Electrochemical testing device and method for observing columnar lithium electrode by atomic force microscope

A technology of atomic force microscope and testing device, which is applied in the direction of measuring device, scanning probe microscopy, scientific instruments, etc., can solve the problems that the volatile electrolyte system cannot be used for detection, the working electrode has a single form, and the structure is complex. Working electrode form, convenient operation, and universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

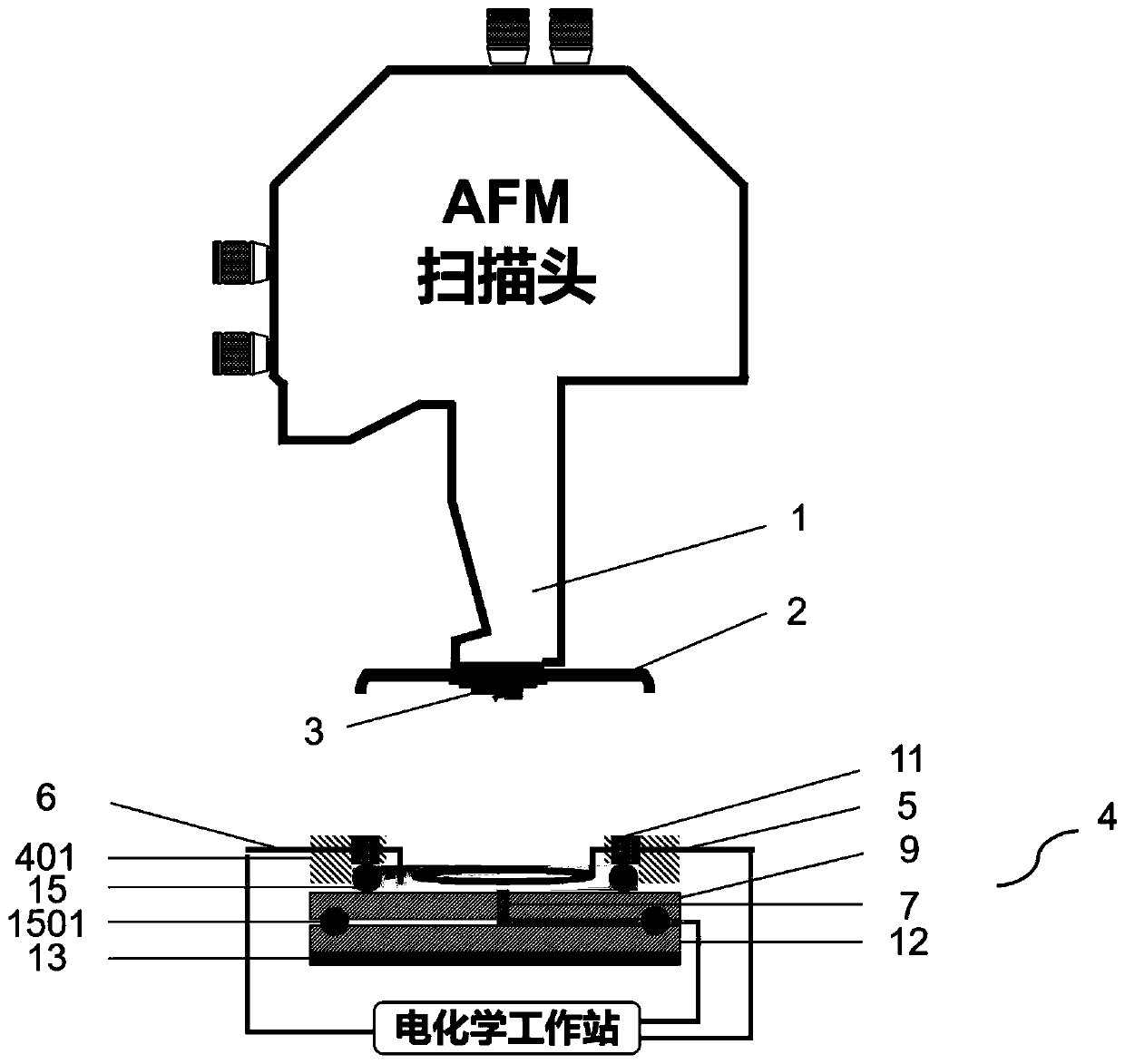

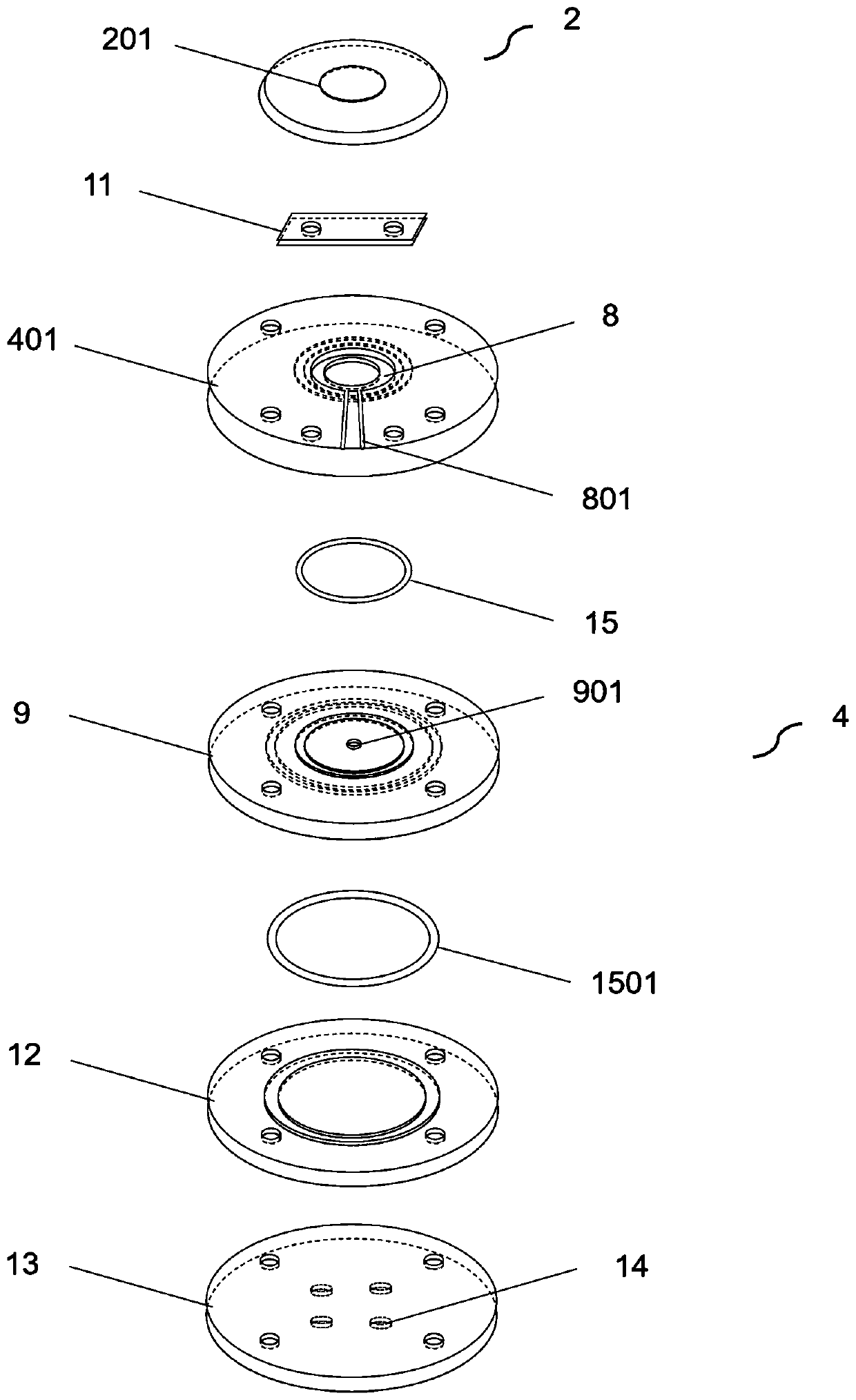

[0032] Aiming at the problem that existing in-situ electrochemical atomic force microscope testing devices can only be applied to sheet-shaped working electrodes, the present invention provides an electrochemical testing device for observing columnar lithium electrodes with an atomic force microscope, which can observe columnar lithium electrodes / electrolytic The deposition / dissolution behavior of metal lithium at the liquid interface and the formation and growth process of SEI film can realize the in-situ electrochemical atomic force microscopy investigation of the interface structure evolution of the volatile electrolyte system of metal lithium battery during charge and discharge.

