Silicon rod squaring and polishing integrated machine

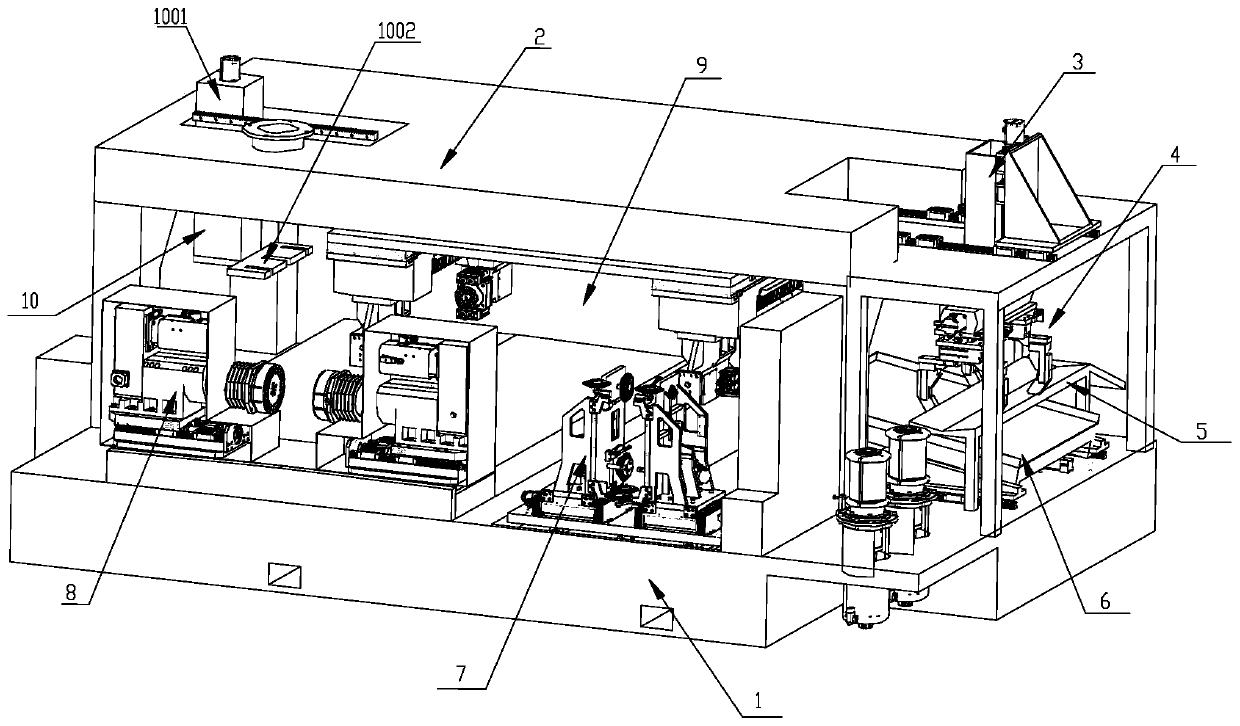

An all-in-one machine and silicon rod technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of increasing silicon rod grinding allowance and space Mutual interference, prolonging the processing time of silicon rods and other issues, to achieve the effect of improving transfer efficiency, improving work efficiency and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

