Gas chromatograph and detection method for determining content of impurities in hydrogen

A technology of gas chromatograph and impurity content, which is applied in the field of gas chromatograph and detection for the determination of impurity content in hydrogen, and can solve the problems of long time required for detection, error in results, high investment cost of instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

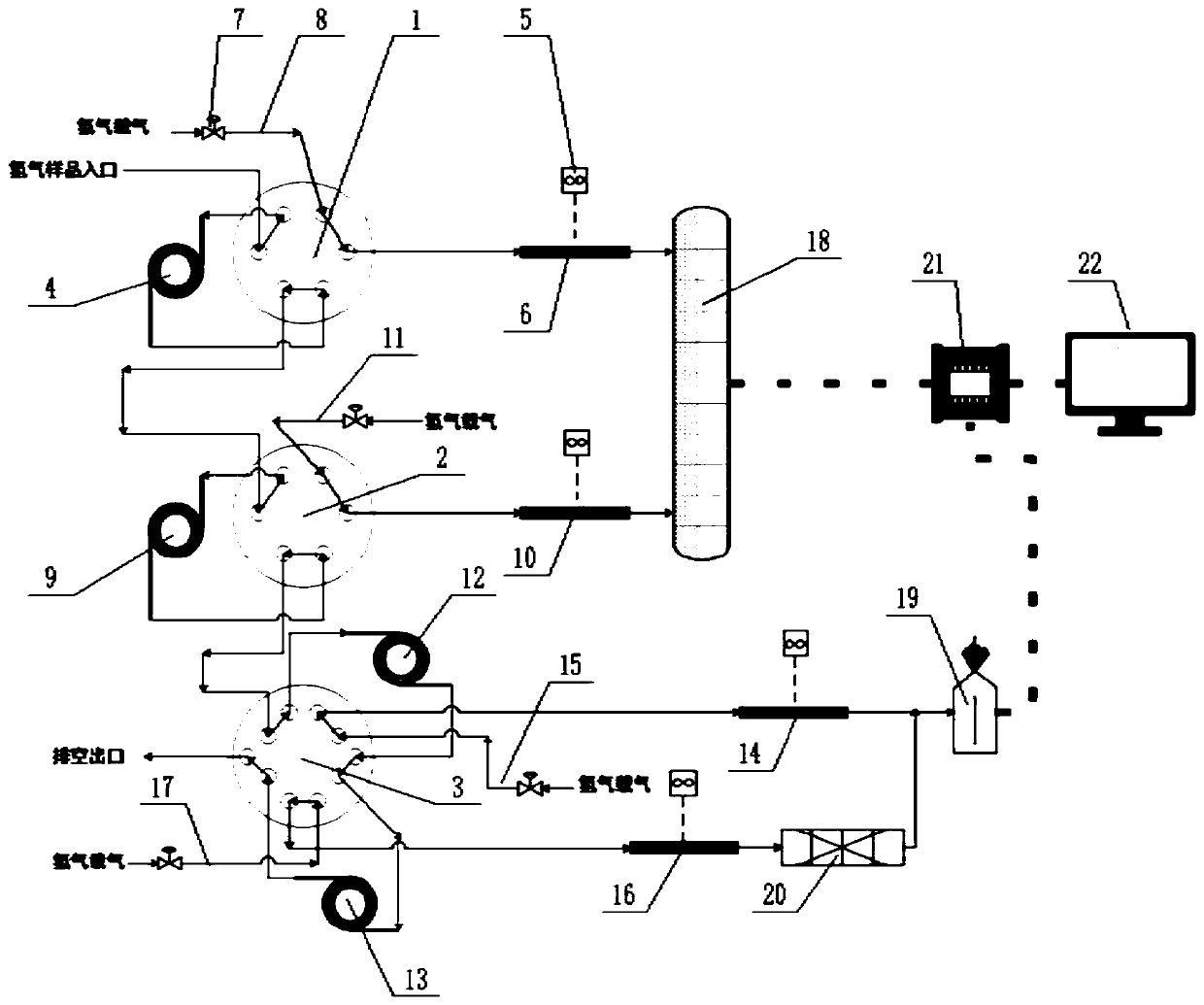

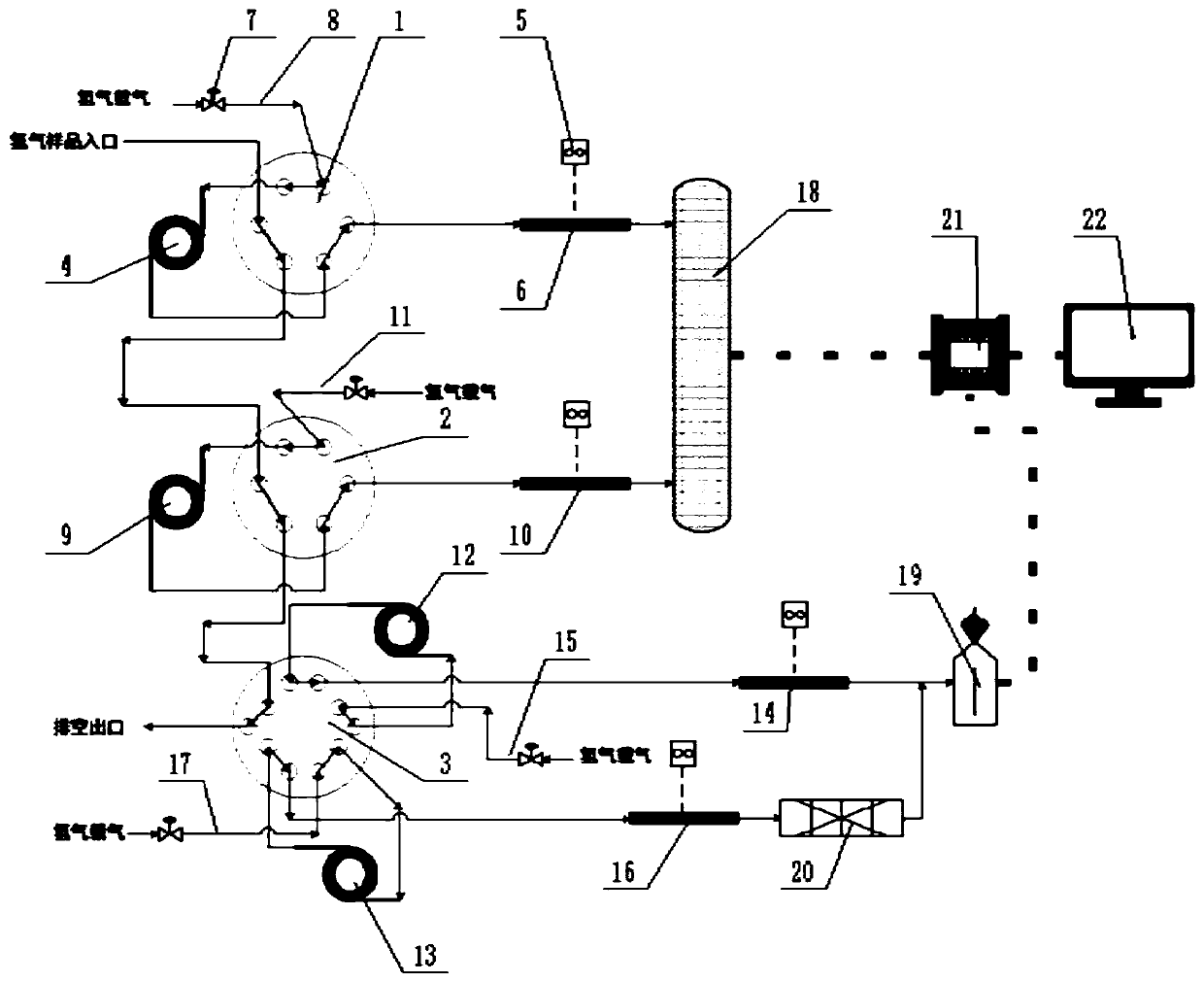

[0033] like figure 1As shown, a gas chromatograph for measuring the content of impurities in hydrogen includes a first pneumatic valve 1, a second pneumatic valve 2, and a third pneumatic valve 3. The first pneumatic valve 1 and the second pneumatic valve 2 are the same as six-way valve, the third pneumatic valve 3 is a ten-way valve; the first pneumatic valve 1 is correspondingly provided with a first quantitative loop 4, a first chromatographic column 6 with a temperature control device 5 and a first carrier gas with an electronic flow controller 7 Pipeline 8, the first chromatographic column 6 is an oxygen-argon separation chromatographic column, preferably an ArDSieve type chromatographic column in this embodiment; the second pneumatic valve 2 is correspondingly provided with a second quantitative loop 9 and a second chromatographic column with a temperature control device 5 10 and the second carrier gas pipeline 11 with electronic flow controller 7, the second chromatogra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com