Preparation method and application of slow-release antioxidant microcapsule

A microcapsule, antioxidant technology, applied in the direction of food ingredients as antioxidants, application, food science, etc., can solve the problem of short useful time of food antioxidants, achieve strong sustained release effect, small impact, and inhibit food oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

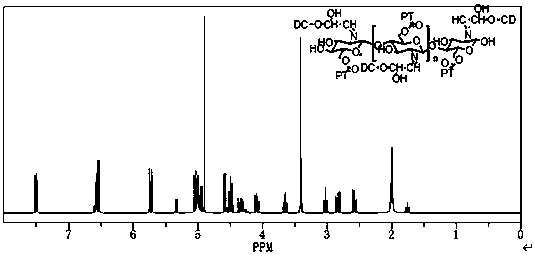

[0044] (1) Preparation of tea polyphenols and chitosan coupling products

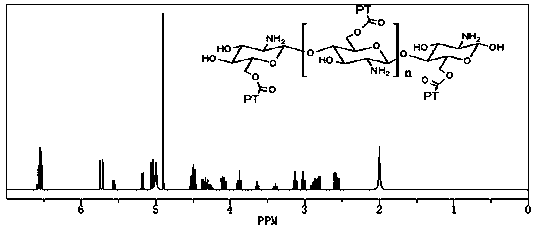

[0045] (1.1) First, weigh 5g of chitosan, add it into a three-neck flask with a stirrer, add 100mL of acetic acid with a mass concentration of 1%, put it in a constant temperature water bath, heat it to 25°C and stir for 25min, add the mass concentration After adjusting pH=4 for 1% acetic acid, add 60 g of benzyl chloroformate, and react at a constant temperature of 25° C. for 5 hours to obtain amino-protected chitosan;

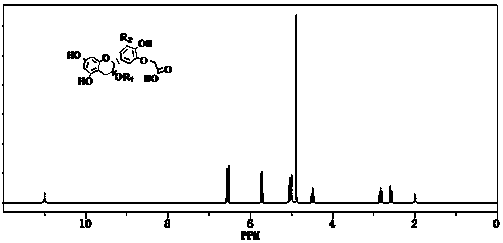

[0046] (1.2) Weigh 25g of tea polyphenols, add it to a three-necked flask with a stirrer, add 2g of NaOH, put it into a constant temperature water bath, add 20g of monochloroacetic acid after heating to 50°C, and react at 50°C for 2 hours while stirring at a constant temperature. Obtain carboxymethyl tea polyphenols;

[0047] (1.3) Weigh 3g of amino-protected chitosan, add it to a round-bottomed flask, add 20g of carboxymethyl tea polyphenol after heating to 70°C, and react at 70°C fo...

Embodiment 2

[0055] (1) Preparation of tea polyphenols and chitosan coupling products

[0056] (1.1) First, take 5g chitosan, add in the there-necked flask with agitator, add 100mL of acetic acid with a mass concentration of 2% and put it into a constant temperature water bath, heat to 25°C and stir for 30min, add a mass concentration of 2% acetic acid was added to adjust the pH to 4.5, and then 75 g of benzyl chloroformate was added, and reacted at a constant temperature of 25° C. for 6 hours to obtain amino-protected chitosan;

[0057] (1.2) Weigh 25g of tea polyphenols, add it to a three-necked flask with a stirrer, add 2g of NaOH, put it into a constant temperature water bath, add 18g of monochloroacetic acid after heating to 55°C, and react at 55°C for 2h under constant temperature stirring. Obtain carboxymethyl tea polyphenols;

[0058] (1.3) Weigh 3g of amino-protected chitosan, add it to a round-bottomed flask, heat to 75°C, add 25g of carboxymethyl polyphenols, and react at 75°C ...

Embodiment 3

[0065] (1) Preparation of tea polyphenols and chitosan coupling products

[0066] (1.1) First, weigh 5g of chitosan, add it into a three-neck flask with a stirrer, add 100mL of acetic acid with a mass concentration of 3%, put it in a constant temperature water bath, heat it to 25°C and stir for 20min, add the mass concentration After adjusting pH=3.5 for 3% acetic acid, add 90 g of benzyl chloroformate, and react at a constant temperature of 30° C. for 4 hours to obtain amino-protected chitosan;

[0067] (1.2) Weigh 25g of tea polyphenols, add it to a three-necked flask with a stirrer, add 2g of NaOH, put it into a constant temperature water bath, add 25g of monochloroacetic acid after heating to 60°C, and react at 60°C for 3h under constant temperature stirring. Obtain carboxymethyl tea polyphenols;

[0068] (1.3) Weigh 4g of amino-protected chitosan, add it to a round bottom flask, add 20g of carboxymethyl tea polyphenol after heating to 80°C, and react at 80°C for 5h to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com