Preparation method of graphite felt loaded metal organic framework compound cathode material and application thereof

A metal-organic framework and metal-loaded technology, which is applied in the direction of iron-organic compounds, chemical instruments and methods, and water treatment of special compounds, can solve the problems of narrow pH range, inability to reduce the amount of addition, slow degradation speed, etc., and achieve wide pH Scope of application, excellent chemical stability, effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

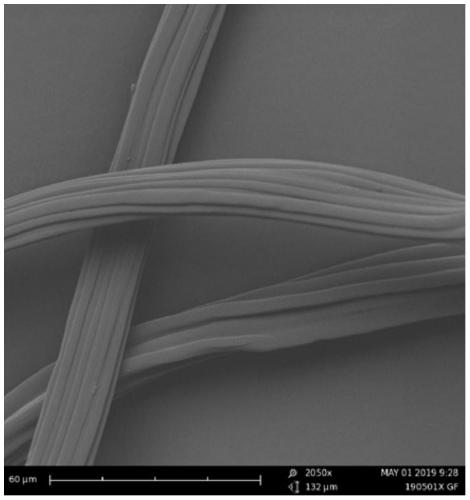

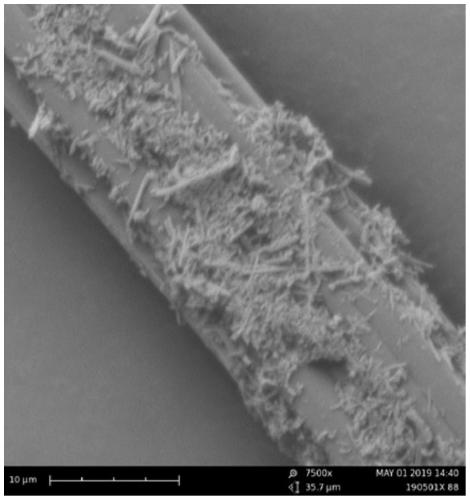

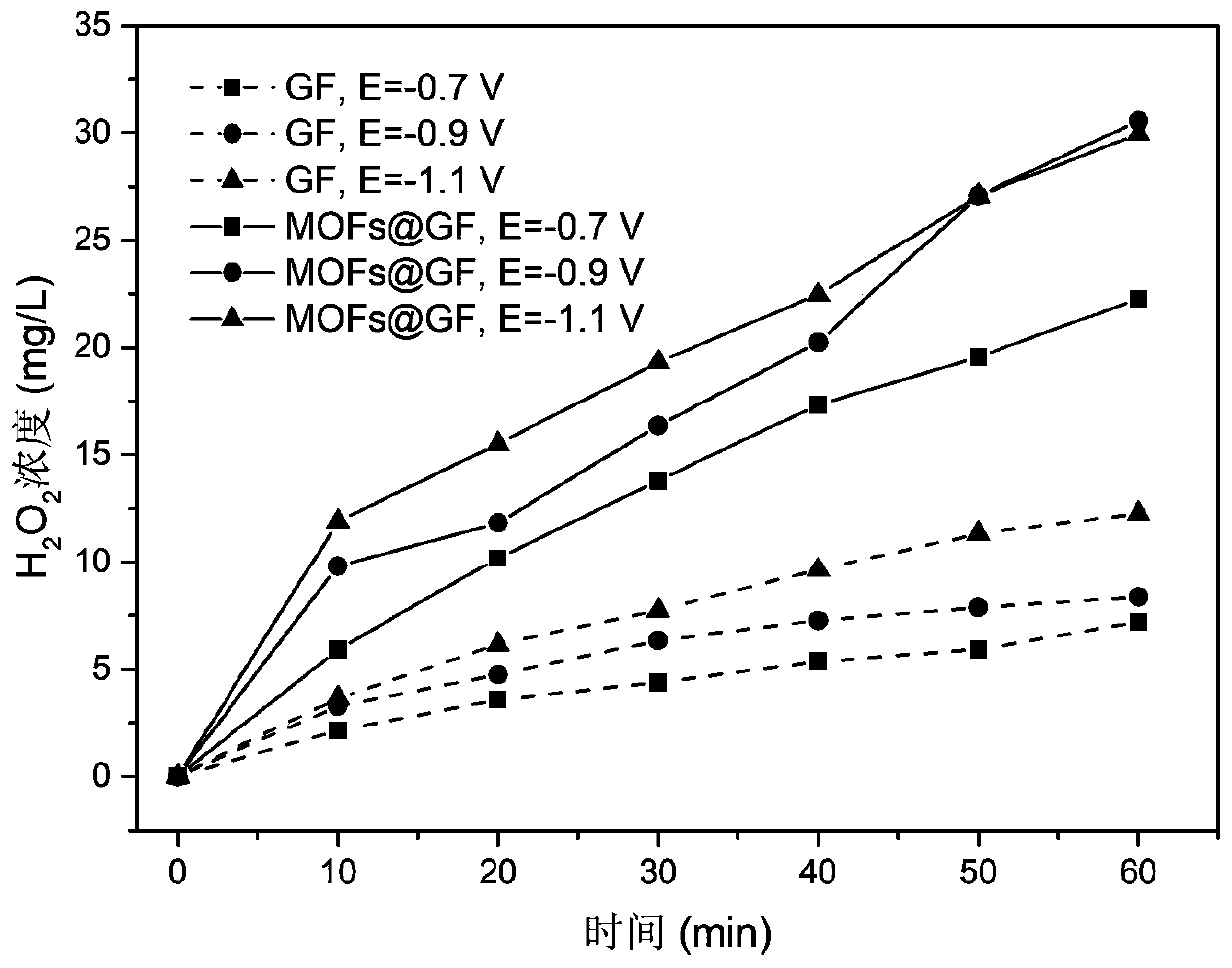

Embodiment 1

[0028] A preparation method of ink felt-supported metal organic framework compound cathode material provided in this example: 179mg FeCl 3 ·6H 2 O and 160mg of Pluronic F127 were dissolved in 15mL of deionized water, mixed and stirred for 1h to obtain a mixed solution. Add 0.3mL CH to the mixed solution 3 COOH and 60 mg of 2-aminoterephthalic acid were stirred for 4 hours to form a metal organic framework compound precursor solution. Cut commercial graphite felt with a thickness of 0.5 cm into a size of 3 cm × 2 cm, immerse in acetone and ultrasonically clean for 0.5 h to remove oil, and then rinse with ultrapure water to obtain a clean graphite felt GF. The metal-organic framework compound precursor solution and the graphite felt GF were placed in the reactor together, sealed and subjected to hydrothermal reaction at 110°C for 24h. After the reaction, the reactor was naturally cooled to room temperature, and the product was washed in ultrapure water at room temperature for...

Embodiment 2

