Dust collection equipment for textile printing and dyeing and dust collection method of dust collection equipment

A technology for textile printing and dyeing and equipment, which is applied in the field of vacuuming equipment for textile printing and dyeing and its dust collection, can solve the problems of dust and organic gas leakage, damage to the lungs of surrounding workers, and dust and organic gas cannot be completely pumped upwards. Achieve the effect of reducing power loss and protecting the cyclone separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

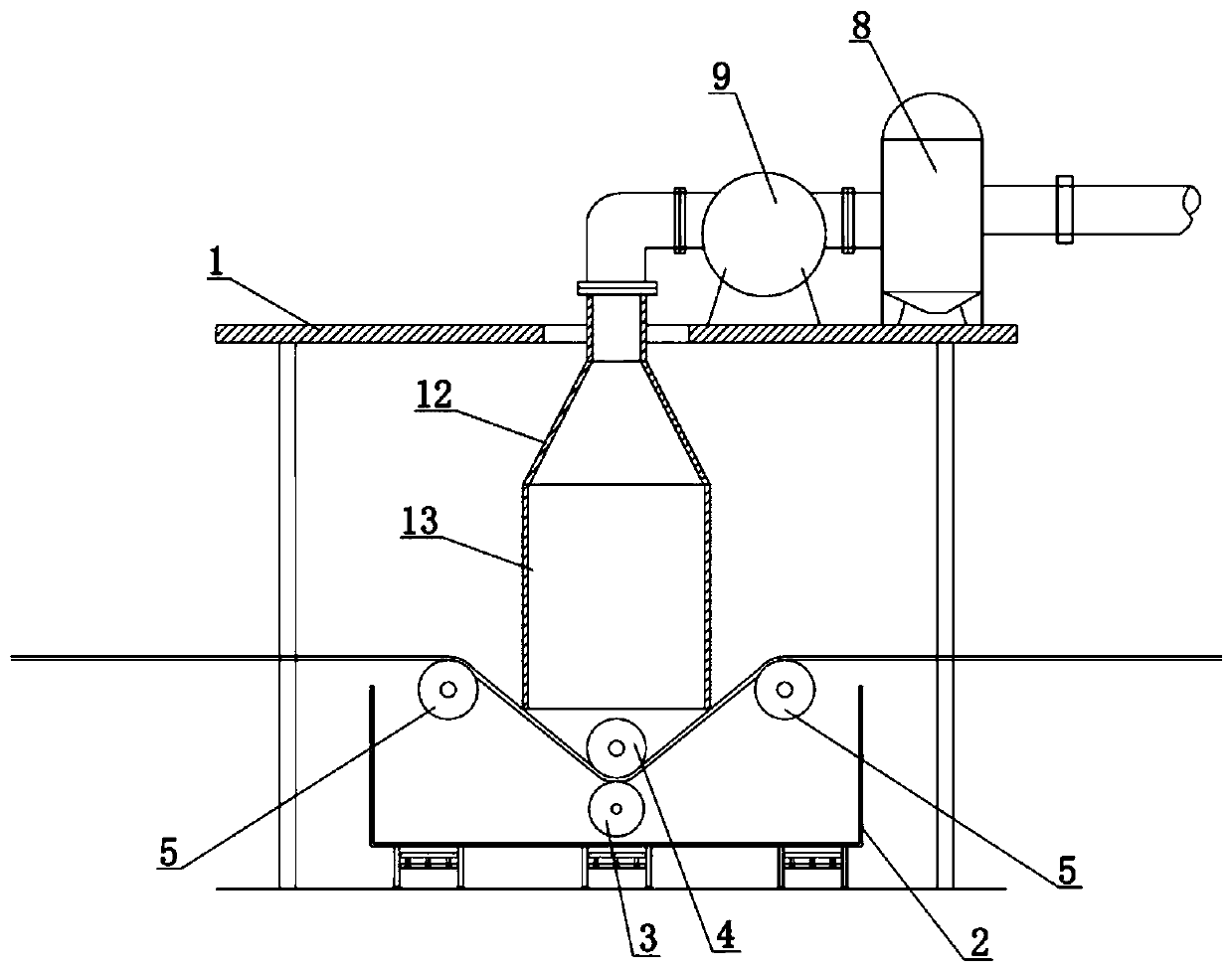

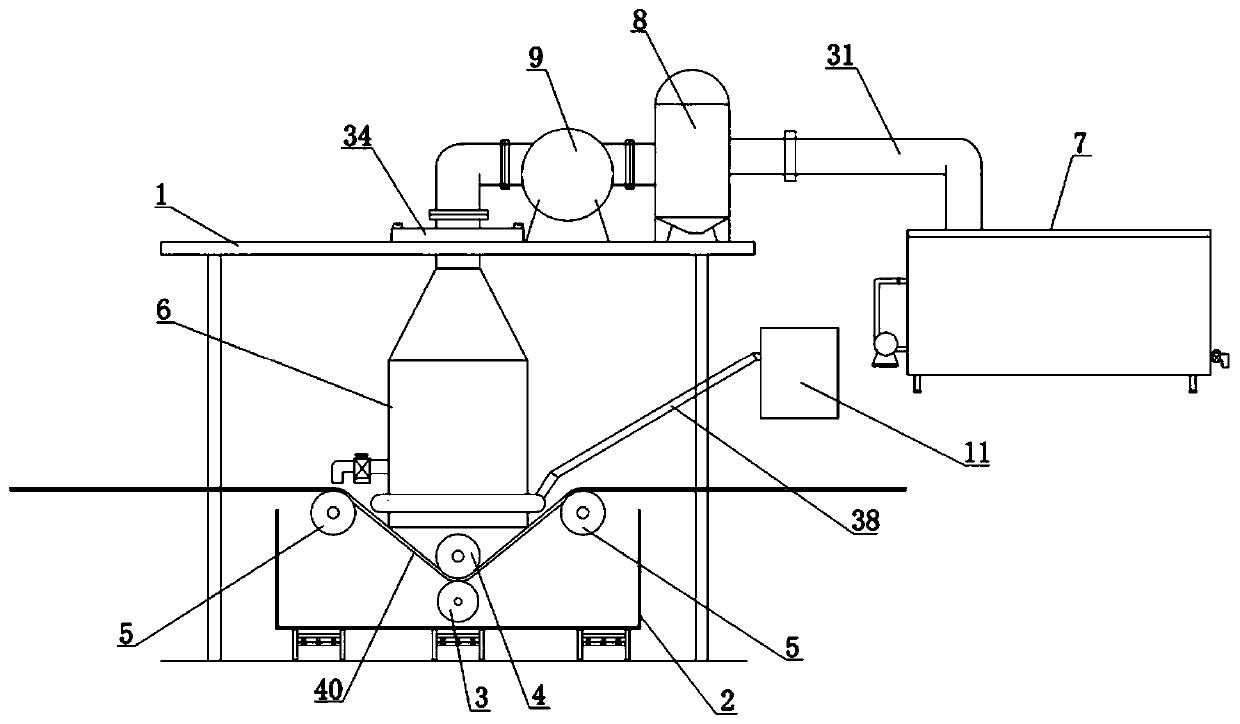

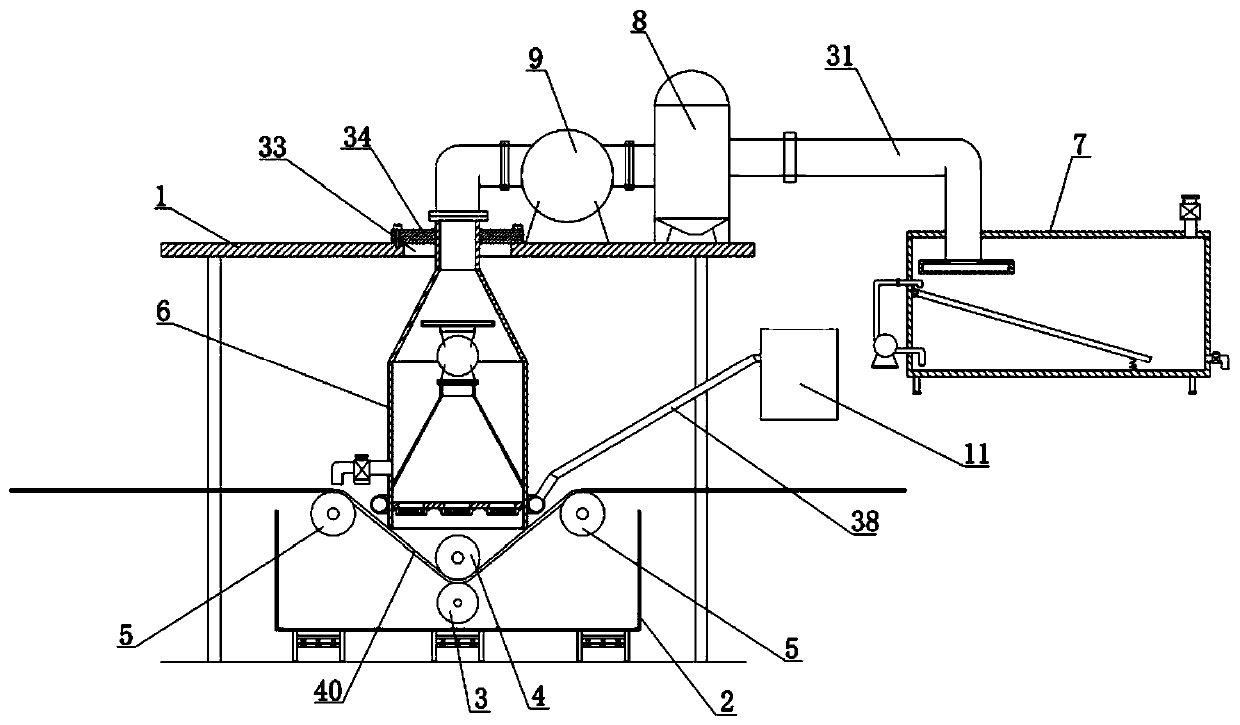

