Device for intensifying absorption of industrial foul waste gas and using method thereof

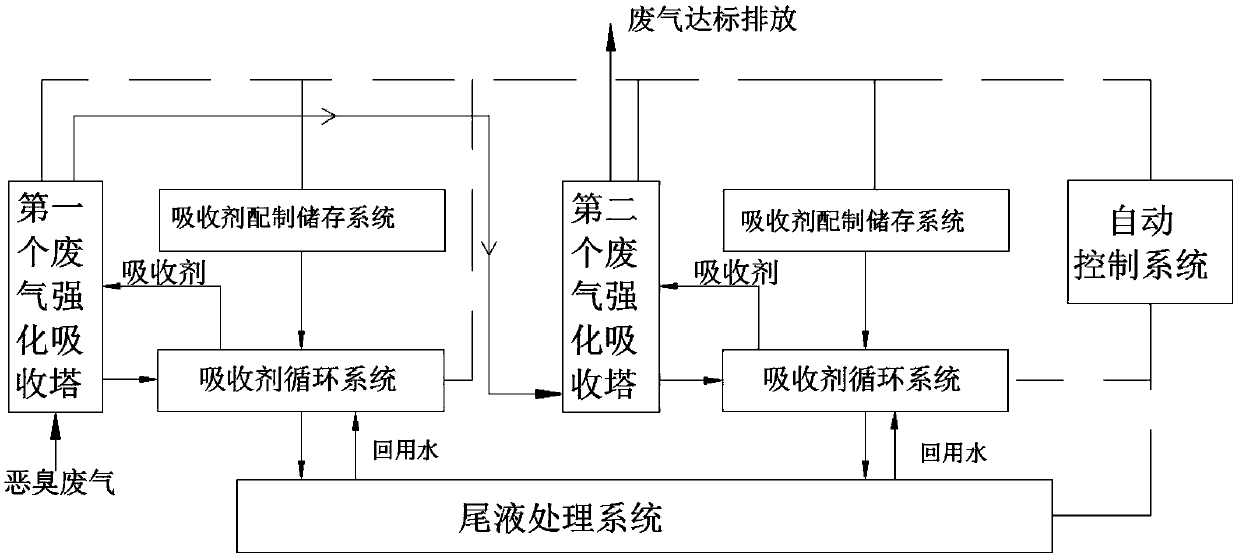

A technology to strengthen absorption and waste gas, which can be used in chemical instruments and methods, separation methods, and dispersed particle separation, and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

