Paint special for paperboard coating and paperboard

A coating and cardboard technology, used in paper coating, papermaking, coating, etc., can solve the problems of poor coating surface coverage, high coating dosage, and paper bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

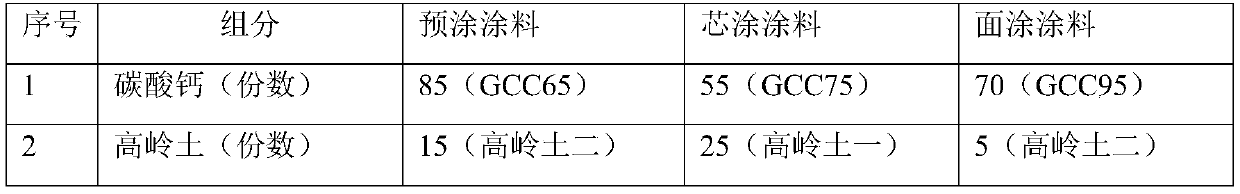

[0048] The mass components of the coating prepared in Example 1 are shown in Table 1.

[0049] Table 1

[0050]

[0051]

[0052] In the present embodiment, GCC65 is 65wt% of particles with particle size less than or equal to 2 μm particle size in heavy calcium carbonate, GCC75 is 75% by weight of particles with particle size of 2 μm particle size or less in heavy calcium carbonate, and GCC95 is small particles in heavy calcium carbonate. The content of particles with a particle size of 2 μm or less is 95% by weight; the whiteness of kaolin 1 is 84%, and the content of particles with a particle size of 2 μm or less is 82% by weight; the whiteness of kaolin 2 is 90%, and the content of particles with a particle size of 2 μm or less is 86% by weight. The whiteness of kaolin 3 is 86%, and the particle size content of less than or equal to 2 μm is 84wt%; 52%, the emulsified particle size is 40-60nm; the esterified starch is acetate coated starch; the liquid caustic soda is ...