[0040] Embodiment one: if Figure 2-9 As shown, a kind of vacuuming equipment for textile printing and dyeing, which includes a gantry 1, a printing and dyeing box 2 arranged under the beam of the gantry 1, and a pressure wheel 3 and a printing and dyeing wheel 4 are installed in the printing and dyeing box 2, and the printing and dyeing wheel 4 Located directly above the pressing wheel 3, the printing and dyeing wheel 4 is tangent to the pressing wheel 3. The printing and dyeing box 2 is also rotatably installed with guide wheels 5 located on the left and right sides of the printing and dyeing wheel 4. It is characterized in that it also includes a dust collection device 6, organic gas The absorption device 7, the cyclone separator 8 and the fan A9 fixed on the top of the crossbeam, the dust suction device 6 includes a dust suction tube, an annular pipe 10 and an air compressor 11, and the dust suction tube is arranged at the lateral bottom of the gantry frame 1, and the sucti...

Embodiment 2

[0050] Embodiment two: if Figure 10 As shown, a kind of vacuuming equipment for textile printing and dyeing, the difference between this embodiment and the second embodiment is that it also includes a controller 39, and the controller 39 is arranged on the column of the gantry 1, and the controller 39 It is electrically connected with stop valve 37, liquid outlet valve 29, replenishment valve 35, fan A9, exhaust fan 17, and fan B18. It can control the start or stop of fan A9, exhaust fan 17 and fan B18, which facilitates the operation of the work and has the characteristics of high degree of automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com