Heat pump for realizing non-halt defrosting by using waste heat of water in cylinder sleeve of internal combustion engine

A cylinder liner water, internal combustion engine technology, applied in the direction of internal combustion piston engine, heat pump, combustion engine, etc., can solve the problems of engine power reduction, gas heat pump waste heat output reduction, gas heat pump power output reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

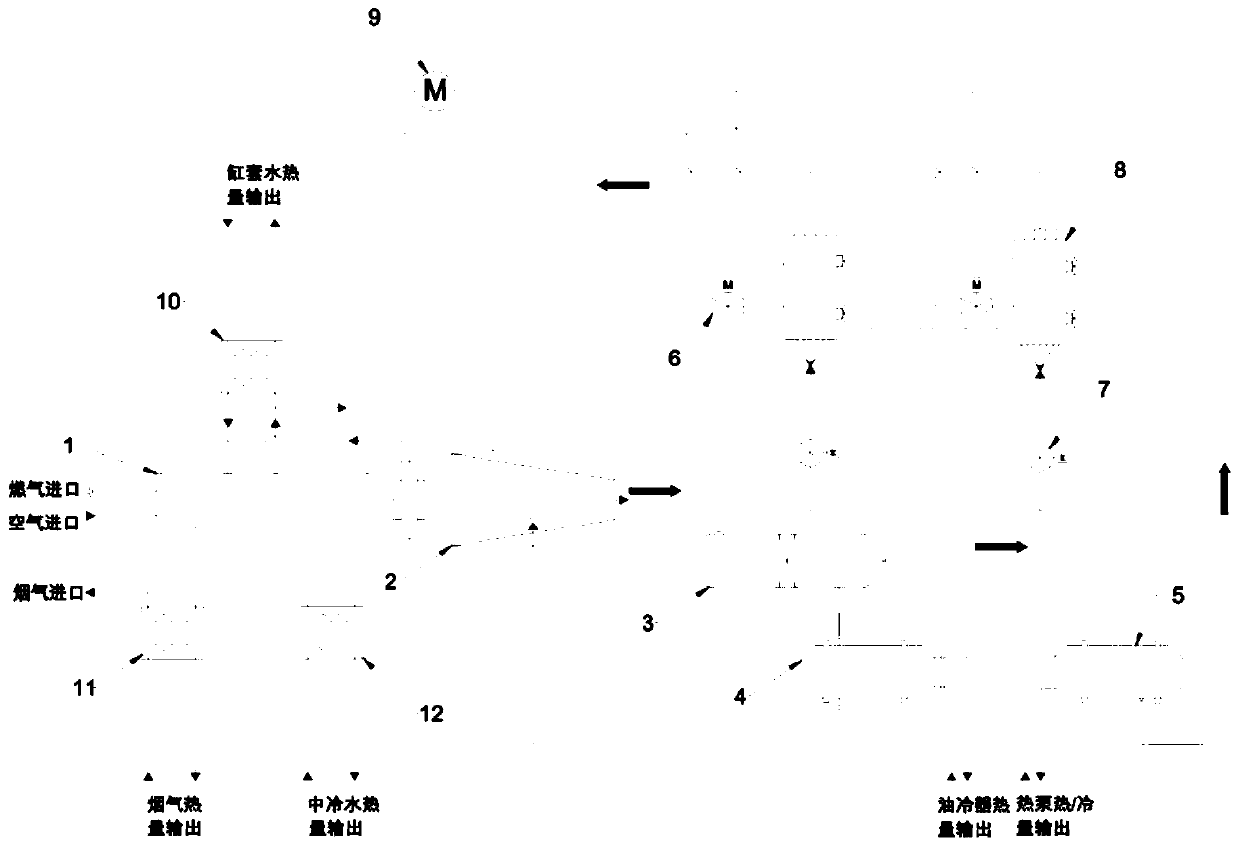

[0051] Such as figure 1 As shown, it is a heat pump for non-stop defrosting of internal combustion engine jacket water waste heat provided by the present invention, driven by natural gas, including gas engine 1, compressor 2, oil separator 3, oil cooler 4, condenser 5, Solenoid valve 6, expansion valve 7, evaporator 8, circulating water pump 9, jacket water heat exchanger 10, flue gas heat exchanger 11, intercooling water heat exchanger 12.

[0052] Among them, the gas engine 1 is used as the driving source; the compressor 2 forms refrigerant gas; the oil component 3 separates lubricating oil and refrigerant; the oil cooler 4 outputs heat to the outside; the condenser 5 forms refrigerant liquid; the solenoid valve 6 is used to start stop bypass; expansion valve 7 is used for throttling control; evaporator 8 performs heat exchange with external air; circulating water pump 9 is used for cylinder jacket water circulation of gas engine; cylinder jacket water heat exchanger 10 is u...

Embodiment 2

[0063] The defrosting operating conditions of the gas heat pump are:

[0064] On the basis of Embodiment 1, when frosting occurs in a certain group of evaporators 8, the corresponding expansion valve 7 is completely closed, the corresponding solenoid valve 6 and the circulating water pump 9 are opened, and the jacket water circulates for heat exchange when it enters the jacket water. Before the evaporator 10, it enters the evaporator 8 that needs defrosting through the circulating water pump 9, and performs defrosting work through the heat of the cylinder jacket water. After the defrosting is completed, close the circulating water pump 9 and the corresponding solenoid valve 6, and open the expansion valve 7 according to the actual situation. Take control and continue the heat pump cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com