Capacitively coupled plasma processor and temperature adjusting method thereof

A plasma and capacitive coupling technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as soaring, exceeding process requirements, affecting machine performance, product yield, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

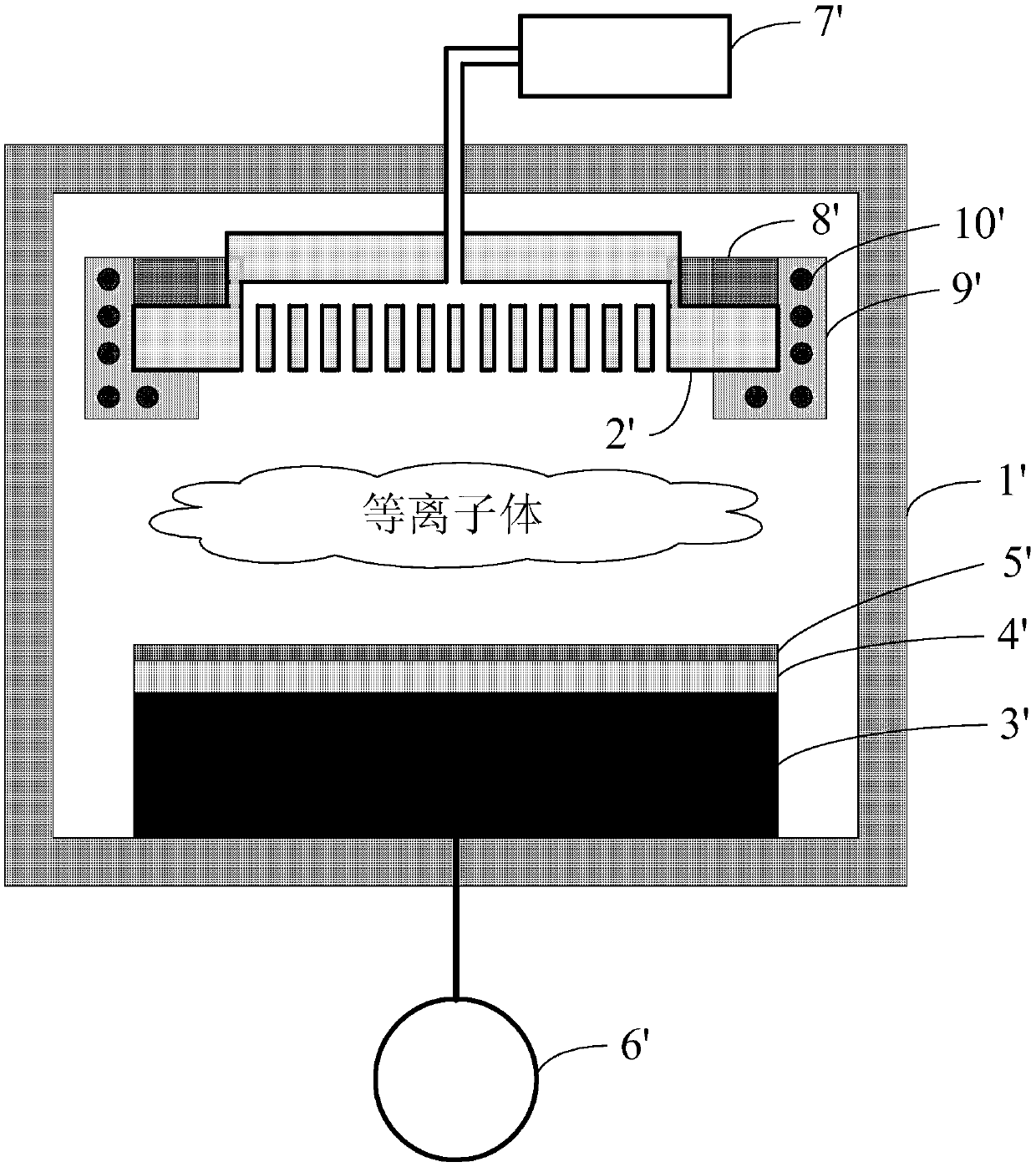

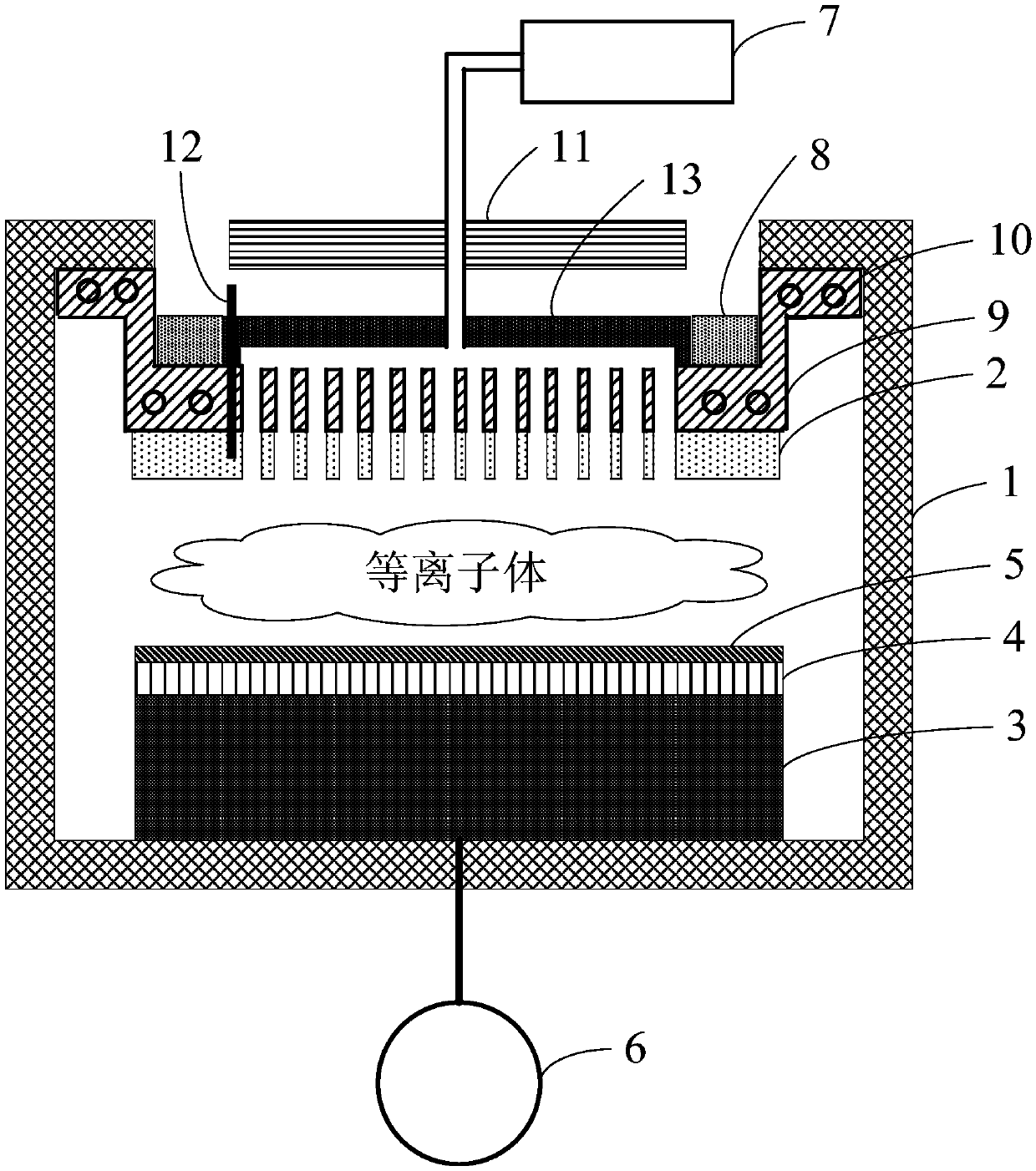

[0019] based on the following figure 2 Preferred embodiments of the present invention will be described in detail.

[0020] Such as figure 2 As shown, the present invention provides a capacitively coupled plasma processor, including a reaction chamber 1, an upper electrode assembly and a lower electrode 3 opposite to the upper electrode assembly are arranged in the reaction chamber 1, and at least one radio frequency power supply 6 is connected to the The upper electrode assembly or the lower electrode 3, RF power is applied to the upper electrode assembly or the lower electrode 3 to form a radio frequency electric field between the upper electrode assembly and the lower electrode 3, and the process gas delivered to the reaction chamber acts on the radio frequency electric field The dissociation is carried out under the hood to form a plasma for etching process or cleaning process. An electrostatic chuck 4 is arranged on the lower electrode 3 , and the substrate 5 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com