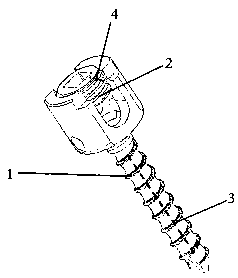

Carbon fiber pedicle screw and manufacturing method thereof

A technology of a pedicle screw and a manufacturing method, which are applied in the field of medical implants to achieve the effects of solving stress shielding, inducing secondary fractures, and convenient and intuitive three-dimensional positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In Example 1, medical grade non-propeller chopped carbon fiber (0.1 kg / min) was added to the medical grade polyether ether ketone (feeding speed 1 kg / min) pelletizing twin screw through the side feeding port for granulation to obtain carbon fiber Reinforced polyetheretherketone pellets, denoted as P1; the injection molding spline test on P1, its modulus is 5.2GPa.

Embodiment 2

[0031] In Example 2, the medical grade non-propeller chopped carbon fiber (0.2 kg / min) was added to the medical grade polyetheretherketone (feeding speed 1 kg / min) pelletizing twin screw through the side feeding port for granulation to obtain the carbon fiber Reinforced polyetheretherketone pellets, denoted as P2; the injection molding spline test on P2, its modulus is 7.2GPa.

Embodiment 3

[0032] In Example 3, medical grade non-propeller chopped carbon fiber (0.3 kg / min) was added to the medical grade polyether ether ketone (feeding speed 1 kg / min) pelletizing twin screw through the side feeding port for granulation to obtain carbon fiber Reinforced polyether ether ketone pellets, denoted as P3; the injection molding spline test of P3, its modulus is 9.6GPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com