Perovskite oxide modified diaphragm material for lithium-sulfur battery and lithium-sulfur battery

A perovskite oxide, lithium-sulfur battery technology, applied in the direction of cylindrical shell batteries/batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve lithium metal negative electrode corrosion, battery deactivation, capacity drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a titanium oxide-modified membrane:

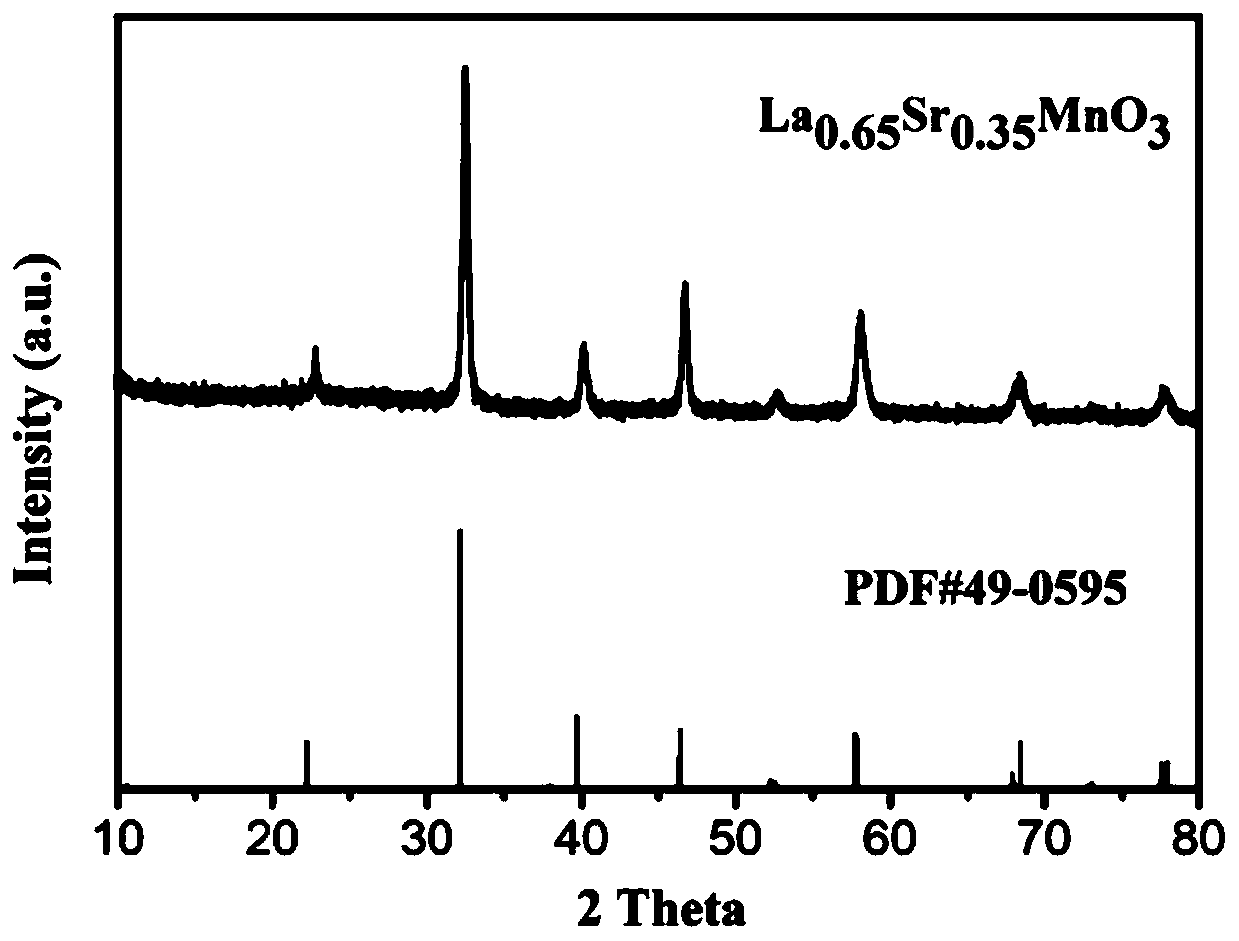

[0039] (1) Perovskite oxide La 0.65 Sr 0.35 MnO 3 synthesis method

[0040] Taking lanthanum nitrate as the measurement basis, dissolve 0.65mmol of lanthanum nitrate, 0.25mmol of strontium nitrate, 0.35mmol of manganese acetate and 1.25mmol of citric acid in deionized water, and slowly add 0.3mmol of ethylene glycol solution dropwise, Stir until clarification, and then stir the obtained clear solution at a high temperature of 60-100°C to form a gel; the obtained gel is carbonized at a high temperature of 600-800°C in air to obtain the target product (La 0.65 Sr 0.35 MnO 3 ).

