Vibration deep soil-loosening fertilizer applicator

A fertilizer applicator and subsoiling technology, applied in the field of agricultural machinery, can solve the problems of increasing plow forward resistance, unfavorable water and nutrient absorption, and increased fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

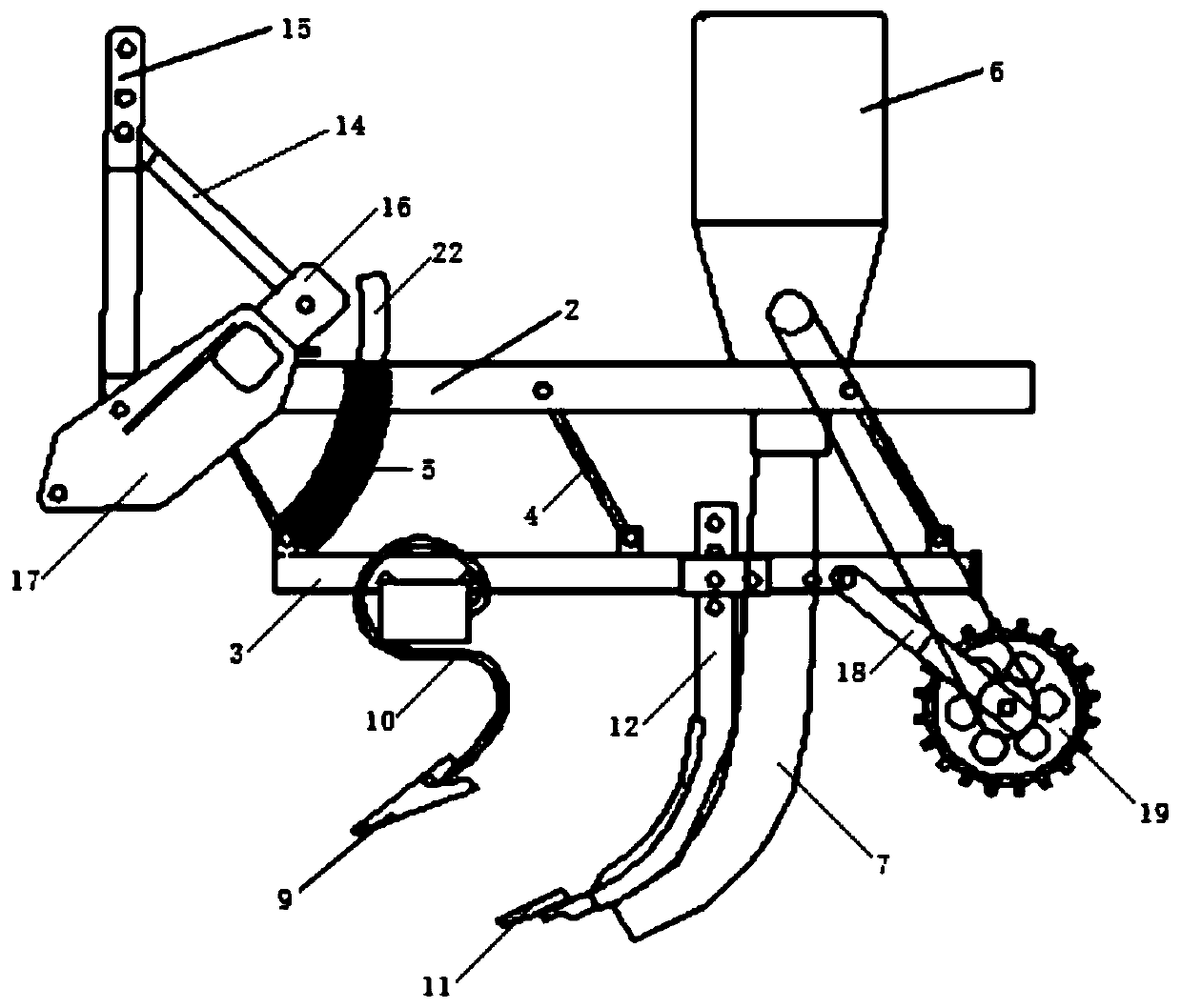

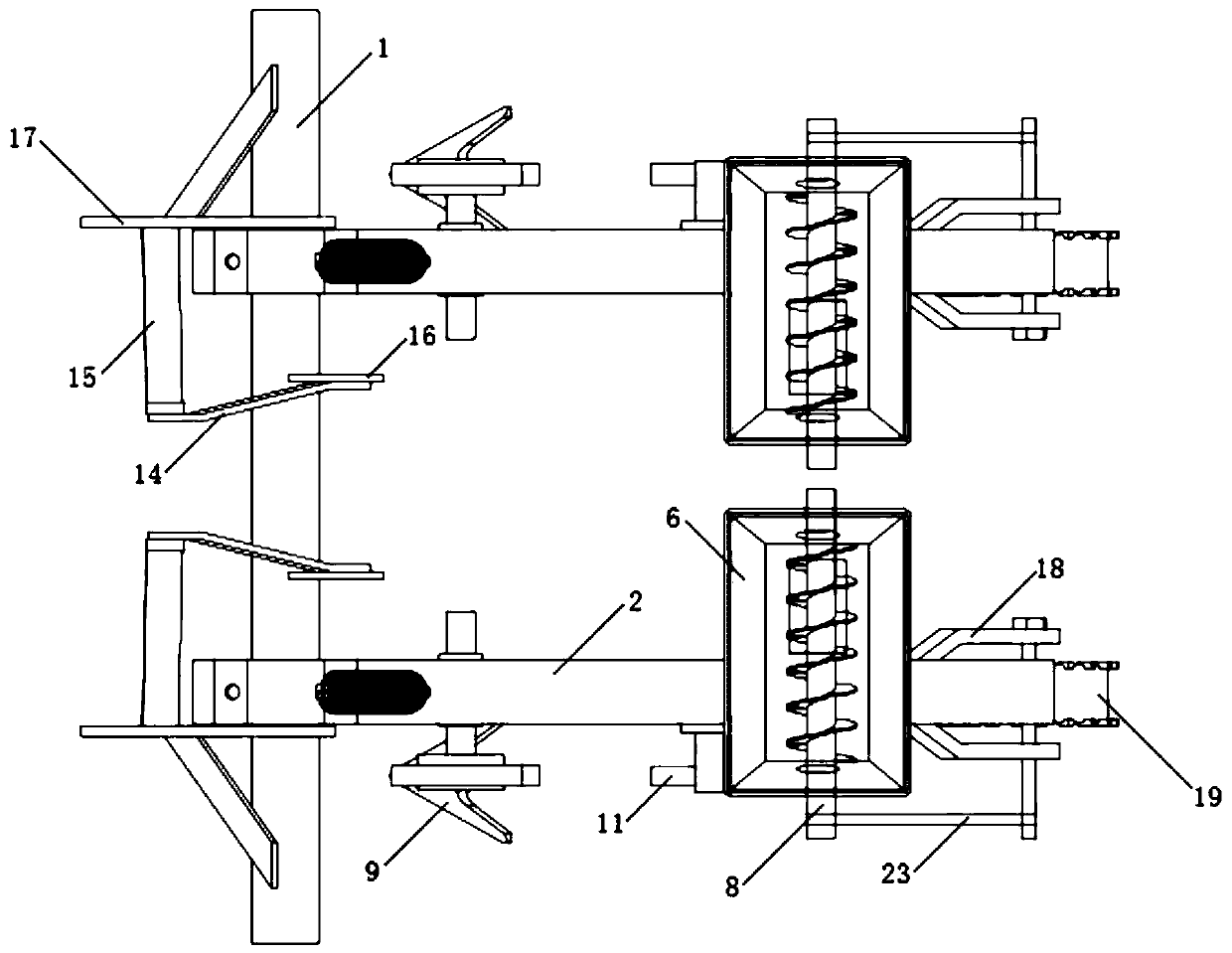

[0069] This embodiment provides a vibrating subsoiling fertilizer applicator, comprising a frame, a spring tooth type subsoiling part for loosening the upper layer of soil is provided at the bottom of the frame, and a spring tooth type subsoiling part is provided with a useful Rigid subsoiling parts for loose substratum soil, elastic teeth subsoiling parts and rigid subsoiling parts are all fixed on the frame, and there is a material deep burying mechanism fixed on the frame behind the rigid subsoiling parts for deep fertilization ;

[0070] Described elastic tooth type subsoiler comprises two-wing shovel 9 and elastic shovel handle 10, and two-wing shovel 9 is fixed on the lower end of elastic shovel handle 10, and elastic shovel handle 10 is fixed on the frame;

[0071] Described material deep burying mechanism comprises material box 6, and material box 6 is fixed on the frame, and the bottom of material box 6 is provided with the auger 8 that is used to control blanking, an...

