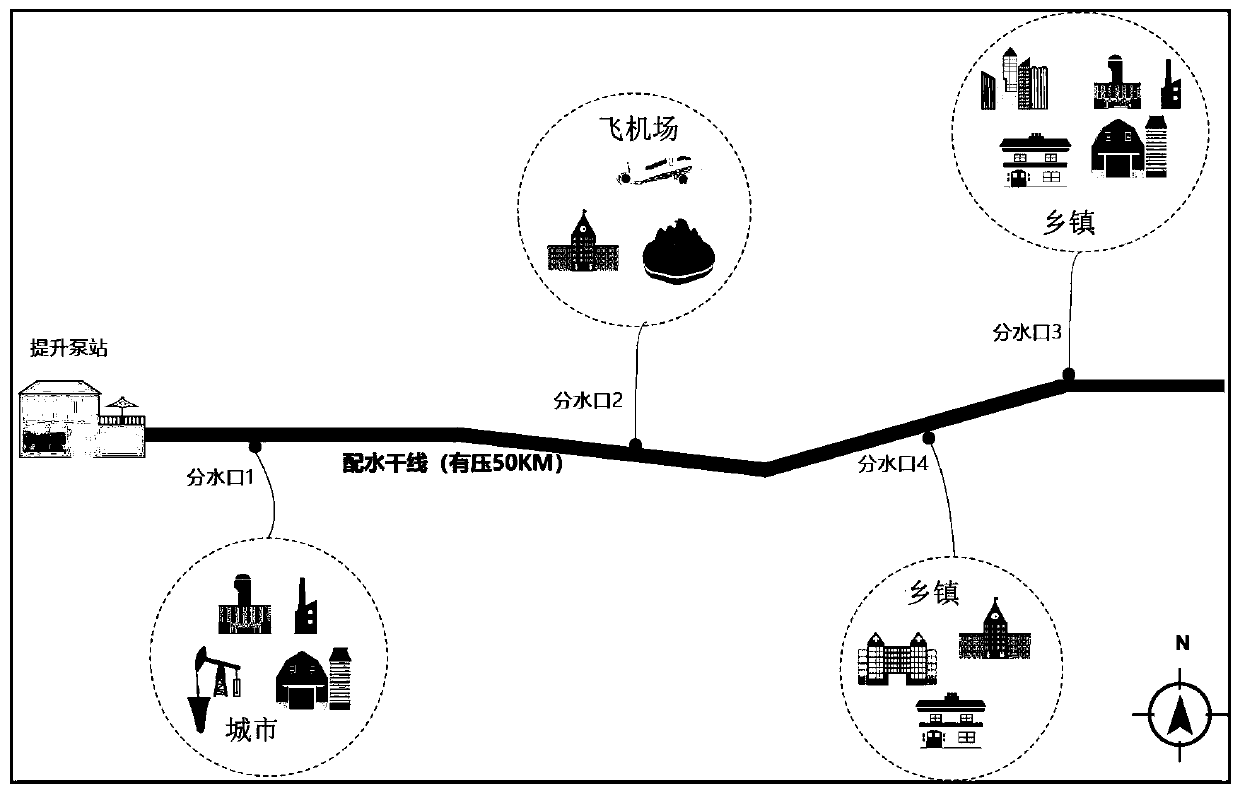

[0023] Different from Embodiment 1, Embodiment 2 is distributed control of multiple intelligent remote monitoring, early warning and control terminals. In long-distance water transmission projects, in the multi-point water outlet valve chamber of the pipeline, the safe operation of the pipeline to realize the control of the system pressure and flow requires not only intelligent remote monitoring, early warning and control terminals, but also multiple joint control. In the distributed deployment network, master-slave deployment is implemented between intelligent remote monitoring and early warning and control terminals, and real-time data collected according to actual working conditions are summarized, analyzed, and unified control. Such as figure 1 As shown, for example, when the pool of a No. 2 water outlet is full and the water level of the pool exceeds the high water level, an alarm signal is sent. At this time, the data platform of the monitoring center will analyze and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com