Automatic welding device and welding method with welding gun pose changing in real time

An automatic welding and welding torch technology, which is applied to devices supporting electrode clips, welding equipment, welding accessories, etc., can solve the problems of increasing pre-welding preparation time, tedious manual teaching, and failing to completely eliminate manual teaching procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

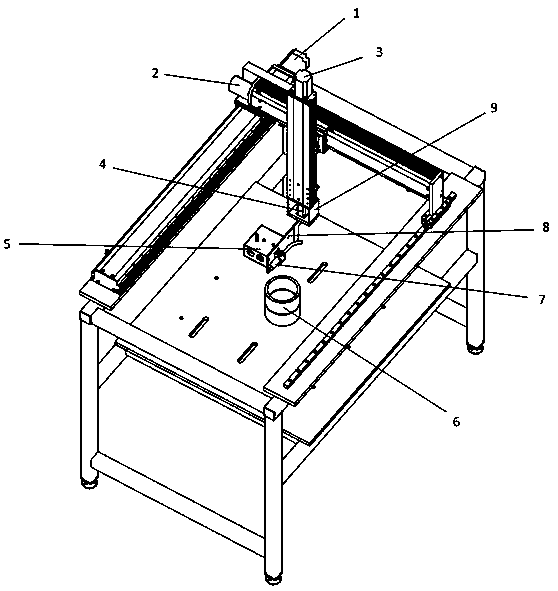

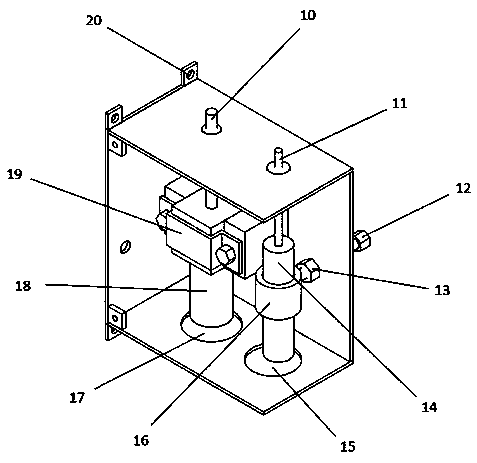

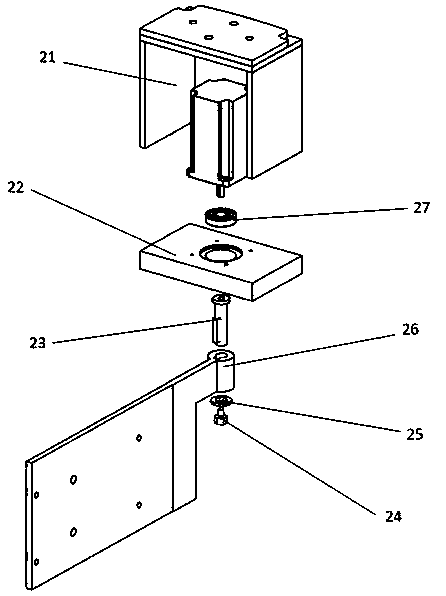

[0105] see Figure 1 to Figure 6 As shown, the automatic welding device for real-time changes in the position and posture of the welding torch of the present invention includes an industrial computer, a gantry-type three-axis welding platform, a laser vision sensor 5, an image acquisition card, a welding torch 7, a welding machine, a motion control cabinet, and a workpiece to be welded 6 Rotate on the welding platform; the present invention provides a method for automatic identification of weld trajectory, in the moving relative coordinate system, segmented fitting of weld trajectory curve, by processing the fitted small section of weld trajectory curve, to obtain Welding torch translation motion control parameters and welding torch pose change control parameters, and then convert the parameters into motion contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com