A kind of sewage treatment equipment based on livestock and poultry breeding

A sewage treatment equipment, livestock and poultry breeding technology, applied in water/sewage treatment, animal husbandry wastewater treatment, water/sewage multi-stage treatment, etc. Reasonable reuse of resources, easy replacement and processing, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

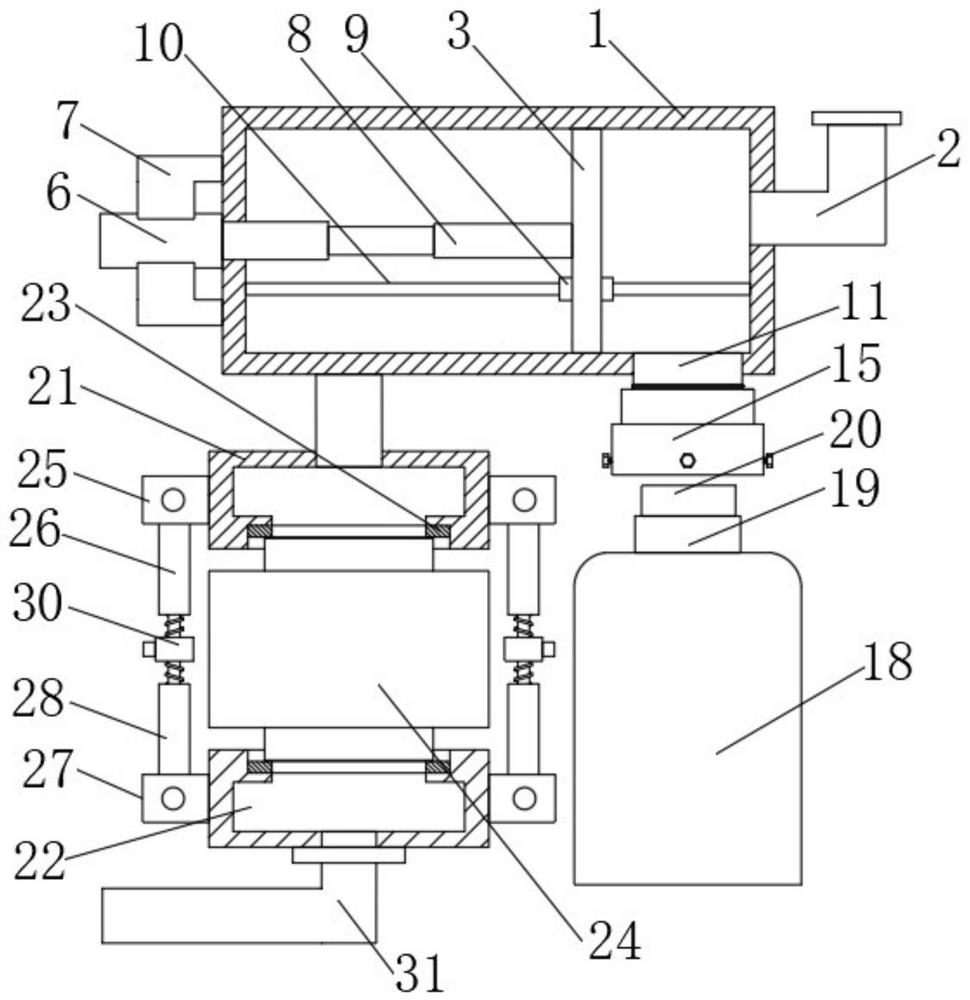

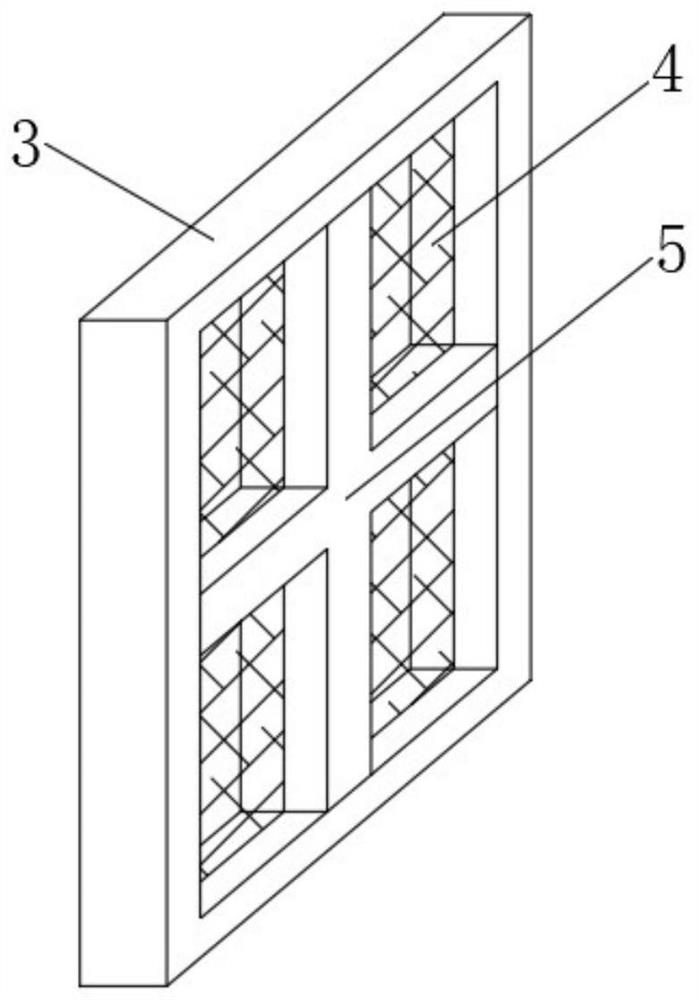

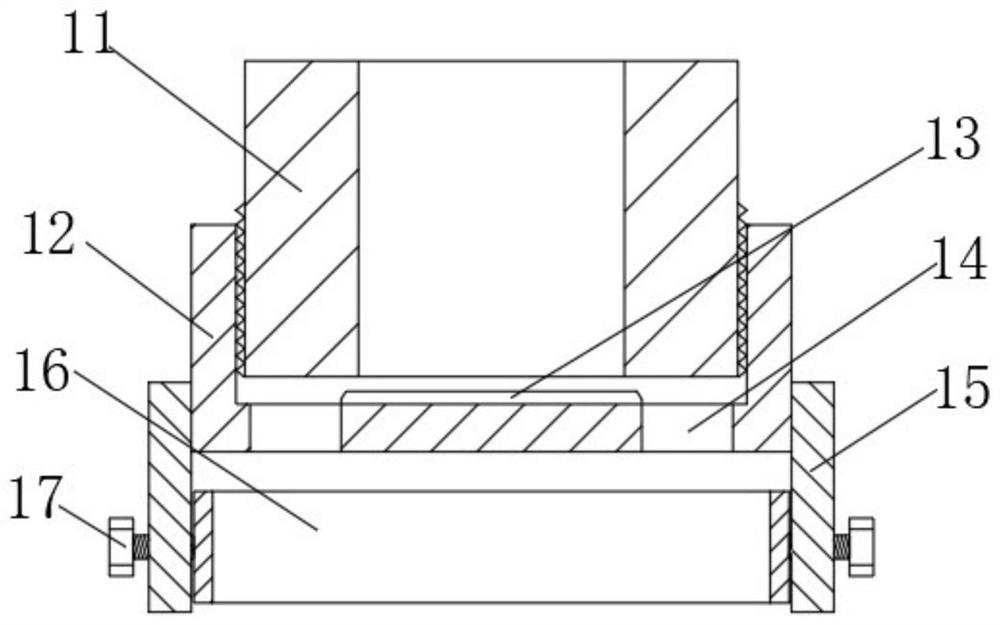

[0027] see Figure 1-5 , a kind of sewage treatment equipment based on livestock and poultry breeding, comprising a filter box 1, a waste residue collection bucket 18, a first installation box 21 and a second installation box 22, the side wall of the filter box 1 is fixedly installed with a sewage input pipe 2, the filter box 1 A sliding frame 3 is slidingly connected in the middle, and a filter residue net 4 is arranged inside the sliding frame 3, a hydraulic cylinder 6 is fixedly installed on one end of the filter box 1, a connecting column 8 is fixedly connected to the output end, and the other end of the connecting column 8 is fixedly connected to the sliding frame 3 One end of the filter box 1 is fixedly connected with a fixed cylinder 11 on one side of the bottom end of the filter box 1. The fixed cylinder 11 is fixed through internal and external threads and fitted with a fitting cylinder 12. The inner bottom of the fitting cylinder 12 is fixedly connected with a gasket ...

Embodiment 2

