Manufacturing method of photomask with pattern

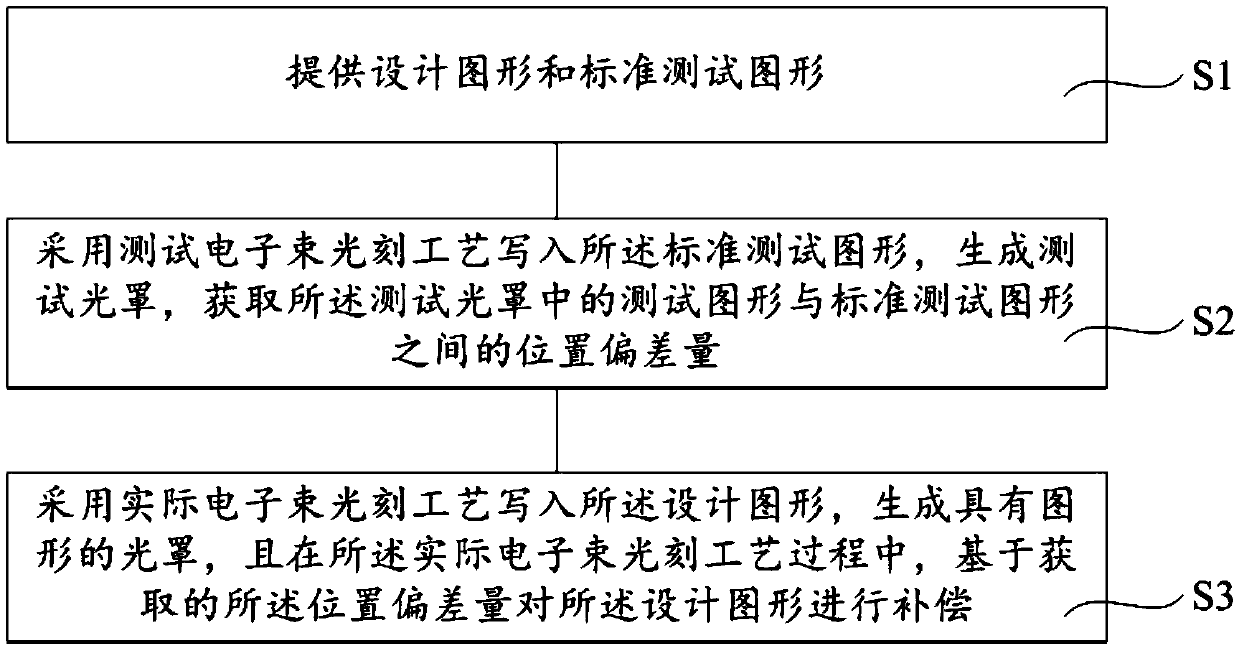

A manufacturing method and graphic technology, applied to the photoplate making process of patterned surface, optics, and originals for photomechanical processing, etc., which can solve the problems that the accuracy of photomask graphics needs to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It can be seen from the background art that the accuracy of the photomask pattern produced by the prior art needs to be improved.

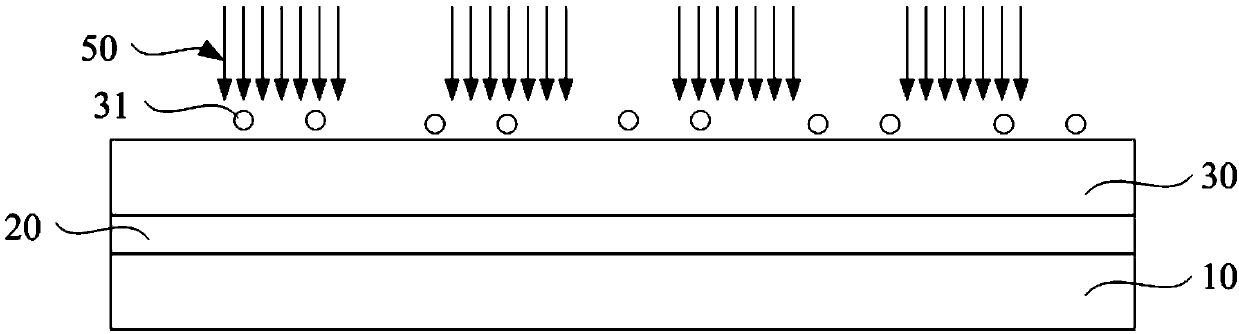

[0015] Now combined with a photomask manufacturing process for analysis, figure 1 and figure 2 It is a structural schematic diagram of a photomask manufacturing process, and the process steps of forming a photomask include: Refer to figure 1 , providing a carrier plate 10 and a mask plate 20 on the carrier plate 10; forming a photoresist layer 30 on the surface of the mask plate 20; transferring the design pattern to the In the photoresist layer 30 , exposure treatment is performed on the photoresist layer 30 .

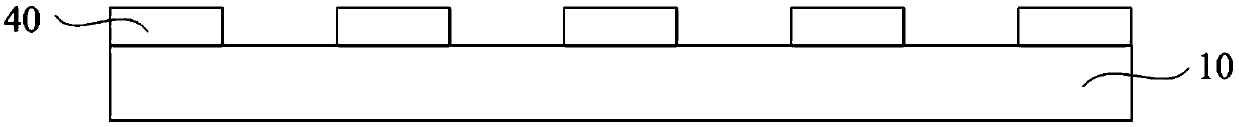

[0016] refer to figure 2 , to the photoresist layer 30 after the exposure treatment (refer to figure 1 ) for developing treatment, exposing part of the mask plate 20 (reference figure 1 ) surface; etching and removing the exposed mask plate 20 to form a patterned photomask 40; removing the photoresist layer 30.

[0017] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com