3D catalyst for catalytic degradation of organic pollutants as well as preparation and application of 3D catalyst

A technology for the catalytic degradation of organic pollutants, applied in the field of biocatalysts, can solve the problems of large corrosion of 3D catalysts, easy loss of supported ions, and excessive performance degradation, so as to improve the loading effect, enrich active groups, and improve catalytic degradation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Cotton crop stalk (cotton stalk) is dried at 80 ℃, pulverizes, screens out 200 mesh particles with sieve, is 1g:10ml solid-liquid ratio according to solid-liquid ratio 5g biomass and 50ml 50% citric acid solution are added to Then add 5% (based on biomass weight) Co(NO 3 ) 2 or CoCl 2 After stirring evenly, let it stand for 20mins to carry out structural penetration. Put the open reaction vessel into an oven and burn it at 200°C for 3h. Use distilled water to ultrasonically wash away impurities for about 20mins. Distilled water is filtered and washed until neutral, and then dried. After adding pesticides to the prepared product, mix and shake with PMS or PDS, and finally measure the degradation rate of pesticides, which is recorded as sample 1;

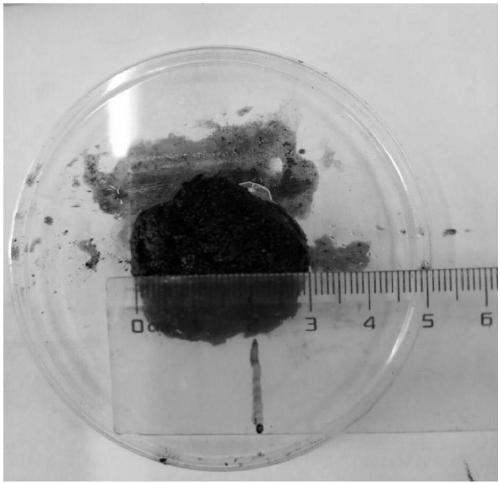

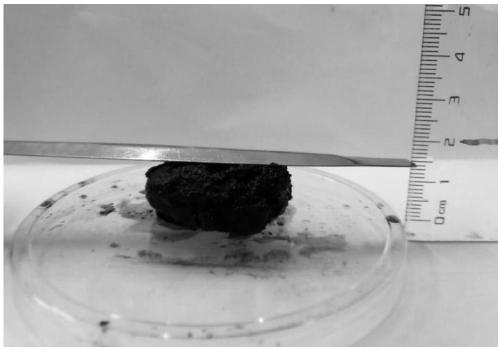

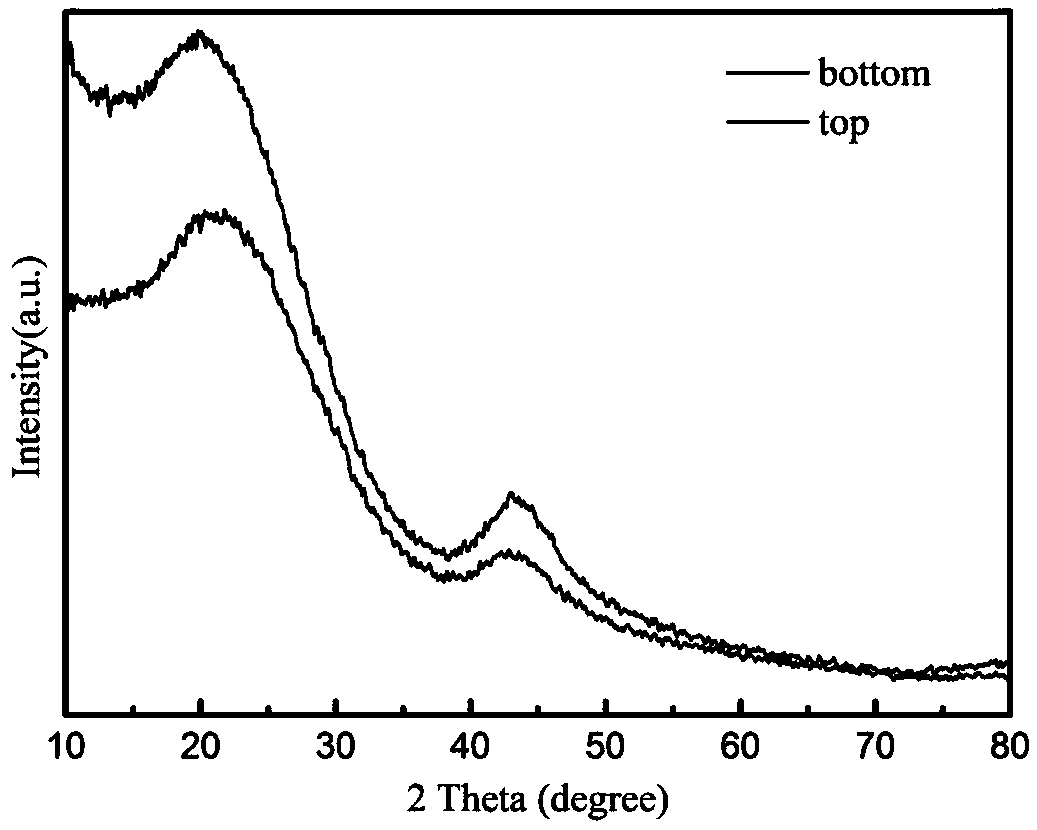

[0085]The 3DSEM image of sample 1 biochar is shown in 4, showing an amorphous structure. front view see figure 1 ; top view see figure 2 .

Embodiment 2

[0087] Compared with Example 1, the difference is that phosphoric acid is used to replace citric acid, specifically as follows:

[0088] Dry the cotton crop stalks at 80°C, crush them, and screen out 200-mesh particles with a sieve, and add 5g of biomass and 50ml of 50% phosphoric acid solution to the open reaction vessel according to the solid-to-liquid ratio of 1g:10ml Add 5% (based on biomass weight) Co(NO 3 ) 2 or CoCl 2 Solution, stir evenly, let it stand for 20mins to carry out structure penetration, put the reaction vessel in an oven and burn it at 200°C for 3h, use distilled water to ultrasonically wash away impurities for about 20mins, filter and wash with distilled water until it is neutral, and then dry it to obtain the product. Add pesticides After mixing and shaking with PMS or PDS, the final pesticide

[0089] Degradation rate, recorded as sample two;

[0090] Sample 2 biochar 3D image see Figure 5 . The carbon material has a granular amorphous structure. ...

Embodiment 3

[0092] Compared with Example 2, the difference is that 85% phosphoric acid is used to replace 50% phosphoric acid, specifically as follows:

[0093] Dry the cotton crop stalks at 80°C, crush them, and screen out 200-mesh particles with a sieve. Add 5g of biomass and 50ml of 85% phosphoric acid solution to the open reaction vessel according to the solid-to-liquid ratio of 1g:10ml. Add 5% (based on biomass weight) Co(NO 3 ) 2 or CoCl 2 Solution, stir evenly, let it stand for 20mins to carry out structure penetration, put the reaction vessel in an oven and burn it at 200°C for 3h, use distilled water to ultrasonically wash away impurities for about 20mins, filter and wash with distilled water until it is neutral, and then dry it to obtain the product. Add pesticides After mixing and shaking with PMS or PDS, the final degradation rate of the pesticide is recorded as sample three;

[0094] See 6 for the SEM image of sample three biochar. The carbon material has a granular amorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com