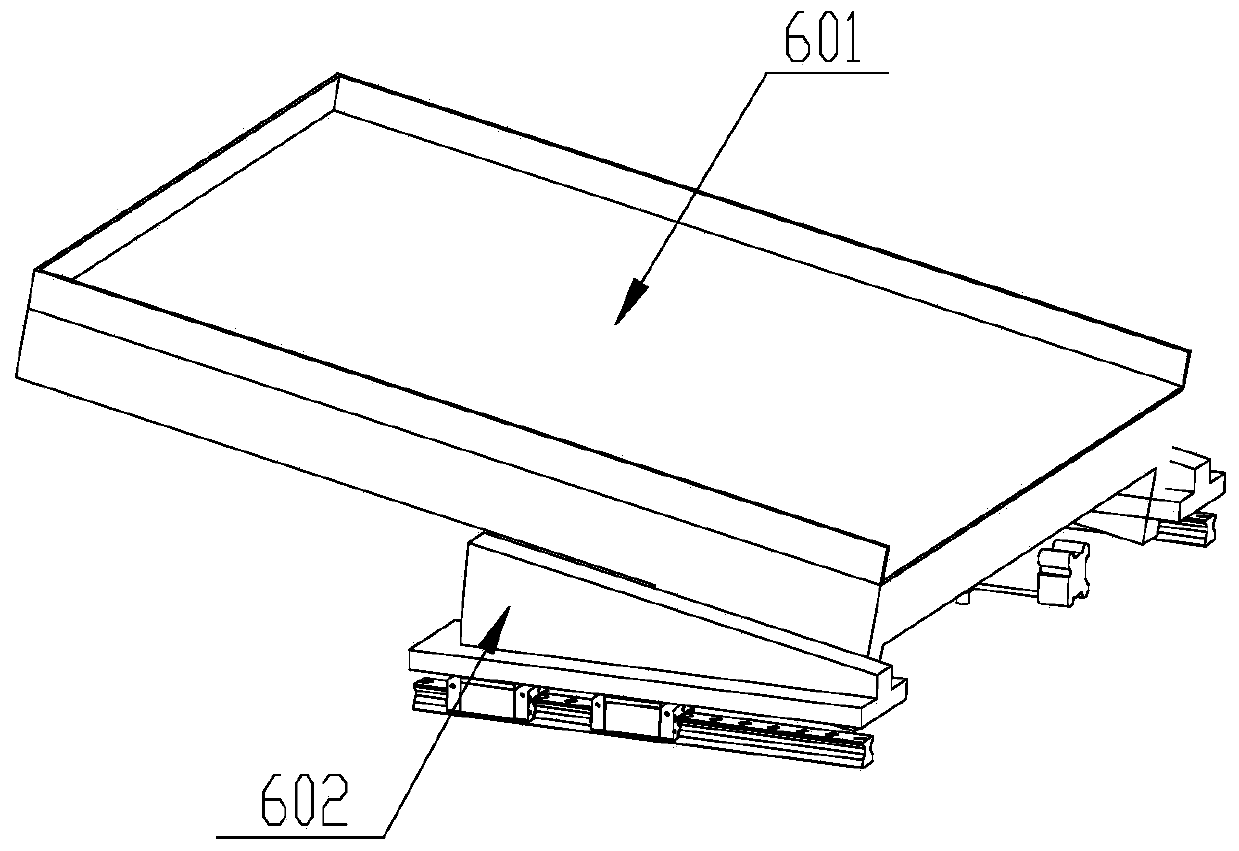

[0047] refer to figure 1 , image 3 The edge skin mechanism 6 includes a material receiving box 601 and a material receiving box fixing seat 602. The material receiving box 601 is obliquely arranged on the upper part of the material receiving box fixing seat 602, and is slidably connected with the material receiving box fixing seat 602. The cartridge holder 602 is disposed on the base 1 and is slidably connected with the base 1 . Specifically, two feeding slide rails are arranged on the base 1 along the conveying direction of the crystal silicon, and a first air cylinder is arranged horizontally between the feeding slide rails, and the first air cylinder is arranged parallel to the feeding slide rails. The first air cylinder is slidingly matched with the material receiving slide rail, that is, the first air cylinder drives the material receiving box 601 to generate displacement along the crystal silicon conveying direction. Simultaneously, a slideway for the material receivi...

