An ultrasonic vibration gtaw composite device based on acoustic-thermal synchronization and its application method

A technology of ultrasonic vibration and composite device, which is applied in the field of welding metallurgy, can solve the problems that the fixed pressure of each welding cannot be guaranteed, the ultrasonic constant can not be guaranteed, and the ultrasonic input is affected, so as to reduce welding porosity defects and achieve better ultrasonic effect. The effect of improving joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

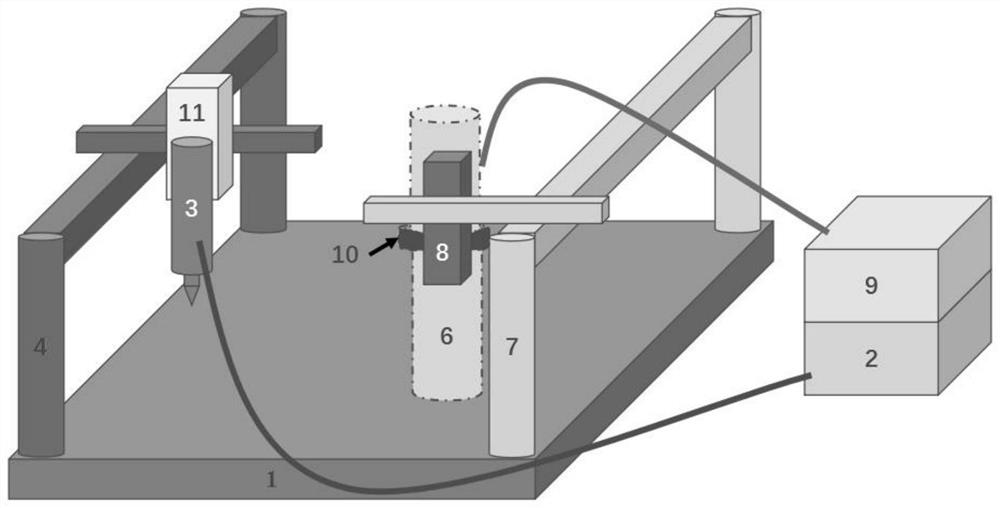

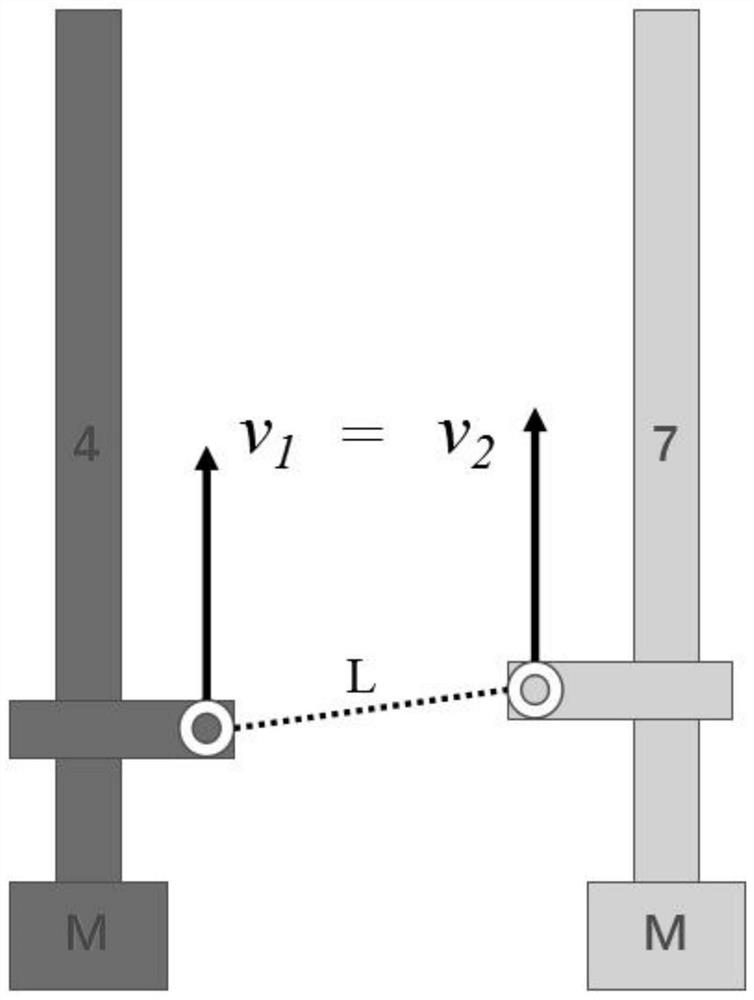

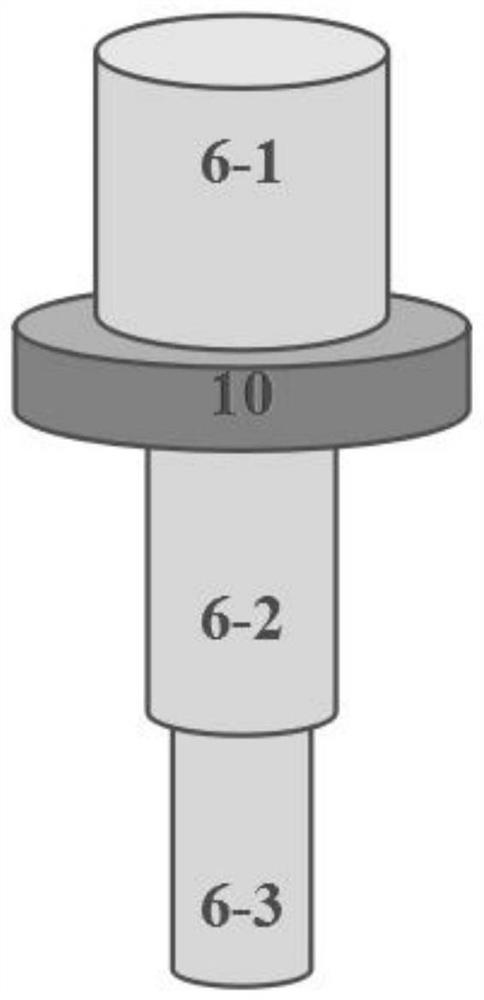

[0030] see Figure 1-5 Describe this embodiment, an ultrasonic vibration GTAW composite device based on acoustic-thermal synchronization, which includes a welding platform 1, a GTAW welding torch 3, a three-dimensional moving platform 4 for the welding torch, an ultrasonic output device 6, a three-dimensional mobile platform 7 for the ultrasonic output device and a pressurized Device 8, the welding torch three-dimensional moving platform 4 is fixedly connected to the welding platform 1, the GTAW welding torch 3 is fixedly connected to the welding torch three-dimensional moving platform 4, the three-dimensional adjustment of the GTAW welding torch 3 is realized through the welding torch three-dimensional moving platform 4, and the ultrasonic output device The three-dimensional mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com