Embodiment 2

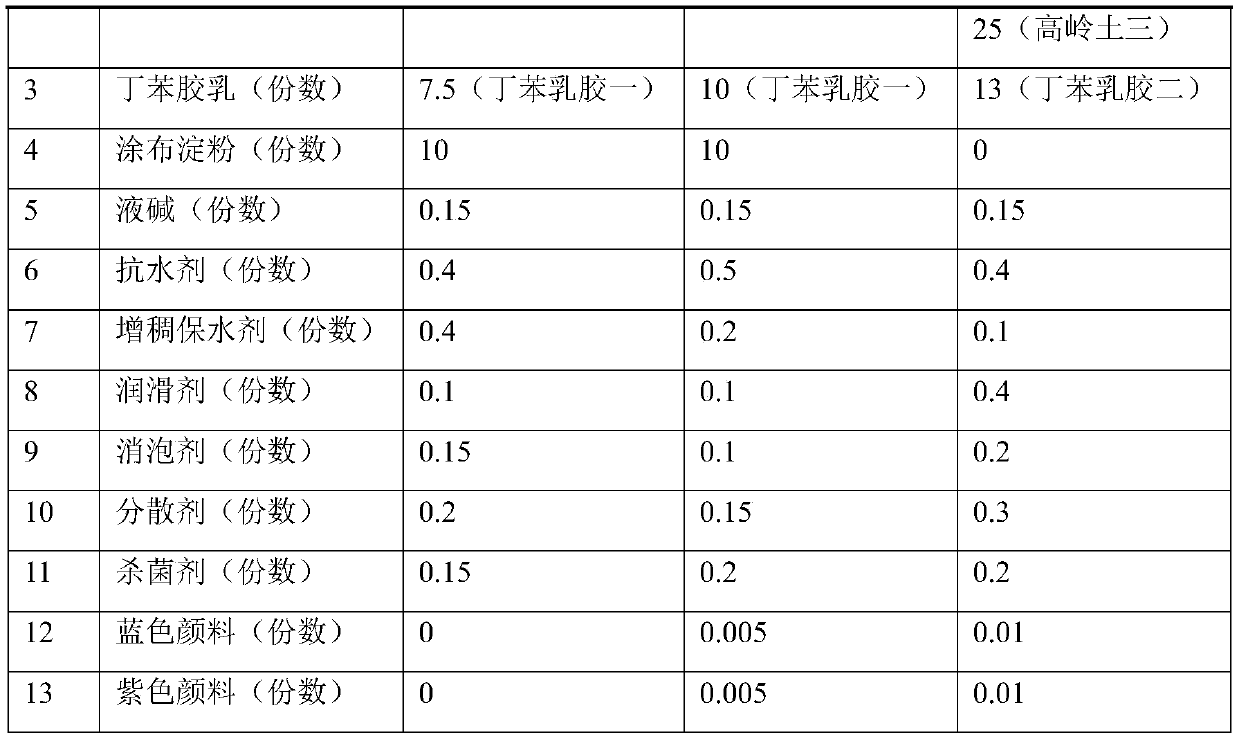

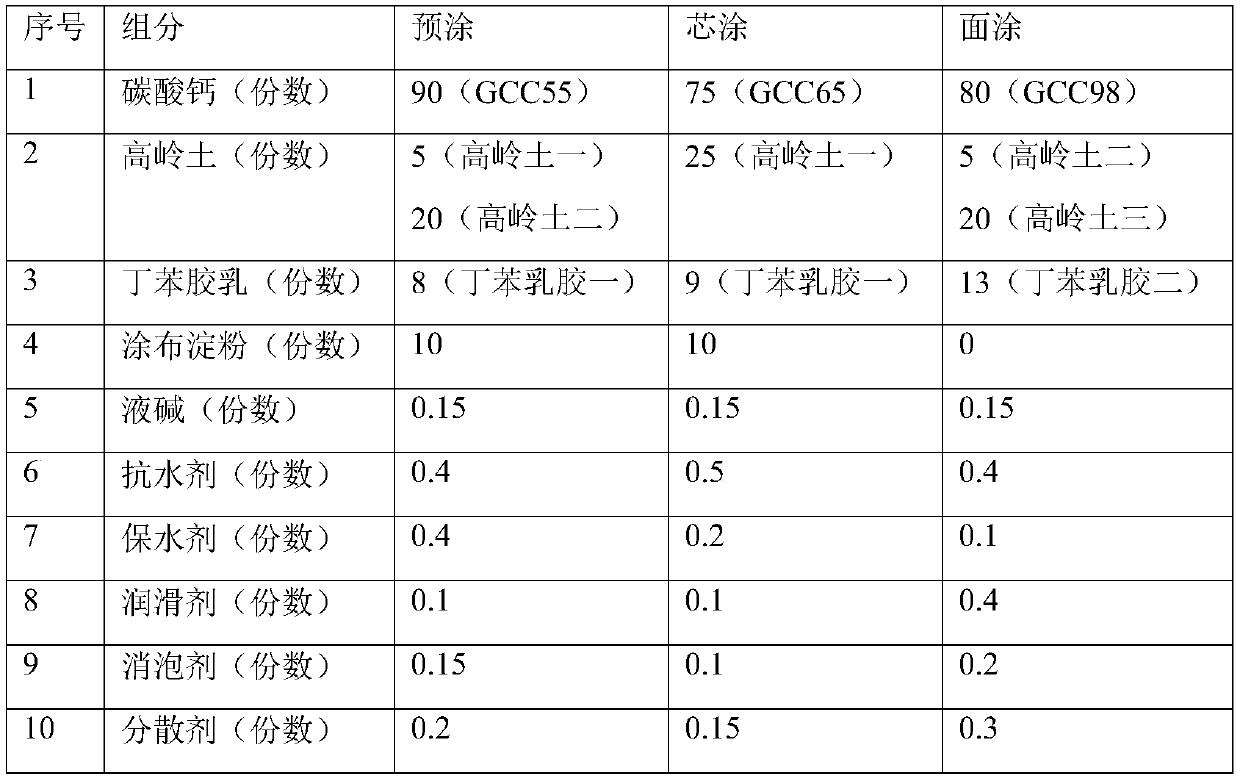

[0059] The mass components of the coating prepared in Example 2 are shown in Table 2.

[0060] Table 2

[0061]

[0062]

[0063]In the present embodiment, GCC55 is 55wt% of particles with particle size less than or equal to 2 μm particle size in heavy calcium carbonate, GCC65 is 65% by weight of particles with particle size of 2 μm particle size or less in heavy calcium carbonate, and GCC98 is small particles in heavy calcium carbonate. The content of particles with a particle size of 2 μm or less is 98% by weight; the whiteness of kaolin 1 is 86%, and the content of particles with a particle size of 2 μm or less is 86% by weight; the whiteness of kaolin 2 is 92%, and the content of particles with a particle size of 2 μm or less is 88% by weight. The whiteness of kaolin 3 is 88%, and the particle size content of less than or equal to 2 μm is 88wt%; the solid content of styrene-butadiene latex 1 is 50-55wt%, the emulsified particle size is 80-120nm, and the solid content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com