Dry desulfurization system and dry desulfurization method

A dry desulfurization and process system technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as equipment damage, high absorbent consumption, and affecting the stability of the circulating fluidized bed dry desulfurization system , to achieve the effects of improving stability, reducing the difficulty of desulfurization, saving investment and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

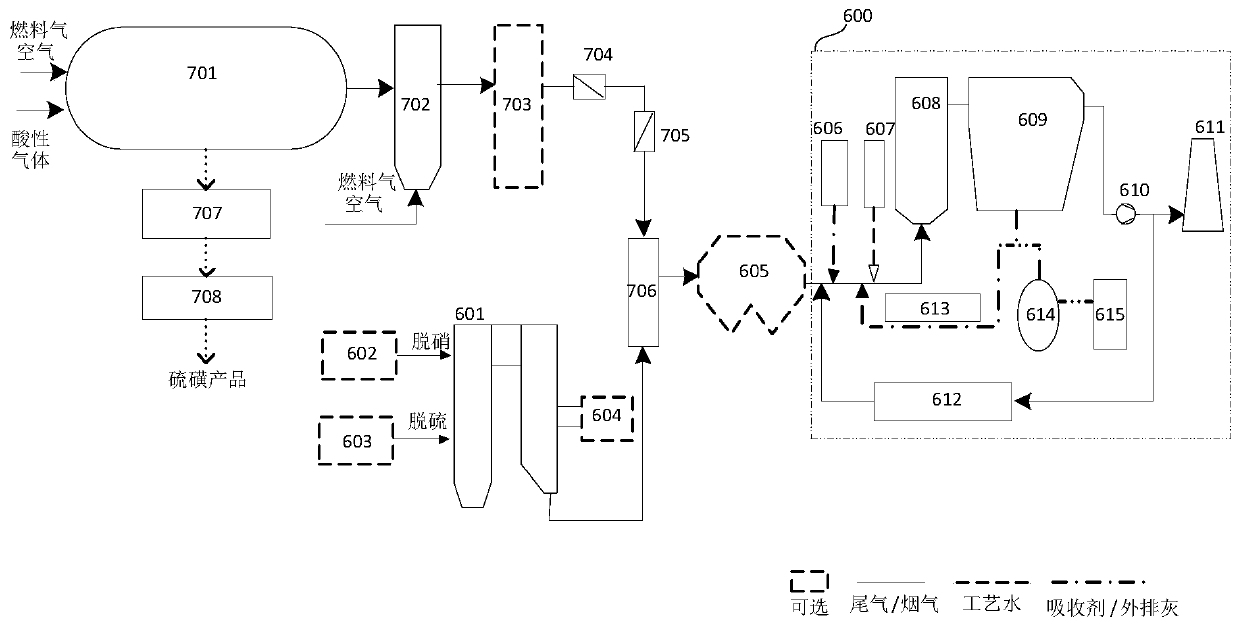

[0044] The first specific embodiment of the present invention provides a dry desulfurization system and a dry desulfurization method, which are suitable for the dry desulfurization process of Claus tail gas coupled with coal-fired boiler flue gas.

[0045] see figure 1 , figure 1 A structural schematic diagram of a dry desulfurization system suitable for Claus tail gas coupled with coal-fired boiler flue gas provided by the first specific embodiment of the present invention.

[0046] The dry desulfurization system includes a coal-fired boiler 601, a flue gas mixer 706, a flue gas circulating fluidized bed device 600 (ie, a flue gas circulating fluidized bed dry desulfurization device) and a Claus process system. in:

[0047] The Claus process system includes a Claus reactor 701, an incinerator 702, an electric windshield 704, a manual windshield 705, a liquid sulfur storage 707, and a sulfur granulator 708. It is also possible to choose whether to install a waste heat utiliz...

no. 2 Embodiment

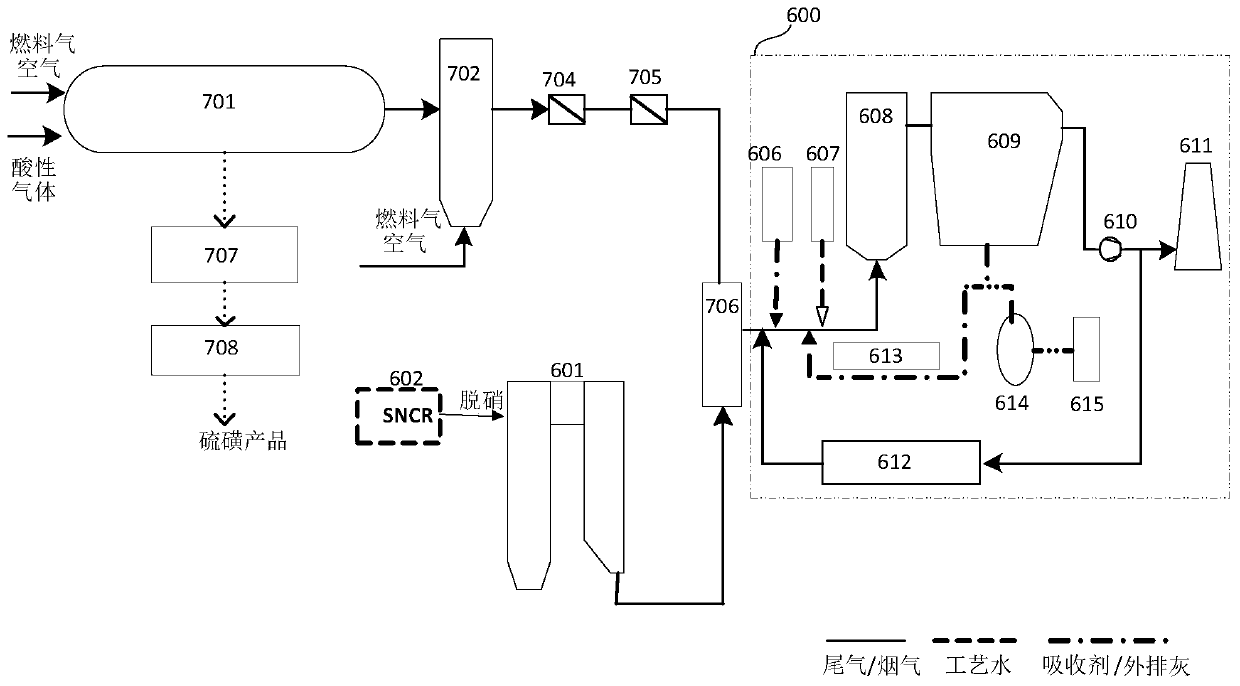

[0071] The second specific embodiment of the present invention provides a dry desulfurization system and a dry desulfurization method, which are suitable for the dry desulfurization process of Claus tail gas coupled with coal-fired boiler flue gas. Please refer to the dry desulfurization system figure 2 , figure 2 A schematic structural diagram of a dry desulfurization system suitable for Claus tail gas coupled with coal-fired boiler flue gas is provided for the second specific embodiment of the present invention; the dry desulfurization method can refer to the above-mentioned first specific embodiment.

[0072] The second specific embodiment of the present invention provides that the dry desulfurization system is a transformation project, see below for details.

[0073] The Claus tail gas desulfurization device in a coal chemical enterprise, its Claus process flow is the traditional two-stage Claus process + SCOT (hydrogenation reduction + MDEA selective absorption) + inci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com