Carbon fiber reinforced weather-proof PC/ASA composite material and preparation method thereof

A composite material and carbon fiber technology, which is applied in the field of carbon fiber reinforced weather-resistant PC/ASA composite materials and its preparation, can solve the problems of low strength and poor wear resistance of ASA materials, increase service life and safety, improve comprehensive performance, and enhance rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

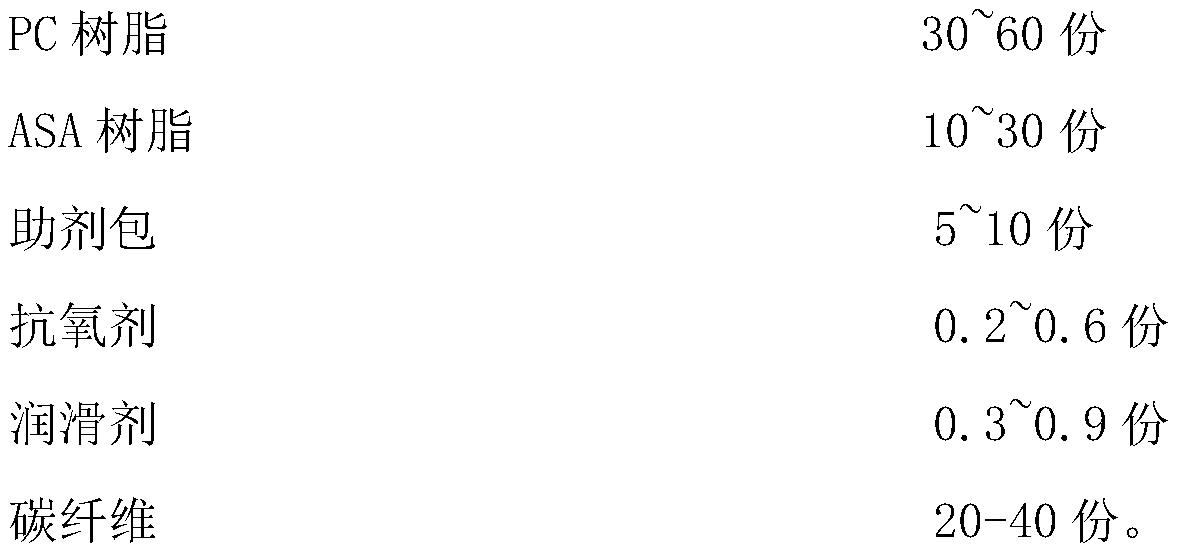

[0030] The invention also discloses a carbon fiber reinforced weather-resistant PC / ASA composite material and a preparation method thereof, comprising the following steps:

[0031] Step 1. Weigh each component in turn according to the above formula ratio, and stir the weighed components in a high-speed mixer for 3 to 5 minutes at a high speed to obtain a premix;

[0032] Step 2. Melt and extrude the premix obtained in Step 1 through a twin-screw extruder. At the same time, carbon fiber is added from the middle section of the screw by a side feeder. After water cooling, pelletizing, and mixing evenly, carbon fiber reinforced weather resistance is obtained. PC / ASA composite material;

[0033] Among them, the temperature setting of the twin-screw extruder is: ① area: 200-230 ° C; ② area: 210-240 ° C; ③ area: 220-250 ° C; ④ area: 220-250 ° C; ℃; ⑥ area: 205-240 ℃; ⑦ area: 200-240 ℃; ⑧ area: 220-250 ℃; ⑨ area head temperature: 220-250 ℃;

Embodiment 1

[0035] A carbon fiber reinforced weather-resistant PC / ASA composite material consists of the following components in parts by mass:

[0036]

[0037] The method for preparing the composite material of this embodiment comprises the following steps:

[0038] Step 1. Weigh each component in turn according to the above formula ratio, and stir the weighed components in a high-speed mixer for 3 to 5 minutes at a high speed to obtain a premix;

[0039] Step 2. Melt and extrude the premix obtained in Step 1 through a twin-screw extruder. At the same time, carbon fiber is added from the middle section of the screw by a side feeder. After water cooling, pelletizing, and mixing evenly, carbon fiber reinforced weather resistance is obtained. PC / ASA composite material;

[0040] Among them, the temperature setting of the twin-screw extruder is: ① area: 200-230 ° C; ② area: 210-240 ° C; ③ area: 220-250 ° C; ④ area: 220-250 ° C; ℃; ⑥ area: 205-240 ℃; ⑦ area: 200-240 ℃; ⑧ area: 220-250 ℃;...

Embodiment 2

[0043] A carbon fiber reinforced weather-resistant PC / ASA composite material consists of the following components in parts by mass:

[0044]

[0045] The method for preparing the composite material of this embodiment comprises the following steps:

[0046] Step 1. Weigh each component in turn according to the above formula ratio, and stir the weighed components in a high-speed mixer for 3 to 5 minutes at a high speed to obtain a premix;

[0047] Step 2. Melt and extrude the premix obtained in Step 1 through a twin-screw extruder. At the same time, carbon fiber is added from the middle section of the screw by a side feeder. After water cooling, pelletizing, and mixing evenly, carbon fiber reinforced weather resistance is obtained. PC / ASA composite material;

[0048] Among them, the temperature setting of the twin-screw extruder is: ① area: 200-230 ° C; ② area: 210-240 ° C; ③ area: 220-250 ° C; ④ area: 220-250 ° C; ℃; ⑥ area: 205-240 ℃; ⑦ area: 200-240 ℃; ⑧ area: 220-250 ℃;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com