Method for generating high-strength steel corrugated pipe

A technology of high-strength steel and bellows, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of easy cracking and insufficient strength of corrugated parts, etc., and achieve high processing cost, optimized structure, weight reduction, and The effect of small wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a method for producing a high-strength steel bellows.

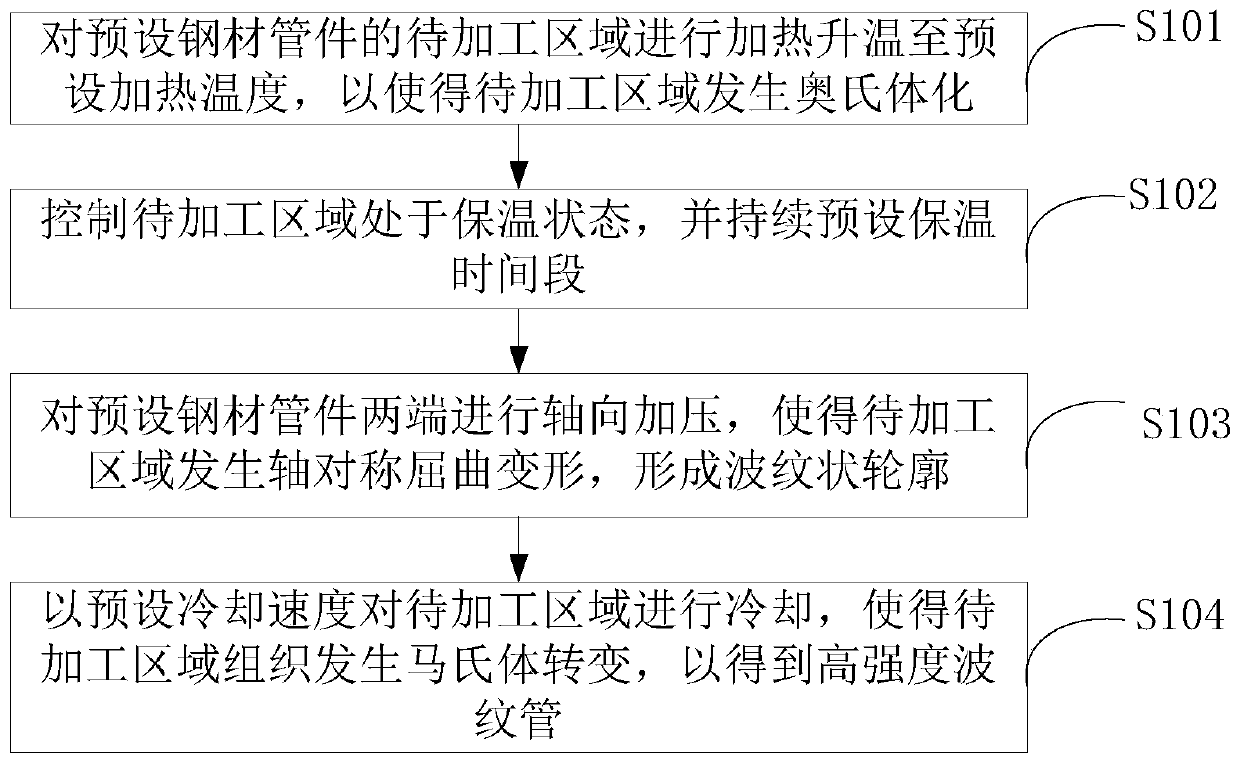

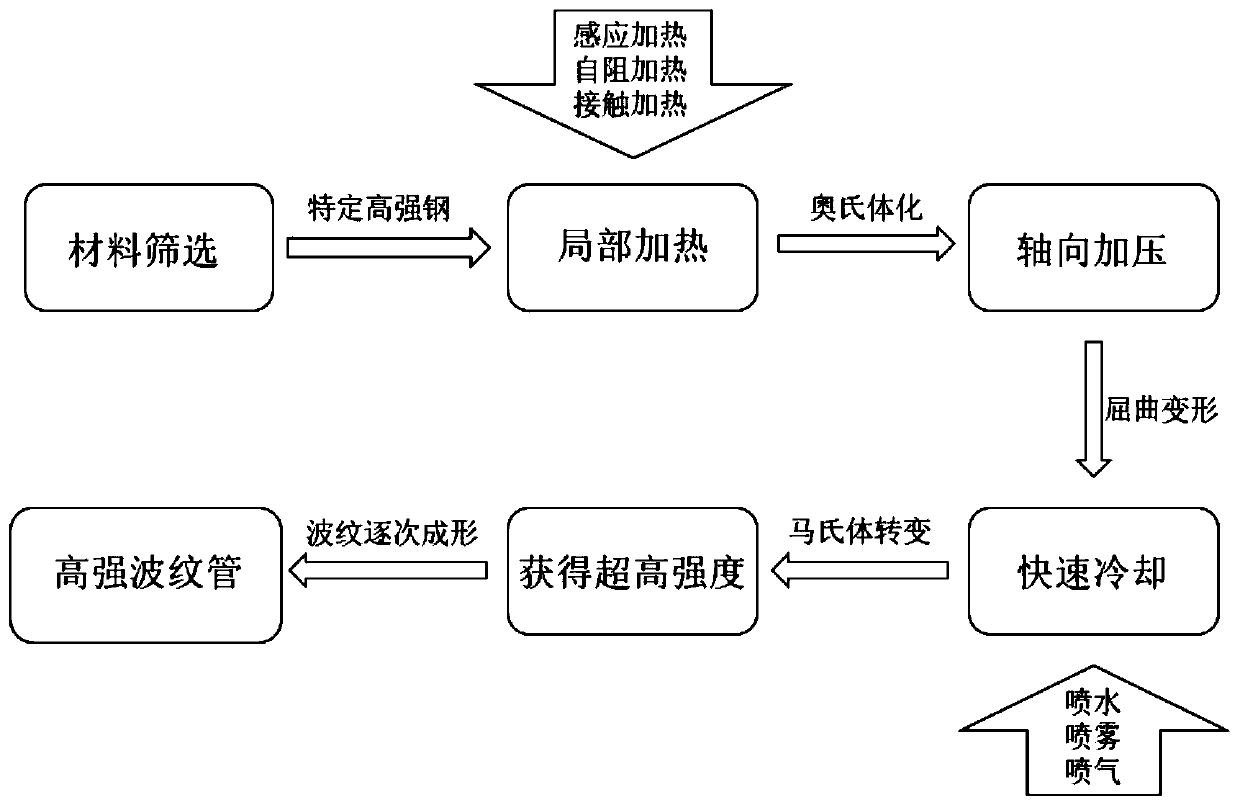

[0028] figure 1 A schematic flow chart showing a method for producing a high-strength steel bellows according to an embodiment of the present invention; figure 2 A process schematic diagram of a method for producing a high-strength steel corrugated pipe according to an embodiment of the present invention is shown. refer to figure 1 and figure 2 As shown, the method for producing a high-strength steel bellows in the embodiment of the present invention includes the following steps.

[0029] It should be noted that the pipes used in this embodiment are all preset steel pipe fittings. In addition, in this embodiment, the preset steel pipe material is ultra-high-strength steel for hot stamping (ie, boron-containing steel), phase transformation induced plasticity steel (ie, TRIP steel,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com