Production method of veneer shaving board

A technology for board production and shavings, which is used in wood processing appliances, joining of wooden veneers, and addition of water repellents, etc. It can solve the problems of high formaldehyde emission from veneer particleboard, reducing formaldehyde content of veneer particleboard, and health hazards. , to achieve the effect of high affinity, reducing formaldehyde emission and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

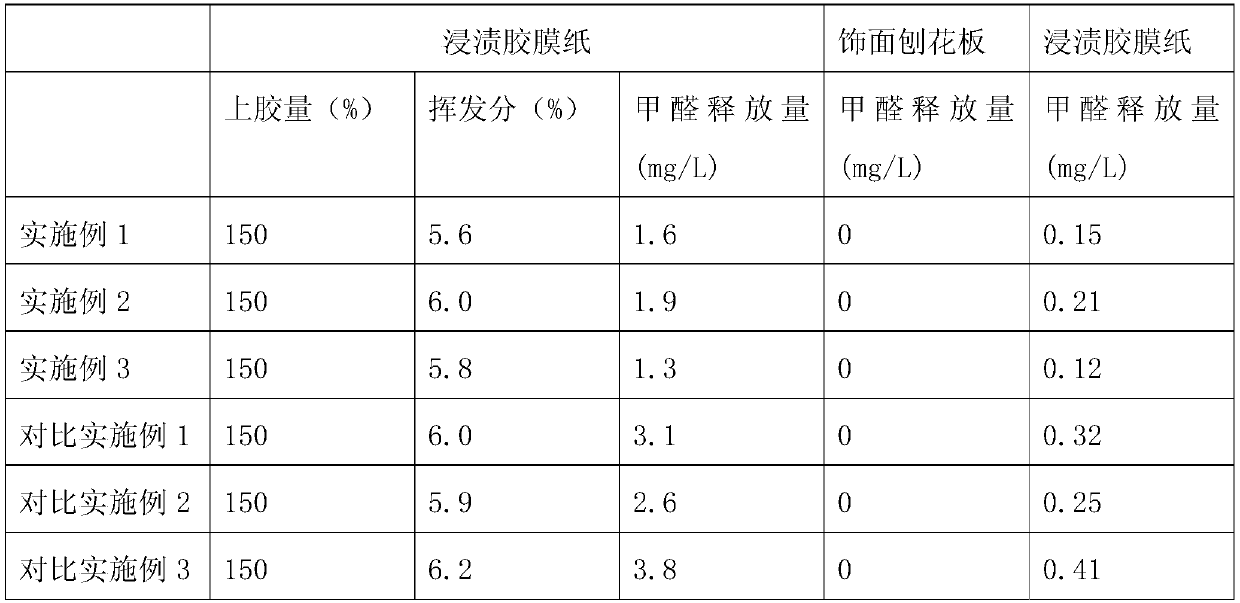

Examples

Embodiment 1

[0020] A kind of facing particle board production method of the present embodiment, comprises the following steps:

[0021] (1) Printing: After the decorative base paper is treated with a sizing agent, the sizing amount of the sizing agent is 1g / m 2 , adopt the gravure printing mode to print, obtain the decorative base paper that is printed with three-dimensional pattern pattern, control pattern pattern thickness is 0.6mm; The preparation method of described sizing agent is: a: cornstarch and water are mixed by mass ratio 1:4 , adding a concentration of 10% sodium hydroxide solution to adjust the pH value to 8-9, adding an oxidizing agent sodium hypochlorite, the amount of an oxidizing agent is 3% of the weight of cornstarch, reacting at a temperature of 35° C. for 2 hours, neutralizing with a concentration of 10% hydrochloric acid solution at the end of the reaction, At the same time, potassium iodide is used to detect the residual amount of sodium hypochlorite. If the residu...

Embodiment 2

[0027] A kind of facing particle board production method of the present embodiment, comprises the following steps:

[0028] (1) Printing: After the decorative base paper is treated with a sizing agent, the sizing amount of the sizing agent is 2g / m 2, adopt the gravure printing mode to print, obtain the decorative base paper that is printed with three-dimensional pattern pattern, control pattern pattern thickness is 0.6mm; The preparation method of described sizing agent is: a: cornstarch and water are mixed by mass ratio 1:4 , adding a concentration of 10% sodium hydroxide solution to adjust the pH value to 8-9, adding an oxidizing agent sodium hypochlorite, the amount of an oxidizing agent is 3% of the weight of cornstarch, reacting at a temperature of 40° C. for 2 hours, neutralizing with a concentration of 10% hydrochloric acid solution at the end of the reaction, At the same time, potassium iodide is used to detect the residual amount of sodium hypochlorite. If the residua...

Embodiment 3

[0034] A kind of facing particle board production method of the present embodiment, comprises the following steps:

[0035] (1) Printing: After the decorative base paper is treated with a sizing agent, the sizing amount of the sizing agent is 1g / m 2 , adopt the gravure printing mode to print, obtain the decorative base paper that is printed with three-dimensional pattern pattern, control the pattern pattern thickness to be 0.8mm; The preparation method of described sizing agent is: a: cornstarch and water are mixed by mass ratio 1:4 Add 10% sodium hydroxide solution to adjust the pH value to 8-9, add oxidizing agent sodium hypochlorite, the amount of oxidizing agent is 3% of the weight of cornstarch, react at a temperature of 40° C. for 2 hours, and neutralize with a concentration of 10% hydrochloric acid solution at the end of the reaction. At the same time, potassium iodide is used to detect the residual amount of sodium hypochlorite. If the residual sodium hypochlorite is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com