Method for producing Lycium ruthenicum Murr. juice by utilizing ultra-high pressure processing

A technology of black fruit wolfberry juice and ultra-high pressure technology, which is applied in the fields of application, food science, food preservation, etc., can solve the problems of destroying anthocyanins and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

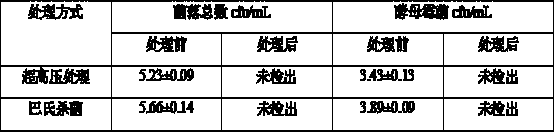

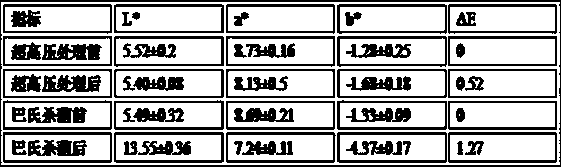

[0023] Utilizing ultra-high pressure technology to produce black fruit wolfberry juice and evaluate its quality

[0024] 1. Using ultra-high pressure technology to produce black fruit wolfberry juice:

[0025] 1) Preparation of black wolfberry juice: fresh black wolfberry juice is selected, cleaned, squeezed twice, filtered twice with four layers of gauze, centrifuged at 4°C, 2000 r / min for 10 minutes, and then bottled Packed in 100mL sealed high-pressure PE bottle.

[0026] 2) Ultra-high pressure treatment: put the canned black fruit wolfberry juice in the ultra-high pressure treatment equipment, at room temperature, the treatment pressure is 400 MPa, 10min, and the average pressure increase rate of the ultra-high pressure treatment is 100-200 MPa / min , the average pressure relief rate of ultra-high pressure treatment is 300-500 MPa / min. The black fruit Lycium barbarum juice obtained by the above method was stored at 4°C.

[0027] 3) Other methods of treatment: pasteurizat...

Embodiment 2

[0042] Production of black fruit wolfberry juice by ultra-high pressure technology, and its storage quality evaluation

[0043] 1. Using ultra-high pressure technology to produce black fruit wolfberry juice:

[0044]1) Preparation of black wolfberry juice: fresh black wolfberry was selected, cleaned, squeezed twice, filtered twice with four layers of gauze, centrifuged at 4°C, 2000 r / min for 10 minutes, and then bottled Packed in 100mL sealed high-pressure PE bottle.

[0045] 2) Ultra-high pressure treatment: put the canned black fruit wolfberry juice in the ultra-high pressure treatment equipment, at room temperature, the treatment pressure is 400 MPa, 10min, and the average pressure increase rate of the ultra-high pressure treatment is 100-200 MPa / min , the average pressure relief rate of ultra-high pressure treatment is 300-500 MPa / min. The black fruit Lycium barbarum juice obtained by the above method was stored at 4°C.

[0046] Other methods of processing: pasteurizati...

Embodiment 3

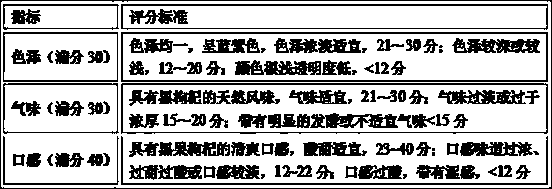

[0059] Sensory Identification Evaluation Test

[0060] Evaluation method: using the difference test method.

[0061] Evaluation requirements: Environmental requirements: Tasting area: The sensory evaluation site is divided into several areas according to the number of evaluators, room temperature: 20°C, light source: all white fluorescent lamps; preparation area: used for preparing samples and distributing samples; equipped with heating, heat preservation facilities and storage facilities, Experiment table, exhaust system; discussion area: used to focus on explaining the evaluation requirements before the evaluation and presenting, discussing and explaining the results after the evaluation.

[0062] Sample preparation: The black fruit wolfberry juice prepared by ultra-high pressure treatment in Reference Example 1 was divided into 3 batches, and the samples were marked as sample 1, sample 2, and sample 3. Reference Example 1 Pasteurized black fruit wolfberry juice 3 batches, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com