Photovoltaic module adhesive film printed with latticed white ink on surface

A white ink, photovoltaic module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of reducing reflectivity, affecting power generation efficiency, and low gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

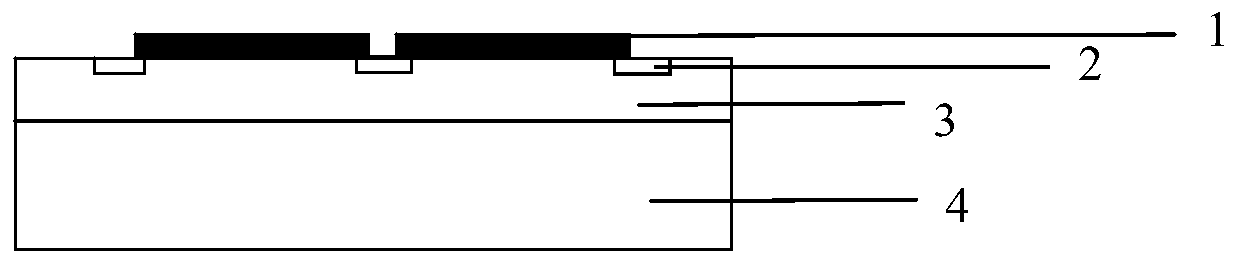

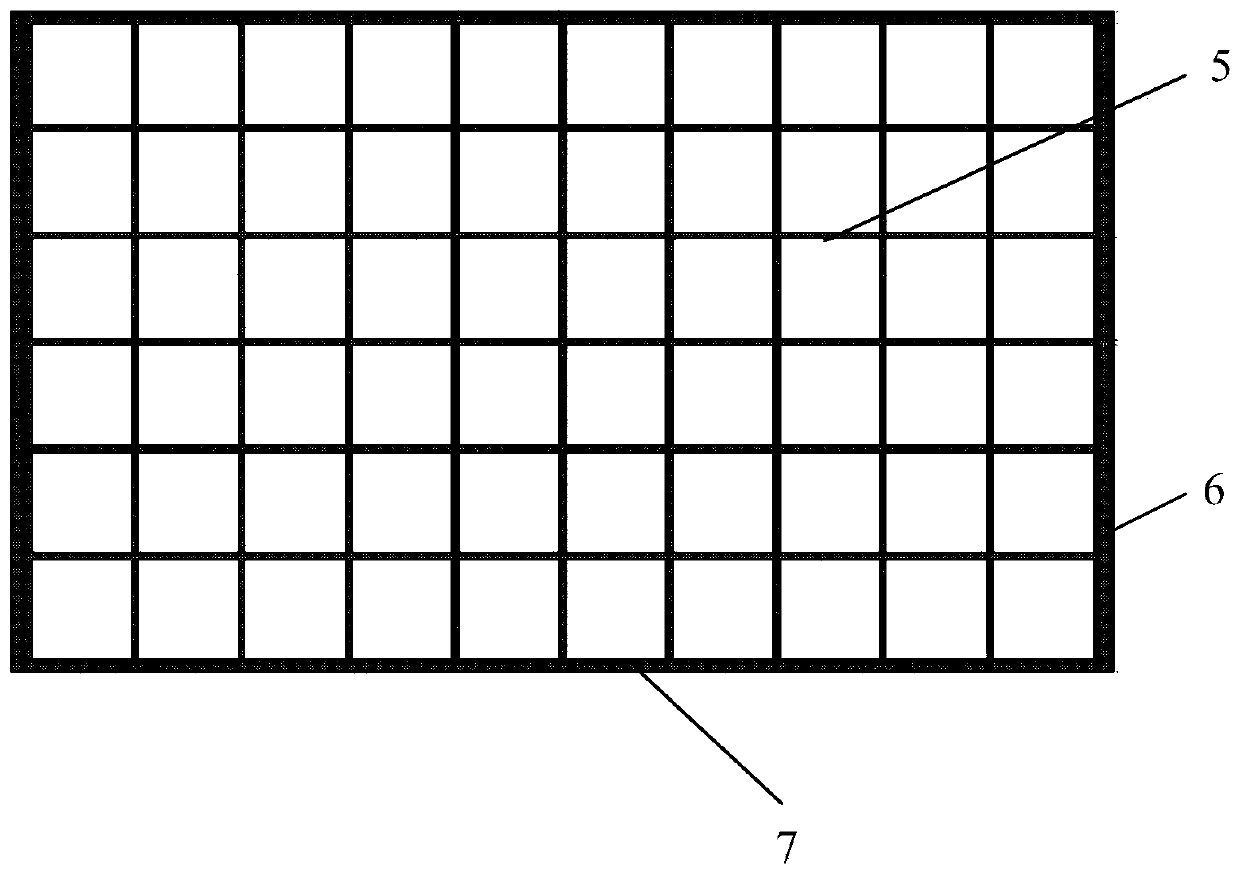

[0027] Print a layer B with a thickness of 5 μm on the surface of layer A composed of EVA / POE double-layer co-extrusion film, and the thickness of layer A is 400 μm. Use a vulcanization meter (UKEN Technology Co., Ltd. V9.50MDR type) to test the film at 140 °C The ML value is 0.15N·m, the width of each central grid line of the layer B grid is 2.1cm, the width of the grid used for the short edge of the component is 16mm, and the width of the grid used for the long edge of the component is 12mm. Cut the adhesive film to the size of the solar photovoltaic module, and stack it in the order of glass / common transparent EVA adhesive film / battery sheet / photovoltaic module adhesive film / glass with grid-shaped white ink printed on the surface, and combine this structure and After the comparison module using ordinary transparent EVA film on the upper and lower layers is laminated at 145°C, the module power of this structure is 2% higher than that of the comparison module.

Embodiment 2

[0029] Print layer B with a thickness of 20 μm on the surface of layer A composed of EVA / POE / EVA three-layer co-extrusion film, the thickness of layer A is 600 μm, and use a vulcanization meter (Youcan Technology Co., Ltd. V9.50MDR type) to test the glue at 140 ° C The ML value of the film is 0.3N·m, the width of each central grid line of the layer B grid is 9cm, the width of the grid used for the short edge of the module is 40mm, and the width of the grid used for the long edge of the module is 20mm. Cut the adhesive film to the size of the solar photovoltaic module, and stack it in the order of glass / common transparent EVA adhesive film / battery sheet / photovoltaic module adhesive film / glass with grid-shaped white ink printed on the surface, and combine this structure and After the comparison module using ordinary transparent EVA film on the upper and lower layers is laminated at 145°C, the module power of this structure is 1.5% higher than that of the comparison module.

Embodiment 3

[0031] Print 80 μm thick layer B on the surface of layer A composed of EVA / POE / EVA / POE four-layer co-extrusion film, the thickness of layer A is 200 μm, and test it with a vulcanization meter (UKEN Technology Co., Ltd. V9.50MDR type) at 140 ° C The ML value of the lower adhesive film is 0.25N m, the width of each central grid line of the layer B grid is 3cm, the width of the grid used for the short edge of the component is 16.75mm, and the width of the grid used for the long edge of the component is 22mm. Cut the adhesive film to the size of the solar photovoltaic module, and stack it in the order of glass / common transparent EVA adhesive film / battery sheet / photovoltaic module adhesive film / glass with grid-shaped white ink printed on the surface, and combine this structure and After the comparison module using ordinary transparent EVA film on the upper and lower layers is laminated at 145°C, the module power of this structure is 5% higher than that of the comparison module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com