Embodiment 2

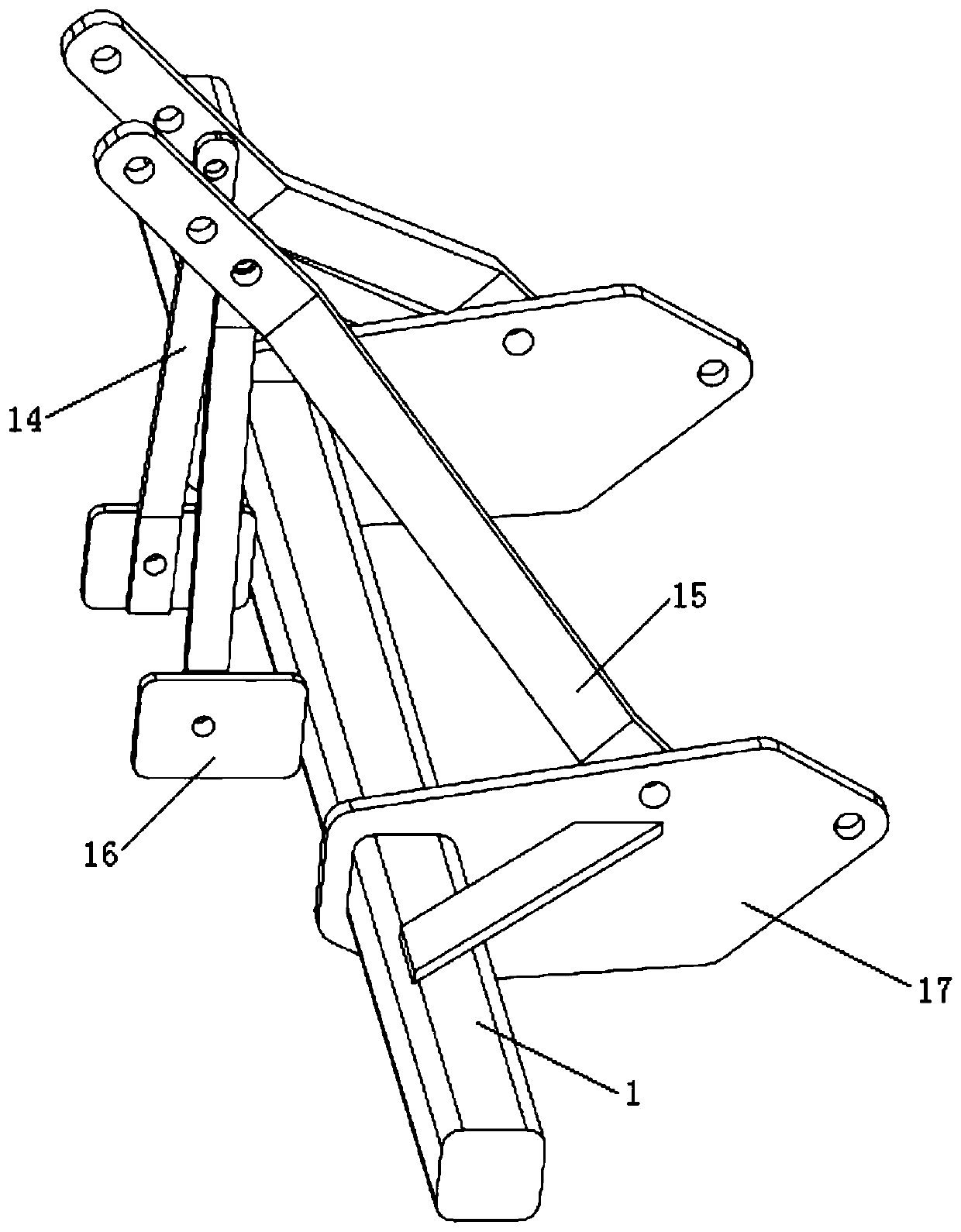

[0081] The present embodiment is based on embodiment 1, and the frame includes a suspension mechanism and a parallel four-bar mechanism; the suspension mechanism is connected with a tractor used to drive the subsoiling fertilizer spreader; the parallel four-bar mechanism includes an upper support beam 2 , the upper support beam 2 is connected with the suspension mechanism, the upper support beam 2 is provided with a lower support beam 3 parallel to it up and down with the terrain, and the upper support beam 2 and the lower support beam 3 are provided with a parallel four bar The pull rod 4 of the mechanism; the spring tooth type subsoiler and the rigid subsoiler are connected as one and fixed on the lower support beam 3; the material box 6 is fixed on the upper support beam 2 .

[0082] Also be provided with spring 5 between described upper support beam 2 and lower support beam 3, spring 5 is sleeved on the spring pull rod 22, the lower end of spring pull rod 22 is hinged with ...

Embodiment 3

[0088] This embodiment is based on Embodiment 1. The double-wing shovel 9 is a triangular double-wing shovel, and the elastic shovel handle 10 is an S-shaped spring-tooth subsoiling shovel handle.

[0089] The elastic shovel handle of this application is an S-shaped spring-tooth subsoiling shovel handle. During the cultivation process, due to the S-shaped characteristics of the elastic shovel handle and the influence of soil resistance and other factors, the elastic shovel handle swings the most and vibrates at the tooth tip. strongest.

[0090] The tillage process of spring-tooth subsoilers can be summarized as follows: the soil resistance increases, causing the deformation of the spring teeth to accumulate energy. When the elastic potential energy of the spring teeth reaches the maximum, the soil yield limit is reached, and the energy is released rapidly to loosen the soil. Therefore, the increase in soil resistance Constant change is the main reason for the vibration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com