Lead plate manufacturing device used in cooperation with lead melting pool

A technology for manufacturing devices and lead plates, which is applied in the direction of manufacturing tools, casting workshops, casting equipment, etc., can solve the problems of tedious, time-consuming, time-consuming and labor-intensive, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

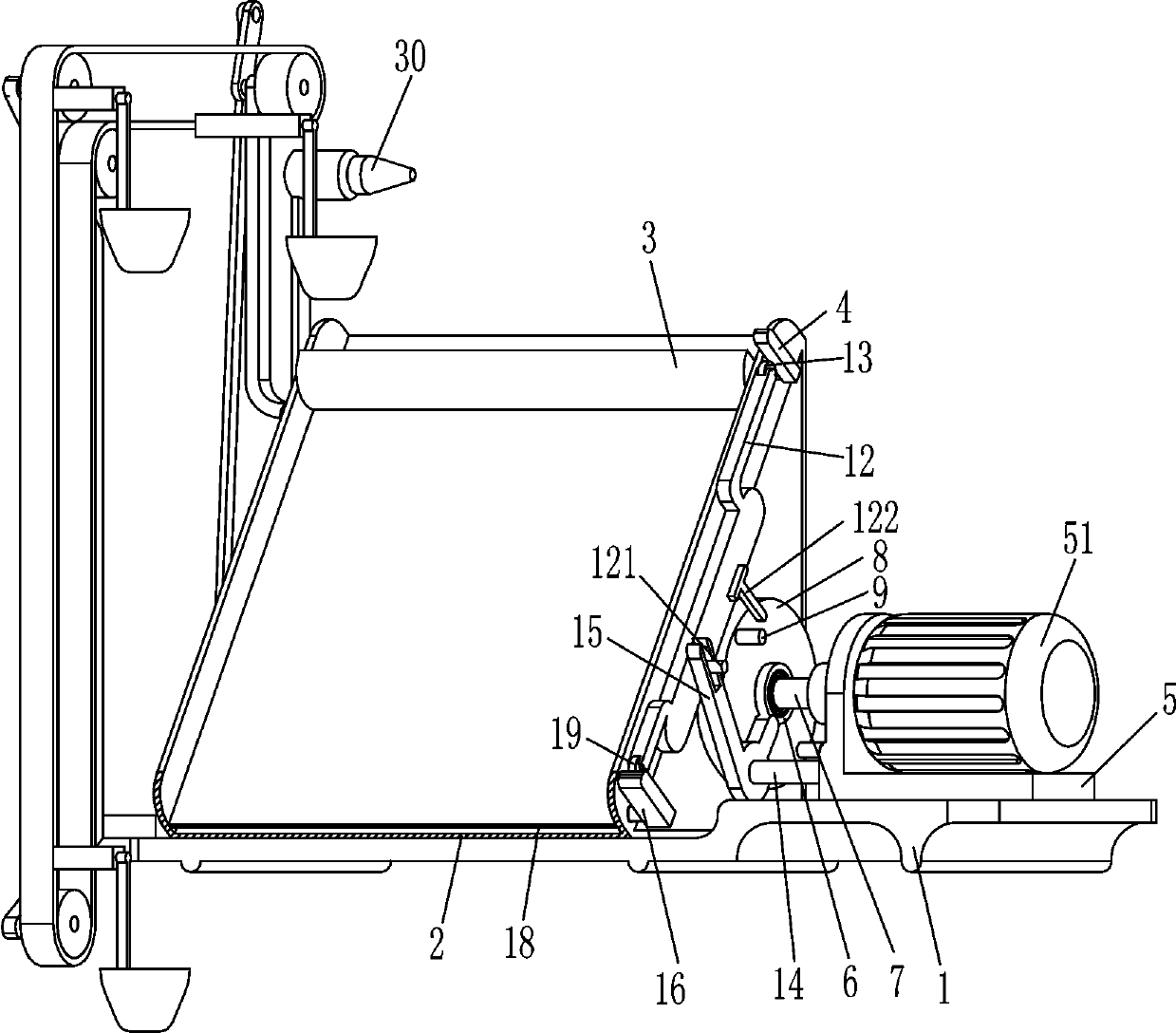

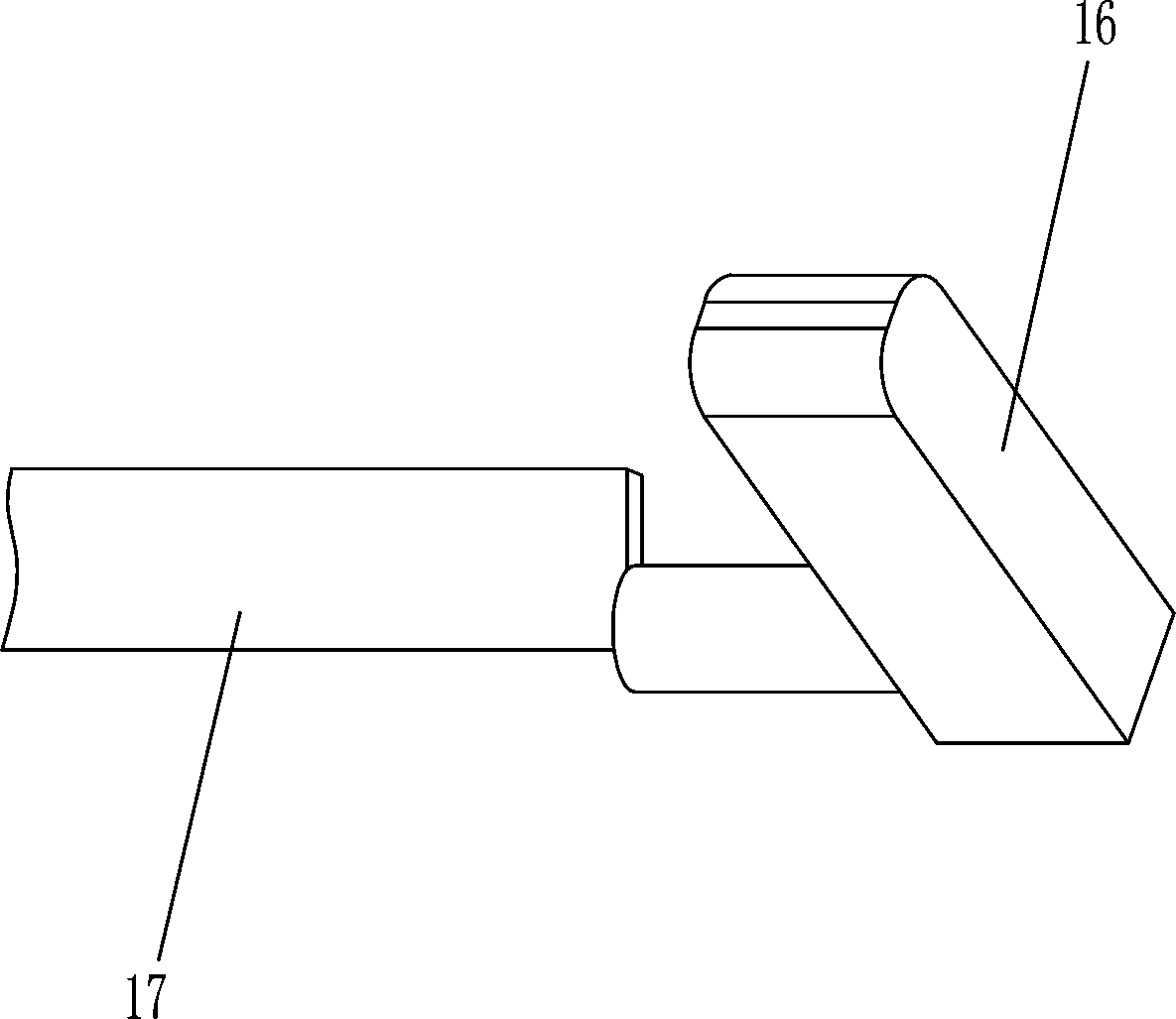

[0021] A lead plate making device used in conjunction with a lead melting pool, such as Figure 1-5 As shown, it includes a base 1, a support base 101, a forming bucket 2, a hopper 3, a first swinging member 4, a mounting base 5, a motor 51, a bearing 6, a shaft rod 7, an internal gear plate 8, and a first spur gear 801 , second spur gear 802, toggle column 9, slide rail 10, slider 11, toggle plate 12, toggle slide column 121, T-shaped plate 122, first roller 13, rotating shaft 14, L-shaped dial 15 and Separation device, the support seat 101 is fixedly connected to the rear side of the left part of the base 1, the forming bucket 2 is fixedly connected to the upper middle part of the base 1, and the upper part of the forming bucket 2 is rotatably connected to the uniform hopper 3, which is installed in parallel with the base 1 , the right end of the uniform hopper 3 is equipped with a first swinging member 4, the upper right side platform of the base 1 is fixedly connected with...

Embodiment 2

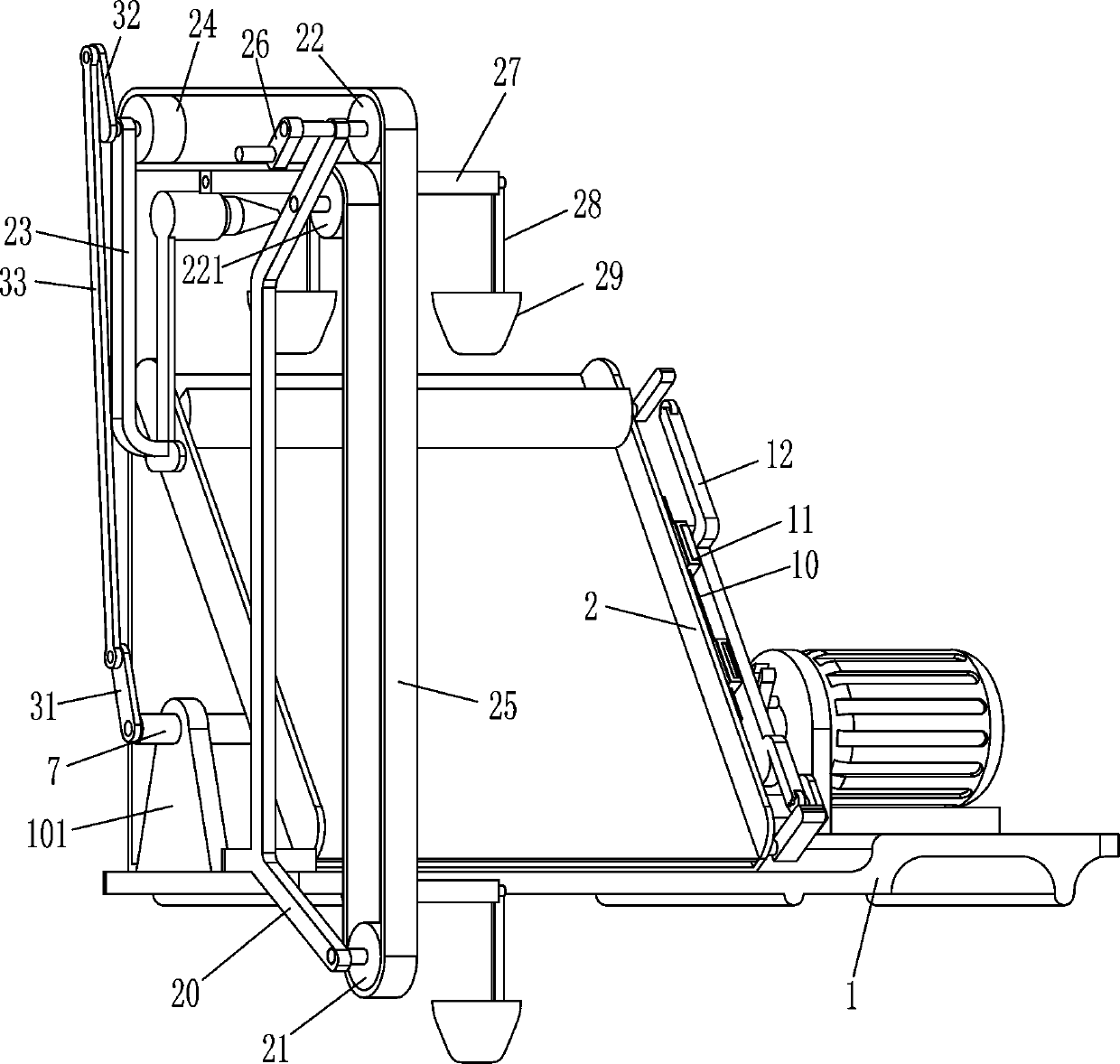

[0026] On the basis of Example 1, such as Figure 1-3Shown, also include the first support 20, the first synchronous pulley 21, the second synchronous pulley 22, the 4th synchronous pulley 221, the second support 23, the 3rd synchronous pulley 24, synchronous belt 25, rocking handle 26. Mounting block 27, connecting rod 28 and spoon 29, the upper left side of the base 1 is fixedly connected with the first support 20, the lower end of the first support 20 is rotatably connected with the first synchronous pulley 21, and the upper end of the first support 20 is rotatably connected There is a second synchronous pulley 22, and one end of the rocking handle 26 is fixedly connected on the rotating shaft of the second synchronous pulley 22, and a fourth synchronous pulley 221 is installed on the outside of the first bracket 20 top, and the fourth synchronous pulley 221 is located at the second Below the synchronous belt pulley 22, the second support 23 is installed on the top of the l...

Embodiment 3

[0029] On the basis of Example 2, such as Image 6 As shown, it also includes a spoon dial device 30. The spoon dial device 30 includes a third bracket 301, an outer jacket 302, a guide block 303, a tapered block 304 and a spring 305, and the outer wall on the left side of the forming bucket 2 is fixedly equipped with a third bracket 301. , the upper end of the third bracket 301 is fixedly connected with a jacket 302, the inside of the jacket 302 is movably connected with a guide block 303, the guide block 303 can slide inside the jacket 302, and the outside of the guide block 303 is fixedly connected with a tapered block 304, the tapered block 304 The end of the outer cover 302 can slide on the left side, the inner side of the guide block 303 is equipped with a spring 305, and the other end of the spring 305 is fixedly connected on the inner left side wall of the outer cover 302.

[0030] When the mounting block 27 moves to the top of the uniform hopper 3, the mounting block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com