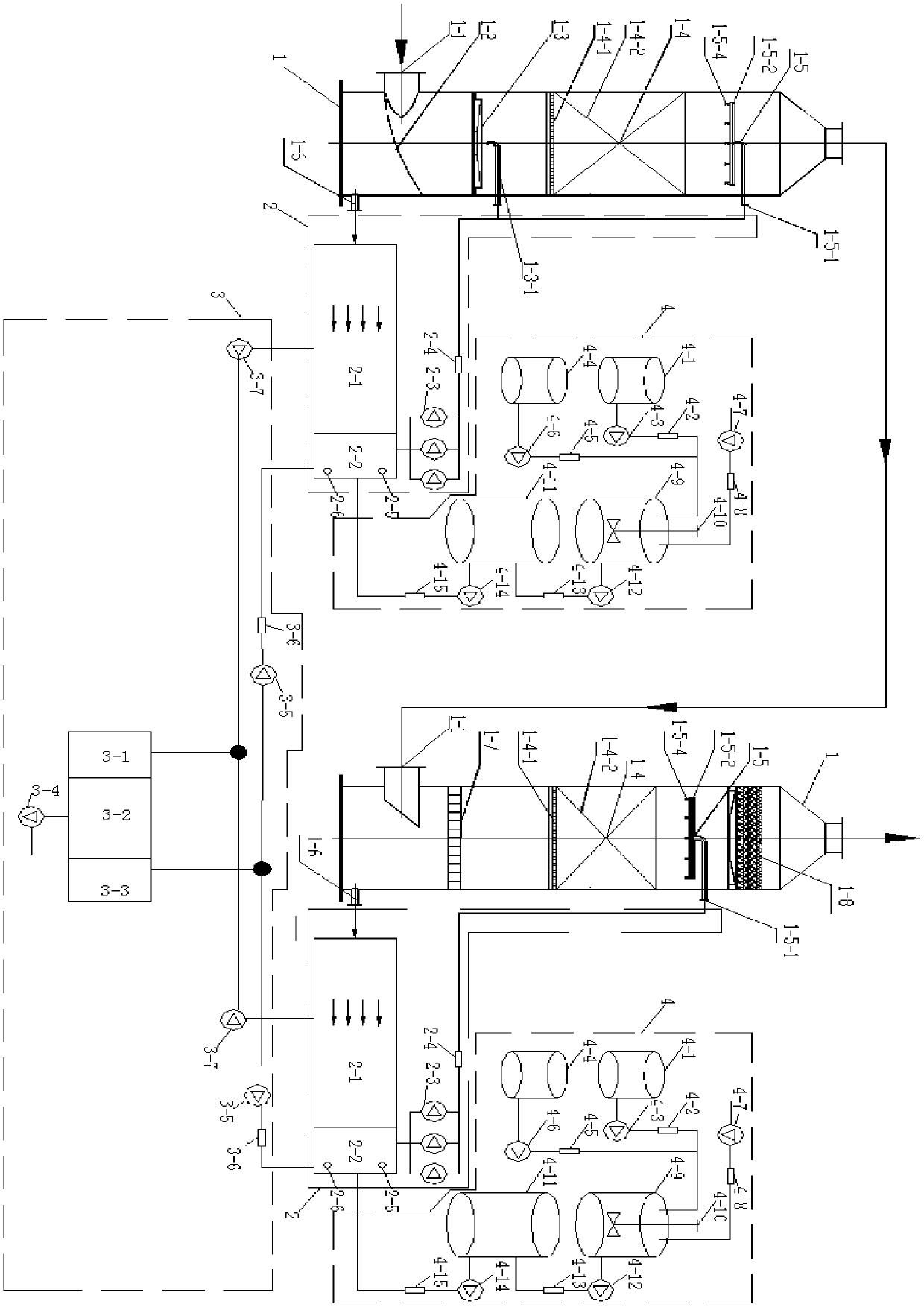

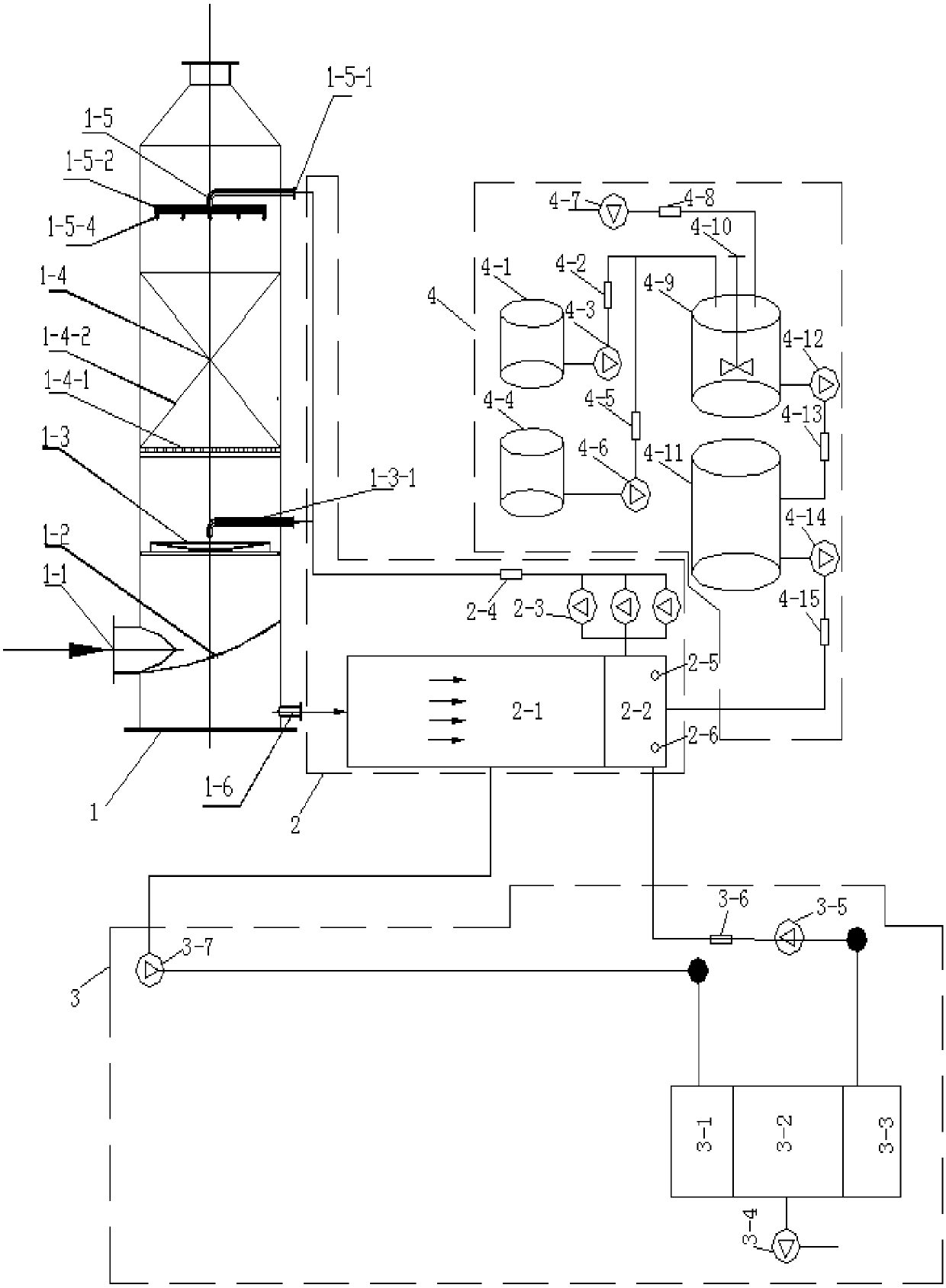

[0048] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0049] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0050] 1 is the enhanced absorption tower, 2 is the absorbent circulation system, 3 is the tail liquid treatment system, 4 is the absorbent preparation storage system, 1-1 is the inlet pipe, 1-2 is the centrifugal inlet section, 1-3 is the cyclone Plate section, 1-4 is the filler absorption section, 1-5 is the spray absorption section, 1-6 is the drain pipe, 1-7 is the uniform air distribution section, 1-8 is the defogging absorption section, 1-3- 1 is the swirl liquid inlet pipe, 1-3-2 is the blind plate, 1-3-3 is the vane, 1-3-4 is the cover tube, 1-3-5 is the support plate, 1-3-6 is the liquid Membrane forming baf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap