Dry-mixed mortar gravel raw material treatment device

A technology for raw material processing and dry-mixing mortar, which is applied in heating devices, drying machines, dryers, etc., can solve the problems of agglomeration of sand and gravel raw materials, reduce the screening effect, and reduce the screening accuracy, so as to increase the heating time, prolong the The effect of moving paths, improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

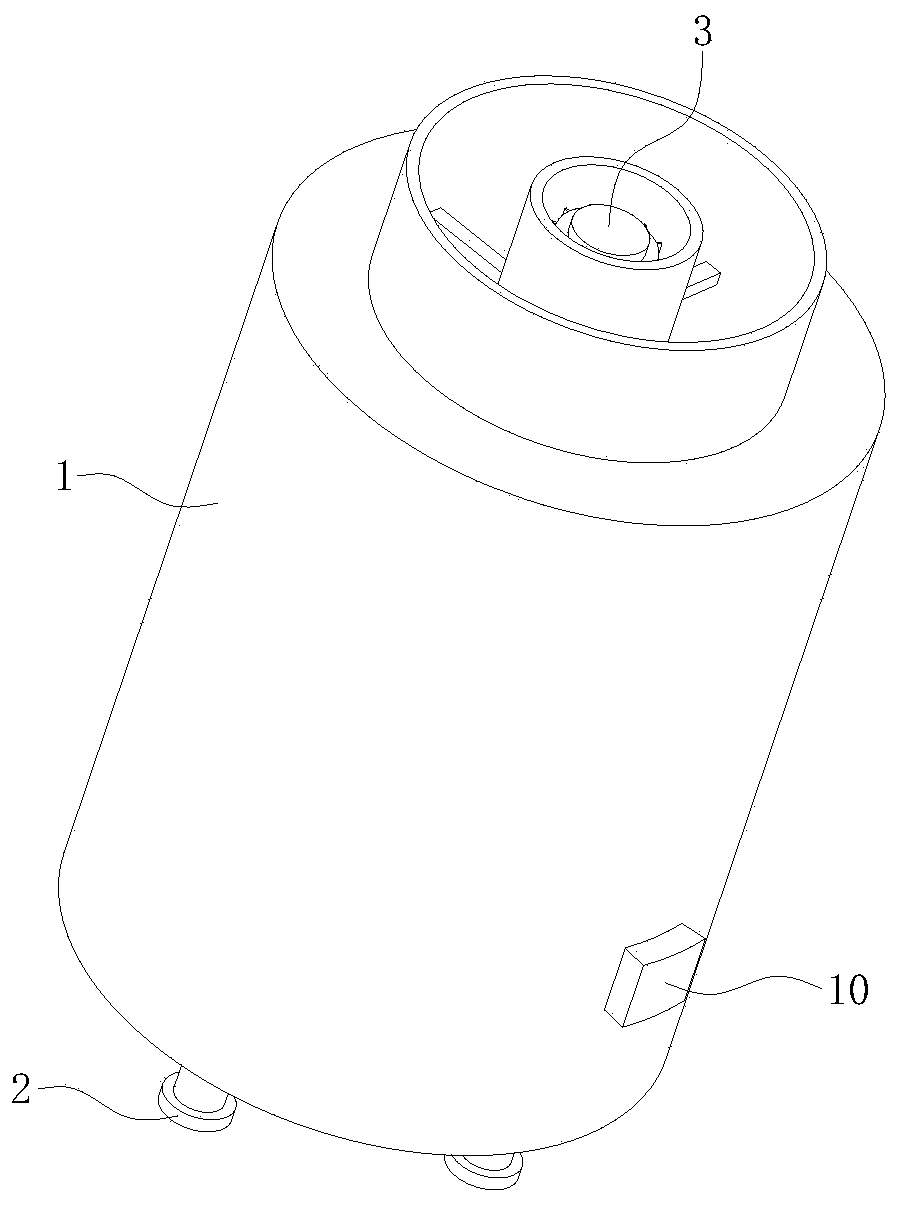

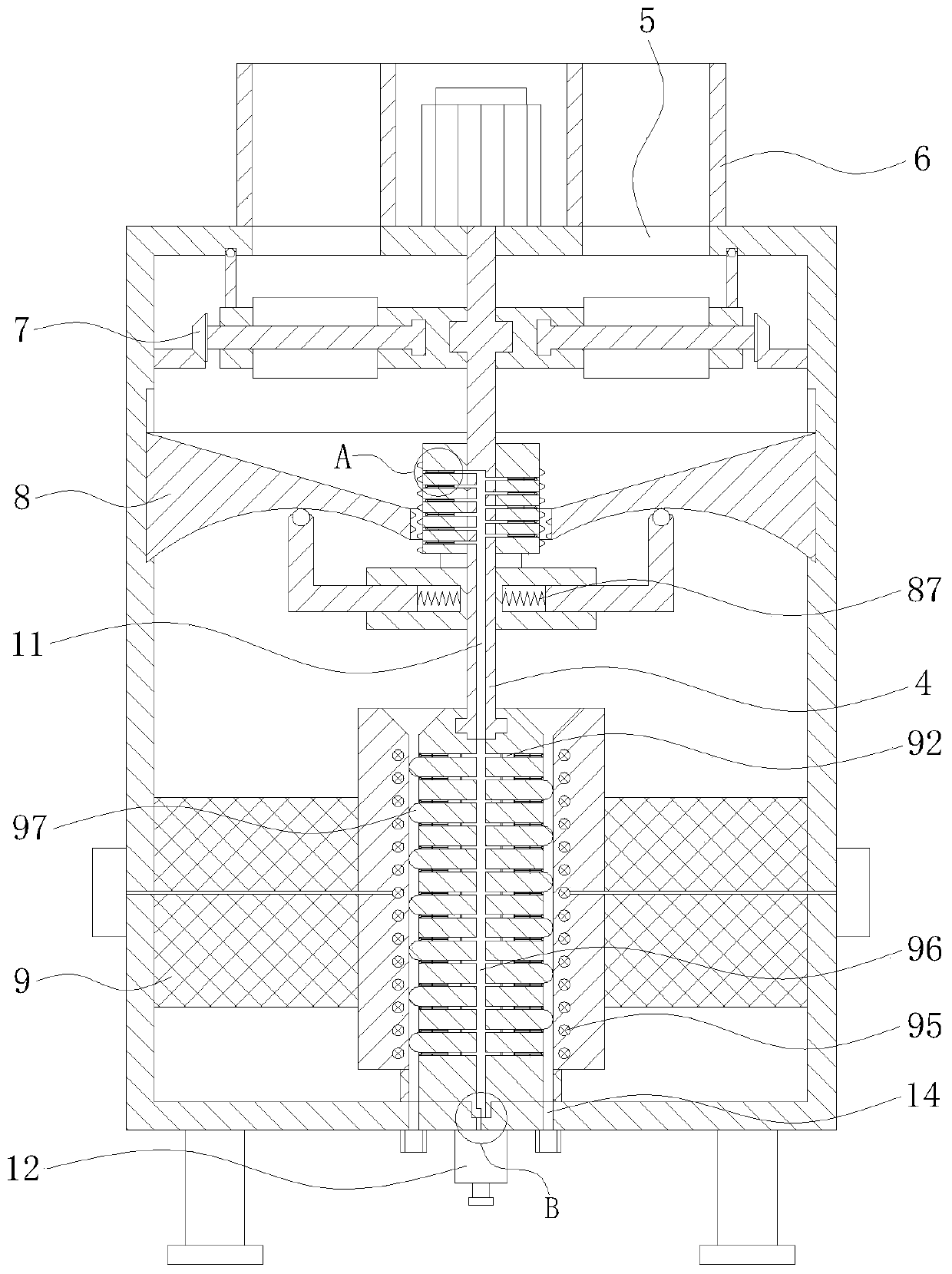

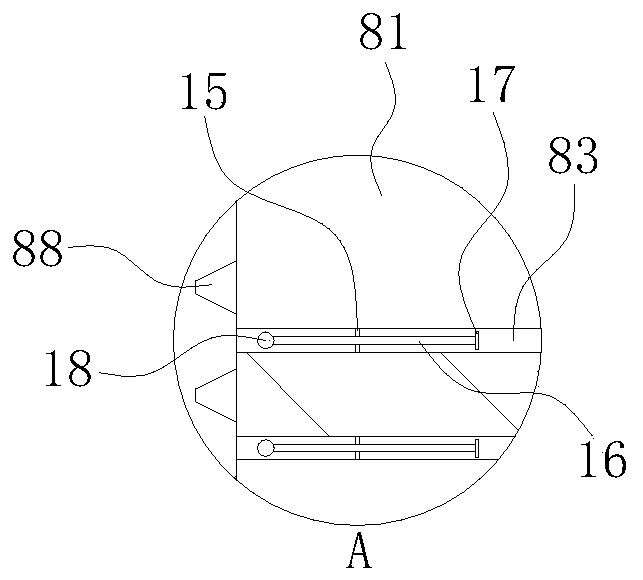

[0033] Such as Figure 1 to Figure 8 As shown, this embodiment provides a dry-mixed mortar sandstone raw material processing device for drying sandstone raw materials, including a cylindrical sealing cylinder 1, and a support leg 2 is vertically and fixedly installed under the bottom plate of the sealing cylinder 1. A rotary motor 3 is vertically fixedly installed on the top plate of the sealing cylinder 1 through a motor base, and the output shaft 4 of the rotary motor 3 penetrates the top plate of the sealing cylinder 1 and extends into the inside of the sealing cylinder 1 . An annular feeding port 5 is opened around the motor 3 on the top plate of the sealing cylinder 1 , and an annular first material baffle plate 6 is installed on the edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com