Embodiment 2

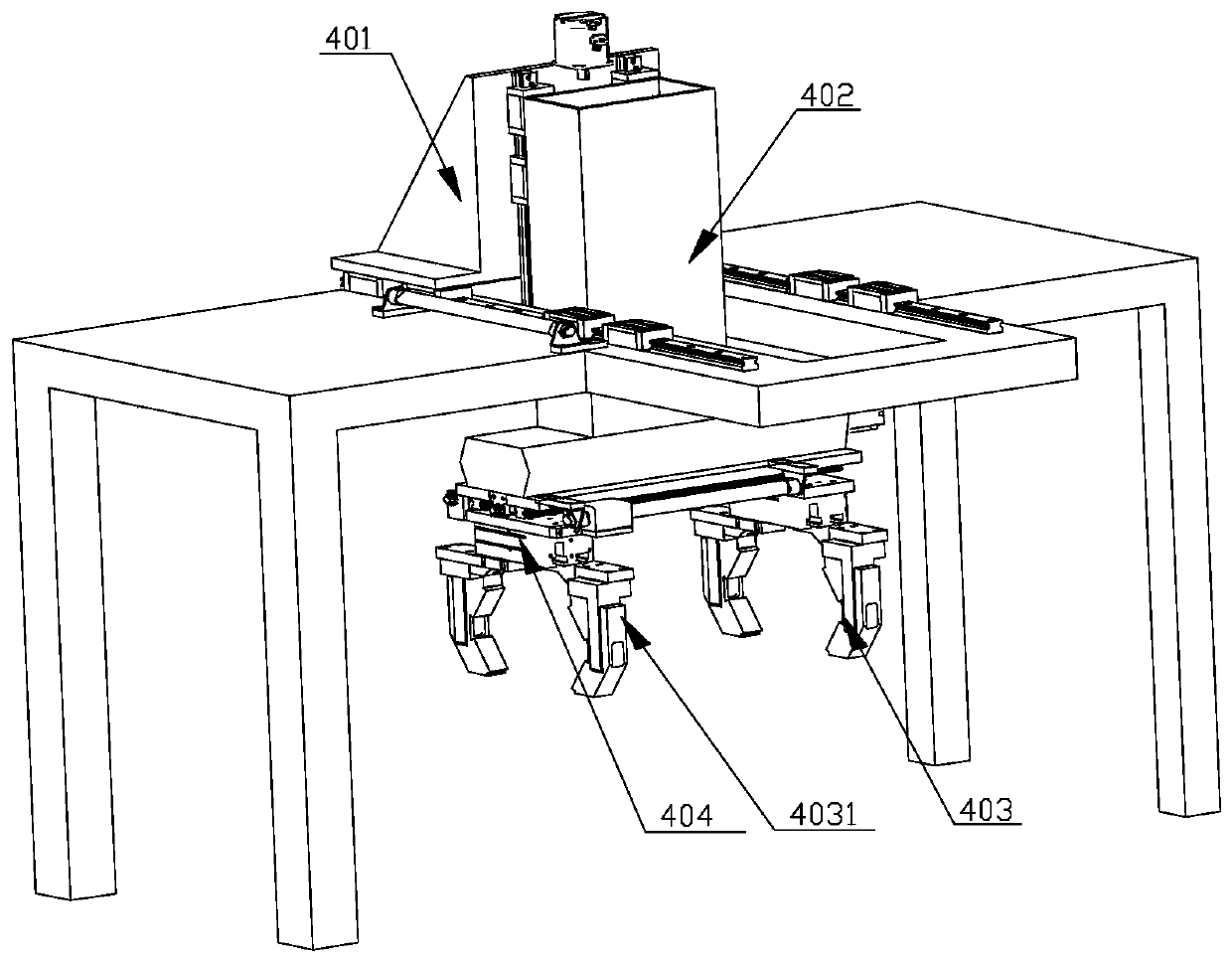

[0050] refer to figure 1 , figure 2 , the feeding mechanism 3 includes a manipulator assembly 4 and a feeding table 5, the feeding table 5 straddles the top of the edge leather mechanism 6, and is fixedly connected to the base 1 through a feeding table bracket. The manipulator assembly 4 is arranged above the loading platform 5 and is slidably connected with the support frame 2 .

[0051] Specifically, the manipulator assembly 4 includes a manipulator fixing base 401, a manipulator supporting base 402 and a jaw assembly 403, the manipulator fixing base 401 is slidably connected with the support frame 2 in the horizontal direction, the manipulator supporting base 402 and the manipulator fixing base 401 Slidingly connected in the vertical direction, the jaw assembly 403 is arranged below the manipulator support base 402 and is slidably connected with the manipulator support base 402 in the horizontal direction.

[0052] In this embodiment, the conveying direction of the silic...

Embodiment 3

[0056] refer to figure 1 , Figure 4 , the square finding mechanism 7 includes a cutting head, and the cutting head includes a cutting channel surrounded by cutting lines through which the crystalline silicon passes and cuts.

[0057] Specifically, the cutting head includes a cutting base 701, a left cutting assembly 702 and a right cutting assembly 703, and the left cutting assembly 702 and the right cutting assembly 703 are arranged on the cutting base 701 at intervals with the central axis of the cutting base 701 as a symmetrical axis , and a cutting channel for the passage of crystal silicon is formed between the two, and the cutting base 701 is slidably connected with the base 1 through the first lead screw 704 . Specifically, the first lead screw 704 is arranged on the base 1 along the horizontal direction, and is located below the cutting base 701. Fixed connection to realize the sliding connection between the cutting base 701 and the base 1.

[0058] The left cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com