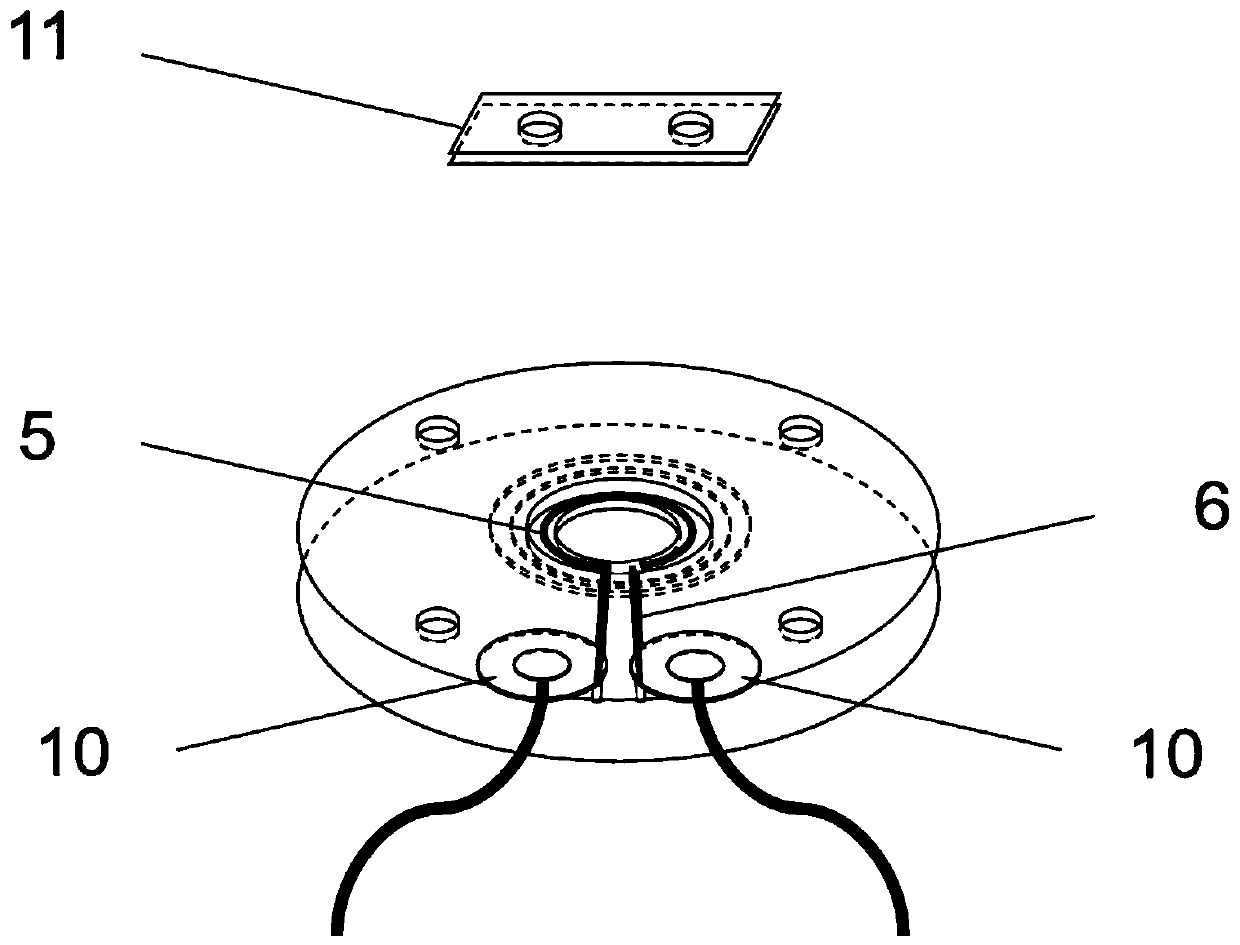

[0033] Such as figure 1 and 2 As shown, the test device includes an atomic force microscope, an electrochemical cell 4 and its internal electrodes, and an electrochemical workstation, and the electrodes include a ring-shaped counter electrode 5, a reference electrode 6 and a working electrode, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com