Hydrogenation catalyst and preparation method thereof

A technology of hydrogenation catalyst and alumina, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., and can solve the problems of metal and other impurities such as clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

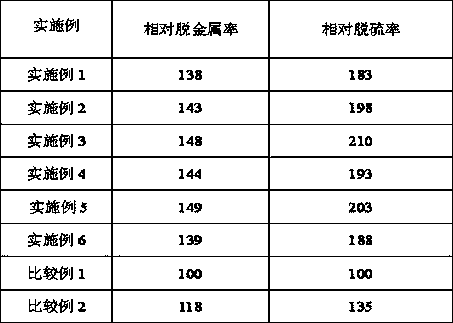

Examples

Embodiment 1

[0054] (1) Prepare mixed solution

[0055] Dissolve 171.7g of ferric nitrate and 37.0g of ammonium dihydrogen citrate in water to prepare 2200mL mixed solution A, in which the concentration of ferric nitrate is 0.08g / mL and the concentration of ammonium dihydrogen citrate is 0.018g / mL.

[0056] (2) Carrier preparation

[0057] 1000g of small-pore alumina is made into spherical particles by rolling in a ball rolling machine. During the ball forming process, 1200mL of mixed solution A is sprayed at the same time. The speed of the ball rolling machine is 35 rpm. After the ball forming is completed, the obtained 0.4~0.5mm spherical alumina A; then weigh 100g of alumina A and put it into the rolling ball machine, sprinkle 700g of macroporous alumina evenly during the rolling process, and spray 840mL of mixed solution A at the same time, the rolling ball machine speed is 35 RPM, after ball forming, 0.8~1.0mm spherical alumina B is produced. Carry out water vapor treatment on alumi...

Embodiment 2

[0064] (1) Prepare mixed solution

[0065] Dissolve 227.3g of ferric nitrate and 53.0g of diammonium hydrogen citrate in water to prepare 1800mL mixed solution A, in which the concentration of ferric nitrate is 0.126g / mL and the concentration of diammonium hydrogen citrate is 0.027g / mL.

[0066] (2) Carrier preparation

[0067] 1000g of small-pore alumina is made into spherical particles by rolling in a ball rolling machine. During the ball forming process, 1200mL of mixed solution A is sprayed at the same time. The speed of the ball rolling machine is 35 rpm. After the ball forming is completed, the obtained 0.6~0.7mm spherical alumina A; then weigh 100g of alumina A and put it into the ball rolling machine, sprinkle 363g of macroporous alumina evenly during the rolling process, and spray 435mL of mixed solution A at the same time, the speed of the rolling ball machine is 35 RPM, after ball forming, 1.0~1.2mm spherical alumina B is produced. Carry out water vapor treatment ...

Embodiment 3

[0074] (1) Prepare mixed solution

[0075] Dissolve 235.7g of ferric nitrate and 59.0g of ammonium citrate in water to prepare 1800mL of mixed solution A, in which the concentration of ferric nitrate is 0.168g / mL and the concentration of ammonium citrate is 0.042g / mL.

[0076] (2) Carrier preparation

[0077] 1000g of small-pore alumina is made into spherical particles by rolling in a ball rolling machine. During the ball forming process, 1200mL of mixed solution A is sprayed at the same time. The speed of the ball rolling machine is 35 rpm. After the ball forming is completed, the obtained 0.8~1.0mm spherical alumina A; then weigh 100g of alumina A and put it into the ball rolling machine, sprinkle 114g of macroporous alumina evenly during the rolling process, and spray 95mL of mixed solution A at the same time, the speed of the ball rolling machine is 35 RPM, after ball forming, 1.0~1.2mm spherical alumina B is produced. Carry out water vapor treatment on alumina B, the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com