[0033] A kind of preparation method of ink felt supported metal organic framework compound cathode material provided in this embodiment: 179mg Fe(NO 3 ) 3 9H 2 O and 160mg of Pluronic F127 were dissolved in 15mL of deionized water, mixed and stirred for 1.5h to obtain a mixed solution. Add 0.15mL formic acid and 60mg 2-aminoterephthalic acid into the mixed solution, stir for 2h, and configure the precursor solution of the metal organic framework compound. A commercial graphite felt with a thickness of 0.5 cm was cut into a size of 3 cm × 2 cm, immersed in acetone for 0.75 h to remove oil, and then rinsed with ultrapure water to obtain a clean graphite felt GF. The metal-organic framework compound precursor solution and the graphite felt GF were placed in the reactor together, sealed and subjected to hydrothermal reaction at 100°C for 36h. After the reaction, the reactor was naturally cooled to room temperature, and the product was washed in ultrapure water at room temperatu...

Embodiment 3

[0035] A method for preparing an ink felt-supported metal-organic framework compound cathode material provided in this example: 179mg Fe 2 (SO4) 3 9H 2 O and 320mg of Pluronic F127 were dissolved in 15mL of deionized water, mixed and stirred for 2h to obtain a mixed solution. Add 0.30 mL of formic acid and 60 mg of 2-aminoterephthalic acid into the mixed solution, stir for 3 hours, and configure the precursor solution of the metal organic framework compound. Cut a commercial graphite felt with a thickness of 0.5 cm into a size of 3 cm × 2 cm, immerse it in acetone and ultrasonically clean it for 1 hour to remove oil, and then rinse it with ultrapure water to obtain a clean graphite felt GF. The metal-organic framework compound precursor solution and the graphite felt GF were placed in the reaction kettle together, sealed and subjected to hydrothermal reaction at 130°C for 48h. After the reaction, the reactor was naturally cooled to room temperature, and the product was wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com