[0030] see Figure 1-5 , made further improvement on the basis of embodiment 1: the inner side of the sliding frame 3 is fixedly connected with a cross 5, and the cross 5 is located at both ends of the filter residue net 4; one end of the filter box 1 is fixedly connected with a stable frame 7, and the hydraulic cylinder 6 is positioned at the stable frame 7 middle part; the grooves of the first installation box 21 and the second installation box 22 are fixedly connected with a second sealing ring 23 , and the second sealing ring 23 is supported on both ends of the filter cartridge 24 .

[0031] In the present embodiment, by arranging the cross 5, it can be ensured that the filter slag screen 4 has better strength in use, and the stable frame 7 can be used to ensure that the hydraulic cylinder 6 has better stability in use, and the second sealing ring 23 can This makes the filter cartridge 24 more airtight during installation and avoids leakage of sewage.

Embodiment 3

[0033] see Figure 1-5 , On the basis of embodiment 1, a further improvement is made: the middle part of the sliding frame 3 is fixedly connected with a matching cylinder 9, the middle part of the filter box 1 is fixedly connected with a fixed column 10, and the matching cylinder 9 is slidably connected to the side wall of the fixed column 10.

[0034] In this embodiment, the hydraulic cylinder 6 drives the sliding frame 3 to slide through the connecting column 8, and then the sliding frame 3 uses the matching cylinder 9 to slide on the side wall of the fixed column 10 in the process of sliding left and right to ensure that the matching cylinder 9 slides smoothly. stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com