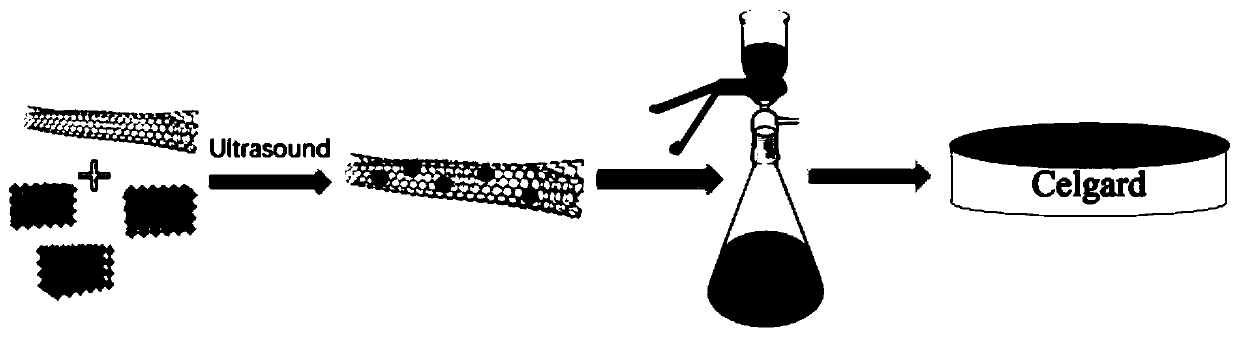

[0041] (2) La 0.65 Sr 0.35 MnO 3 , the conductive agent carbon nanotubes and the binder Nafion are dissolved in ethanol according to the mass ratio of 8:1:1 and ultrasonicated for a certain period of time; the PP diaphragm is used as a filter paper for vacuum filtration for a certain period of time to obtain a functional diaphr...

Embodiment 2

[0044] A method for preparing a titanium oxide-modified diaphragm and an example of a lithium-sulfur battery with the modified diaphragm.

[0045] The perovskite oxide La prepared as in Example 1 0.65 Sr 0.35 MnO 3 Nanoparticles, conductive agent carbon nanotubes and binder Nafion are dissolved in ethanol according to the mass ratio of 7:2:1 and ultrasonicated for a certain period of time; vacuum filtration is carried out for a certain period of time with PP diaphragm as filter paper to obtain the function of using PP diaphragm as the base sex diaphragm. Put the separator in an oven at 60° C. to dry for 24 hours, and punch the obtained modified separator into a disc with a diameter of 16 mm.

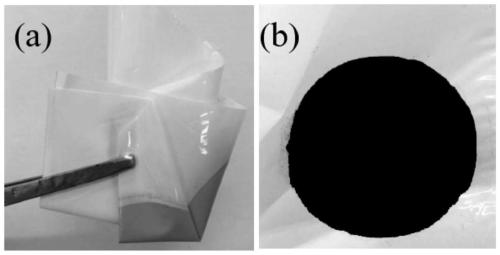

[0046] image 3 (a) is the photo of the perovskite oxide obtained in Example 2 after being folded in half for many times, and (b) is the photo of the perovskite oxide obtained in Example 2 after being folded in half for many times and finally recovers itself Expanded photo. The coati...

Embodiment 3

[0050] A preparation method of a titanium oxide-modified diaphragm:

[0051] With reference to the La prepared in Example 1 0.65 Sr 0.35 MnO 3 Nanoparticles, conductive agent carbon nanotubes and binder Nafion are dissolved in ethanol according to the mass ratio of 6:3:1 and ultrasonicated for a certain period of time; vacuum filtration is carried out for a certain period of time with PP diaphragm as filter paper to obtain the function of using PP diaphragm as the base sex diaphragm. Put the separator in an oven at 60° C. to dry for 24 hours, and punch the obtained modified separator into a disc with a diameter of 16 mm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap