Epitaxial method of overweight red phosphorus-doped substrate

A technology of substrate and red phosphorus, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of lower yield, unable to solve the problems of gas phase doping composition, difference between epitaxial wafer edge and central SRP, etc., and achieve improvement The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

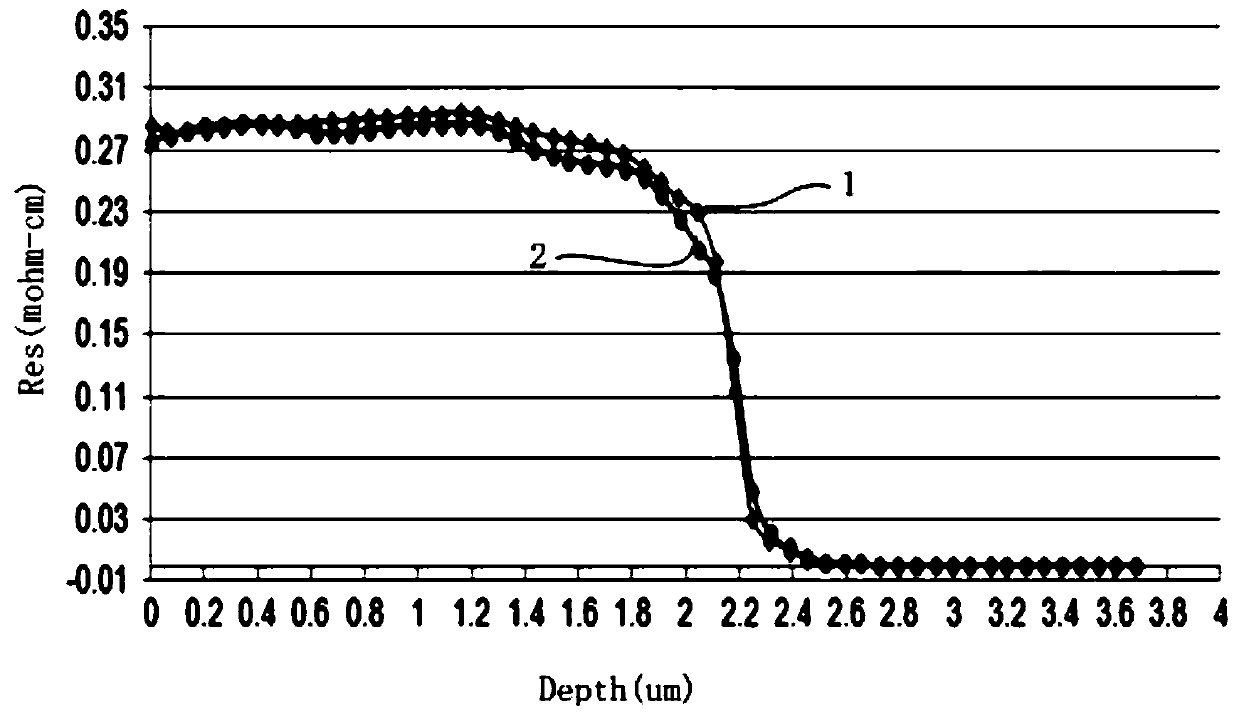

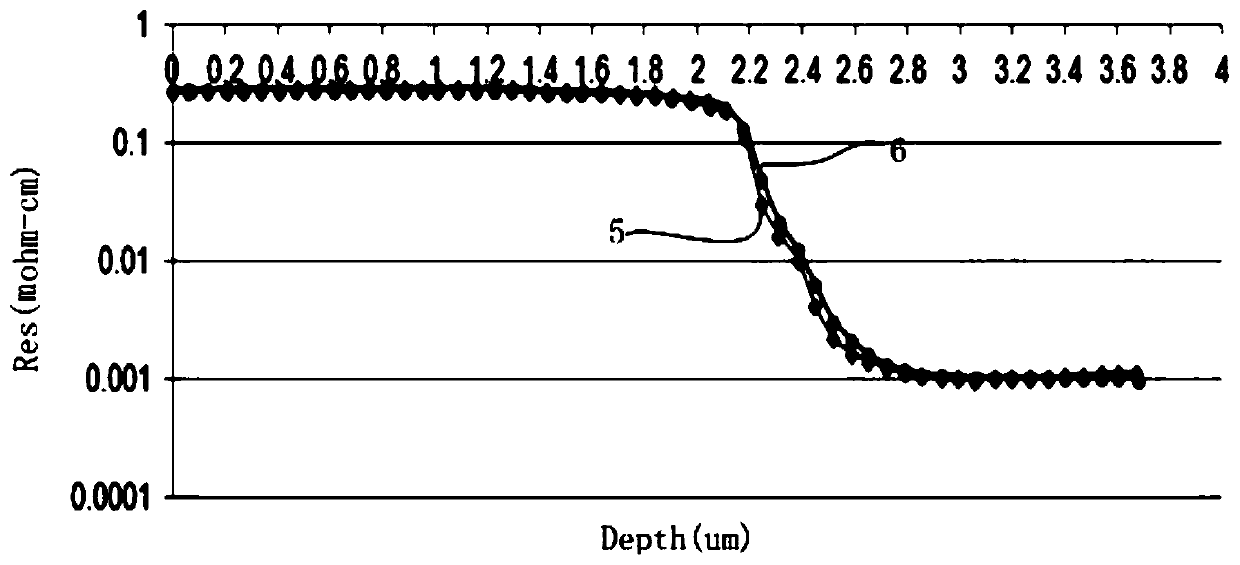

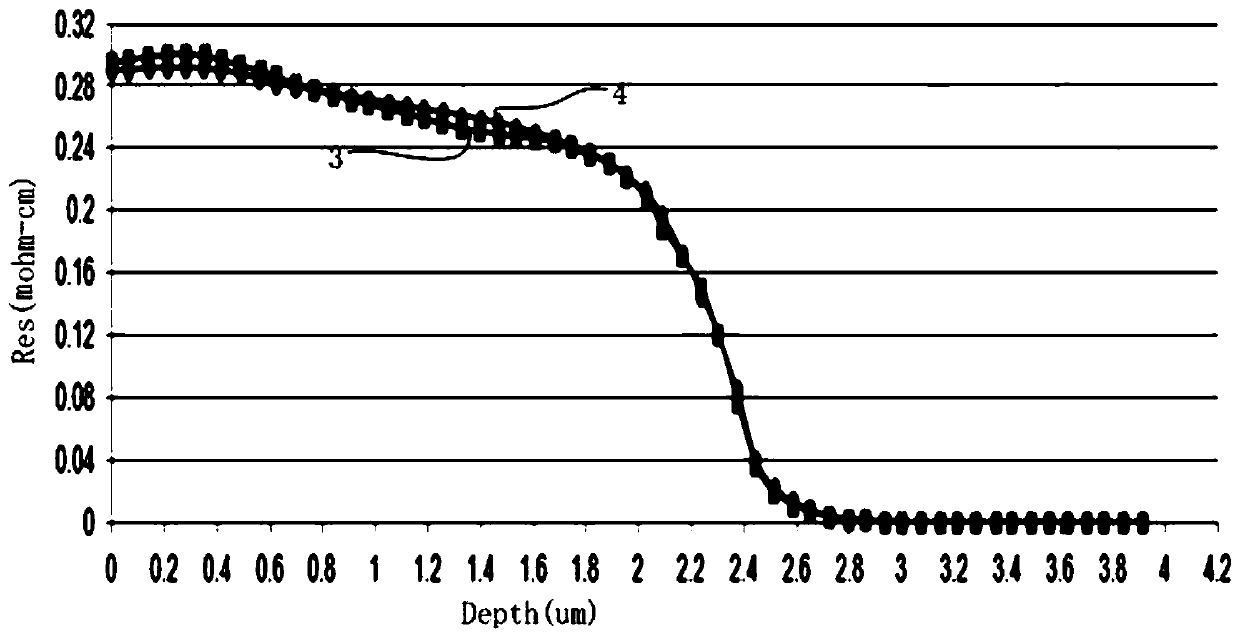

[0030] Step 1: Baking (BAKE) the substrate. The substrate is also referred to as the substrate. The substrate body and the main body of the epitaxial layer are composed of the same element, which is silicon. The substrate in this embodiment is a heavily doped phosphorus substrate, and the resistivity of the substrate is ≤1.0mohm-cm.

[0031] Step 2, growing an intrinsic silicon layer (CAP) with a thickness exceeding the required thickness on the super-heavily doped red phosphorus substrate to absorb impurities in the gas phase. The intrinsic silicon layer is formed by the reaction of trichlorosilane and hydrogen. That is, the single crystal silicon formed by the reaction is deposited on the upper surface of the substrate body to form the intrinsic silicon layer. In this embodiment, the thickness of the intrinsic silicon layer is not higher than 20% of the thickness of the substrate, preferably not higher than 10% of the thickness of the substrate. The required thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com