A kind of reflective hot-melt marking paint and construction method thereof

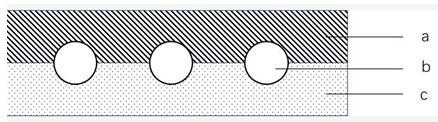

A marking paint and reflective technology, applied in the direction of reflection/signal paint, polyether paint, polyester paint, etc., can solve the problems of poor reflection of embedded glass beads, poor wear resistance of marking paint, and easy falling off of glass beads. , to achieve the effect of tight bonding, enhanced reflectivity, high brightness and durable wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

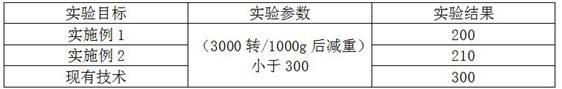

Embodiment 1

[0030] Prepare ingredients:

[0031] Surface layer raw materials: 5 parts of hydroxymethyl cellulose, 5 parts of nitrocellulose, 12 parts of acrylic resin, 8 parts of ethyl cellosolve acetate, 0.8 parts of polyethylene wax; put the above materials into a hot melting furnace, 180 melts at 100 degrees Celsius,

[0032] Bottom layer raw materials: 13 parts of titanium dioxide, 12 parts of petroleum resin, 1.5 parts of plasticizer, 1.4 parts of EVA, 8 parts of PLA-PEG, 3 parts of flake alumina; after mixing the above raw materials evenly, add them to the melting furnace, 220 Melt at Celsius;

[0033] 15 parts of glass beads: the particle size is 30-60 mesh, and the roundness rate is greater than 70%.

[0034] Specific construction:

[0035] Clean the pavement, keep it free of litter, and use a primer to level the pavement so it's smooth and pothole-free. Draw construction lines.

[0036] Draw the hot-melt bottom layer material along the construction line with a thickness of a...

Embodiment 2

[0040] Prepare raw materials

[0041] Surface layer raw materials: 6 parts of hydroxymethyl cellulose, 6 parts of nitrocellulose, 15 parts of acrylic resin, 10 parts of ethyl cellosolve acetate, 1 part of polyethylene wax; put the above raw materials into a hot melting furnace, 180 melts at 100 degrees Celsius,

[0042] Bottom layer raw materials: 15 parts of titanium dioxide, 20 parts of petroleum resin, 1.5 parts of plasticizer, 1.5 parts of EVA, 8 parts of PLA-PEG, 3 parts of flaky alumina; after mixing the above raw materials evenly, add them to the melting furnace, 220 Melt at Celsius;

[0043] 10 parts of glass beads: the particle size is 30-60 mesh, and the roundness rate is greater than 70%.

[0044] Specific construction:

[0045] Clean the pavement, keep it free of litter, and use a primer to level the pavement so it's smooth and pothole-free. Draw construction lines.

[0046] Draw the hot-melt bottom layer material along the construction line with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com