Membrane bioreactor

A membrane bioreactor and body technology, which is applied in the field of water treatment, can solve the problems of poor denitrification and phosphorus removal, serious membrane pollution, and short operation period, and achieve the effects of reducing operating costs, prolonging cleaning periods, and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

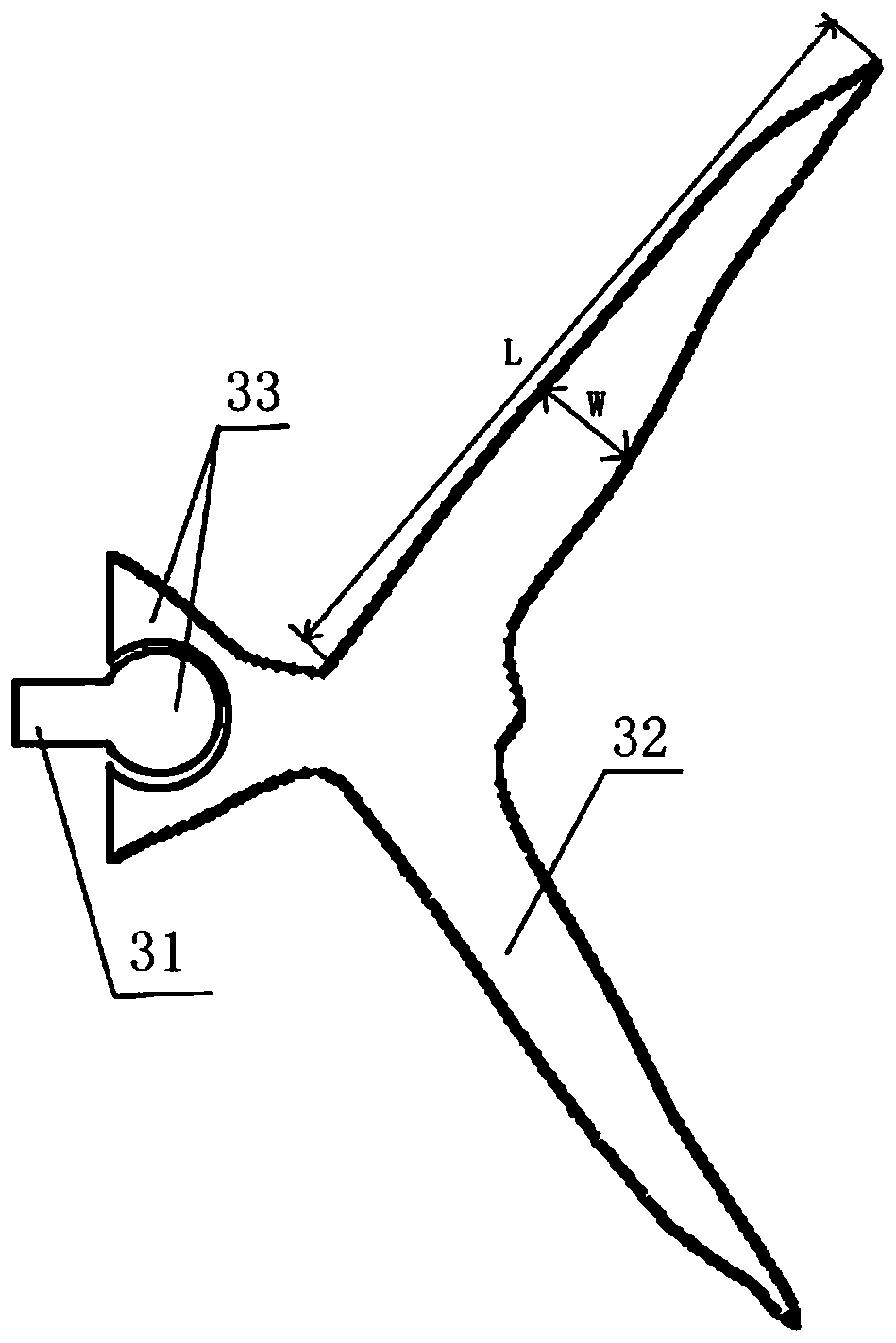

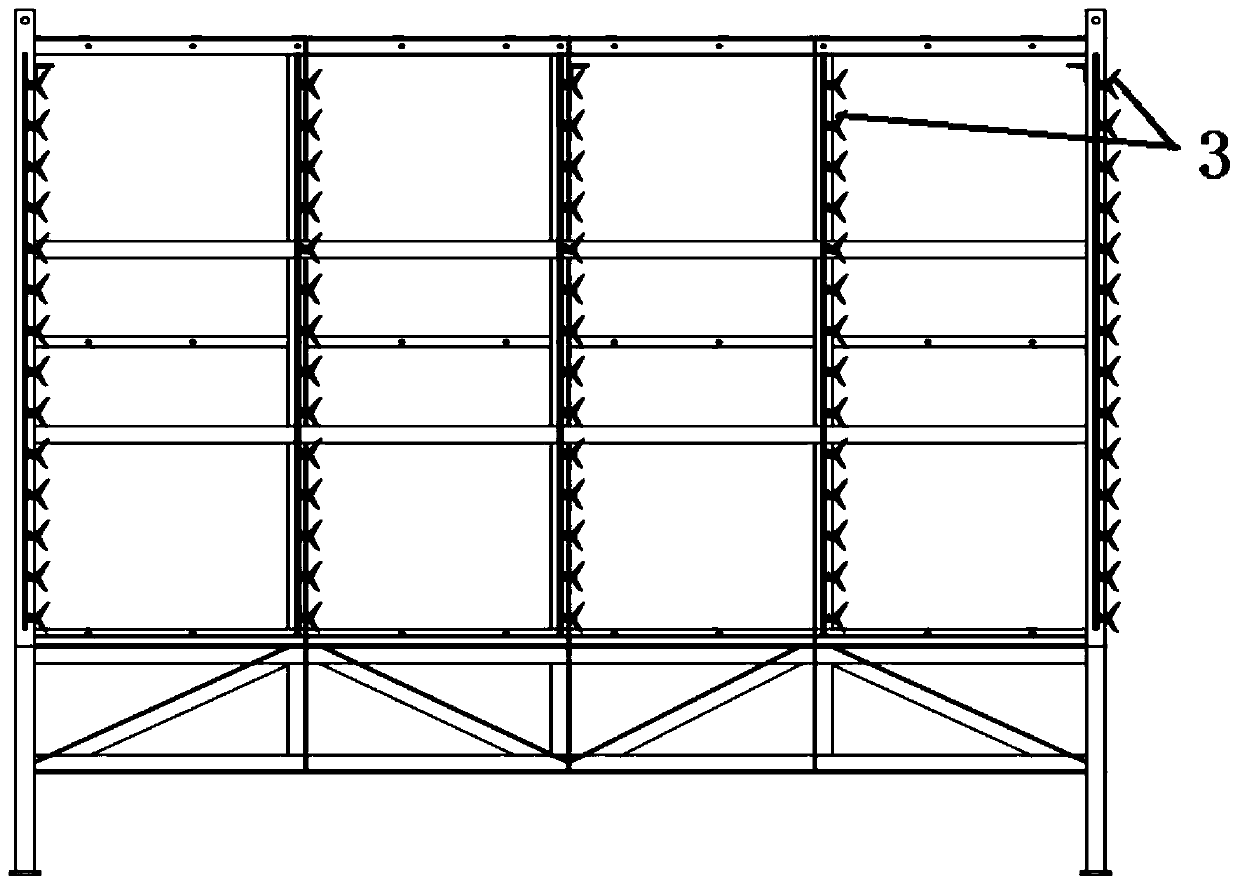

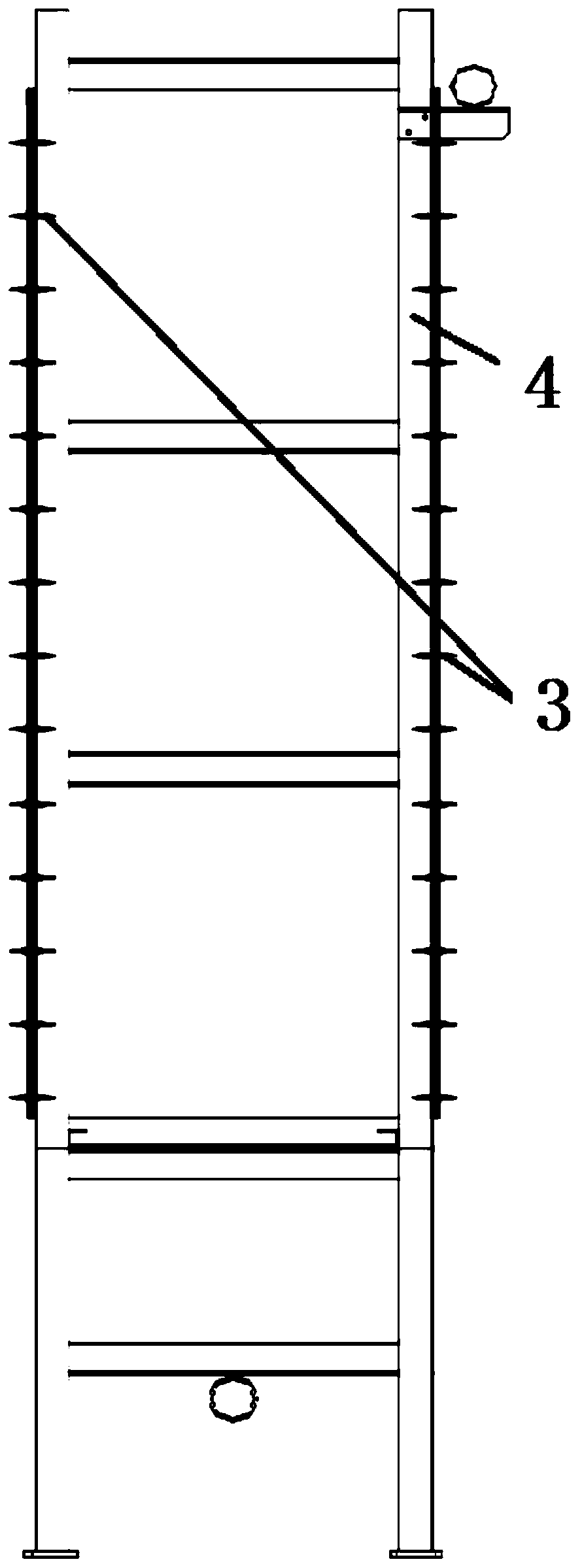

[0060] A membrane bioreactor, comprising a membrane bioreactor body, and several shuttlecock bodies 3 installed on the membrane bioreactor body, said shuttlecock body 3 comprising: a fixed shaft 31, a bristle body 32 and a rotating member 33, Such as Figure 1-Figure 3 shown. Wherein, the bristle body 32 is connected to the fixed shaft 31; the rotating member 33 is arranged on the fixed shaft 31 for making the bristle body 32 swing and rotate freely.

[0061]In the present invention, a shuttlecock body is added on the membrane bioreactor body, and the specific structure of the shuttlecock body is optimized. The shuttlecock body includes a fixed shaft, a bristle body and a rotating part; the rotating part is used to make the bristle body free Swing and rotation, that is, under the action of hydraulic impact or electric current, the bristle body realizes the functions of 360° rotation, stretching and shaking around the central axis. The size of the flying shuttlecock in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com