High-temperature tail gas combustion assisting combustion device of gas turbine

A gas turbine and combustion device technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as reducing oxygen content and nitrogen oxides NOx, environmental pollution, and reducing the final flue gas emission temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

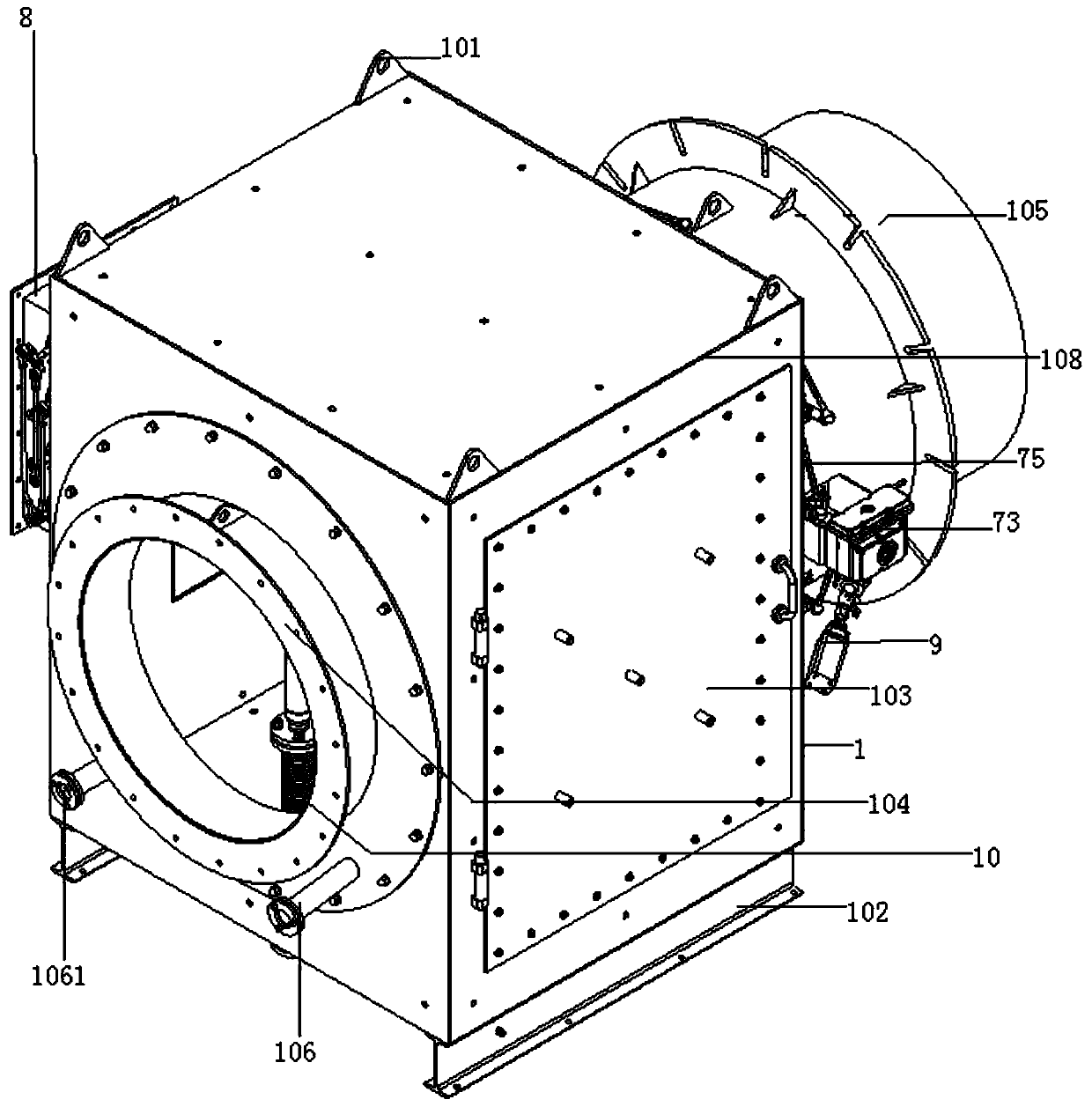

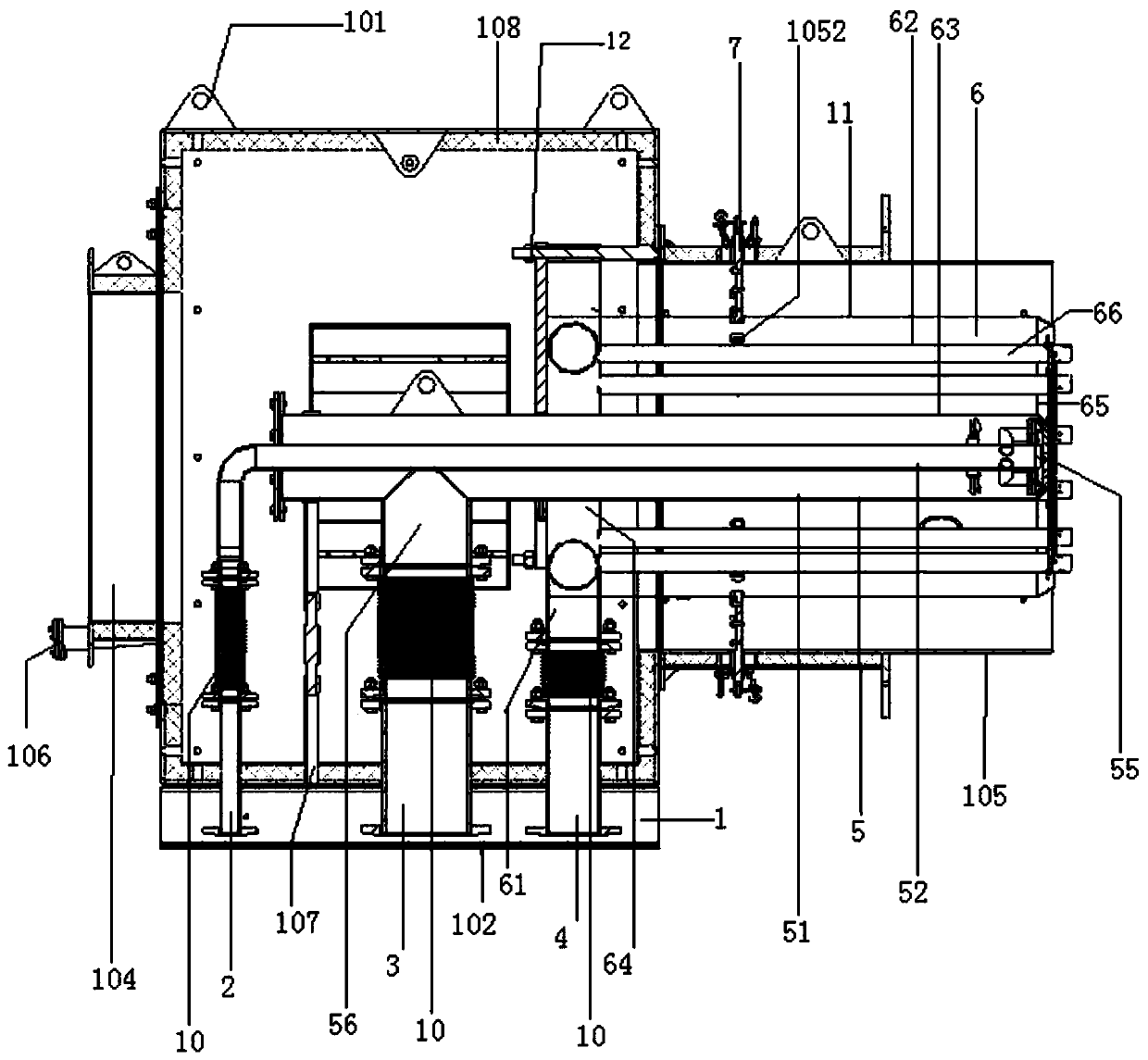

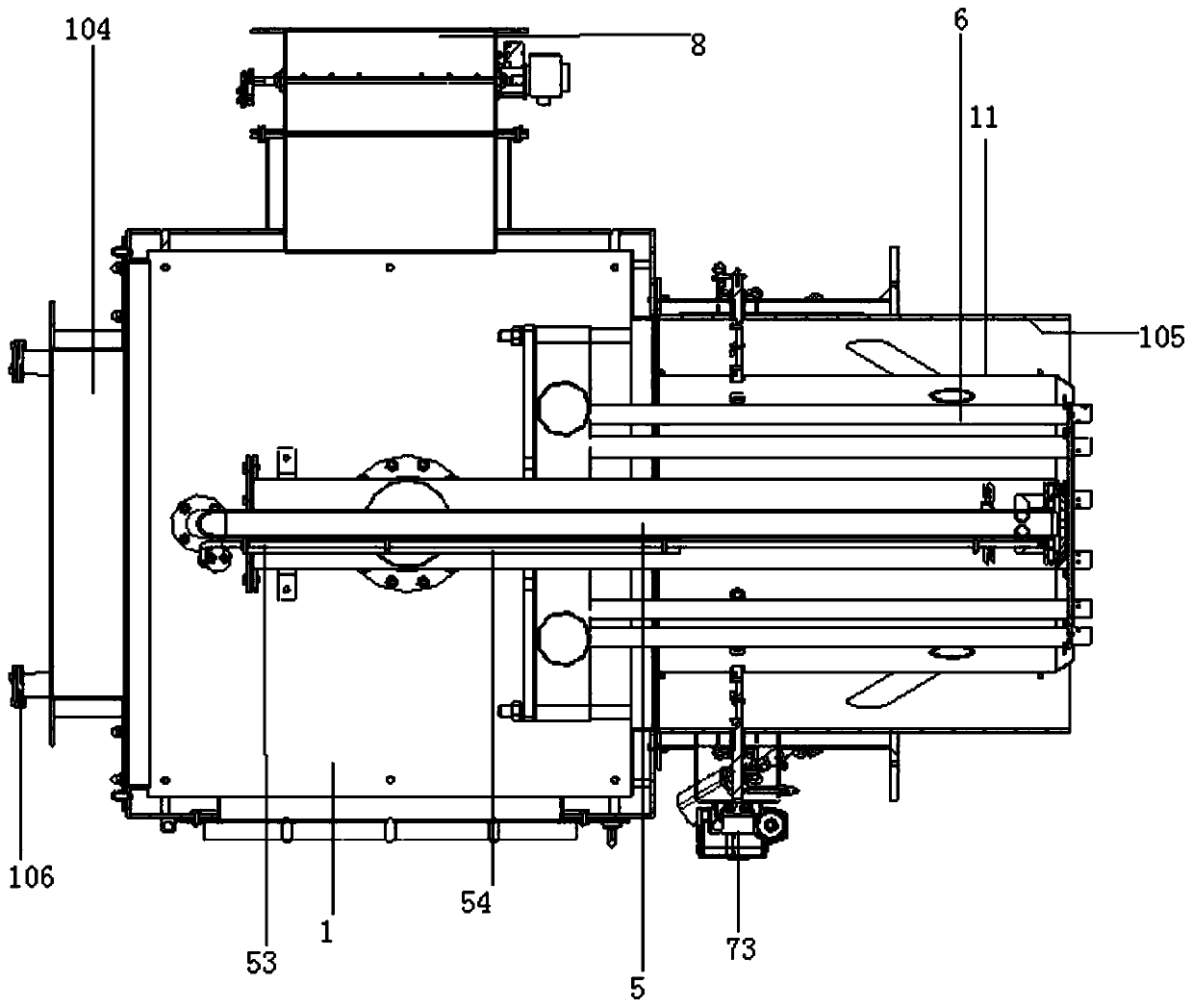

[0022] figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, the gas turbine high-temperature tail gas combustion-supporting combustion device includes a hollow rectangular outer shell 1, a central gas pipe 2 with a flange, a central air pipe 3 and the main gas Pipe 4, central gas burner 5, main gas burner 6, high-temperature flue gas diversion mechanism 7, air pipe with electric damper 8, flame detector 9 (using the existing mature flame detector finished product, the main detection center gas combustion 5, the size of the flame produced when the main gas burner 6 burns); there are lifting lugs 101 around the upper end of the housing 1 (to facilitate the overall hoisting of the equipment), and the lower parts of the front and rear ends are transversely welded with support plates 102; The front, rear, left and right sides of 1 are open structures, and a movable inspection door 103 is hingedly installed on the front side of the housing 1 (open the inspection door for inspection when the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com