Modified polypropylene recovery material and preparation method thereof

A technology for recycled material and polypropylene, which is applied in the field of modified polypropylene recycled material and its preparation, can solve the problems that the modification cannot meet the standard of new polypropylene material, etc., and achieves improved dispersion performance, excellent rigidity and toughness balance, and good dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 75 parts of recycled polypropylene, 10 parts of high-density polyethylene, 5 parts of polyethylene grafted acrylic acid, 0.01 part of antioxidant and 2 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane together in a high-speed mixer and mixed for 3 minutes, then put the mixture into the extruder, add 10 parts of alkali-free glass fiber from the glass fiber port, extrude and cut into pellets to obtain modified polypropylene recycled material.

[0031] The temperature of each section of the barrel of the twin-screw extruder is set as follows: 180°C for zone 1, 185°C for zone 2, 195°C for zone 3, 195°C for zone 4, 200°C for zone 5, 200°C for zone 6, and 205°C for the die. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation.

Embodiment 2

[0033] 30 parts of recycled polypropylene, 30 parts of high-density polyethylene, 15 parts of polyethylene grafted acrylic acid, 0.02 parts of antioxidant and 0.5 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane together in a high-speed mixer and mixed for 4 minutes, then the mixture was added to the extruder, 25 parts of alkali-free glass fiber was added from the glass fiber port, extruded and pelletized to obtain modified polypropylene recycled material.

[0034] The temperature of each section of the barrel of the twin-screw extruder is set as follows: 180°C for zone 1, 185°C for zone 2, 195°C for zone 3, 195°C for zone 4, 210°C for zone 5, 220°C for zone 6, and 205°C for the die. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation.

Embodiment 3

[0036] 52 parts of recycled polypropylene, 20 parts of high-density polyethylene, 10 parts of polyethylene grafted acrylic acid, 0.02 parts of antioxidant and 1 part of 2,5-dimethyl-2,5-bis(tert-butyl peroxy ) hexane together in a high-speed mixer and mixed for 5 minutes, then put the mixture into the extruder, add 18 parts of alkali-free glass fiber from the glass fiber port, extrude and cut into pellets to obtain modified polypropylene recycled material.

[0037] The temperature of each section of the barrel of the twin-screw extruder is set as follows: 180°C for zone 1, 185°C for zone 2, 195°C for zone 3, 195°C for zone 4, 200°C for zone 5, 200°C for zone 6, and 205°C for the die. The extruded strips are cooled to room temperature through a circulating water tank, dried by a blower, and then entered into a pelletizer for granulation.

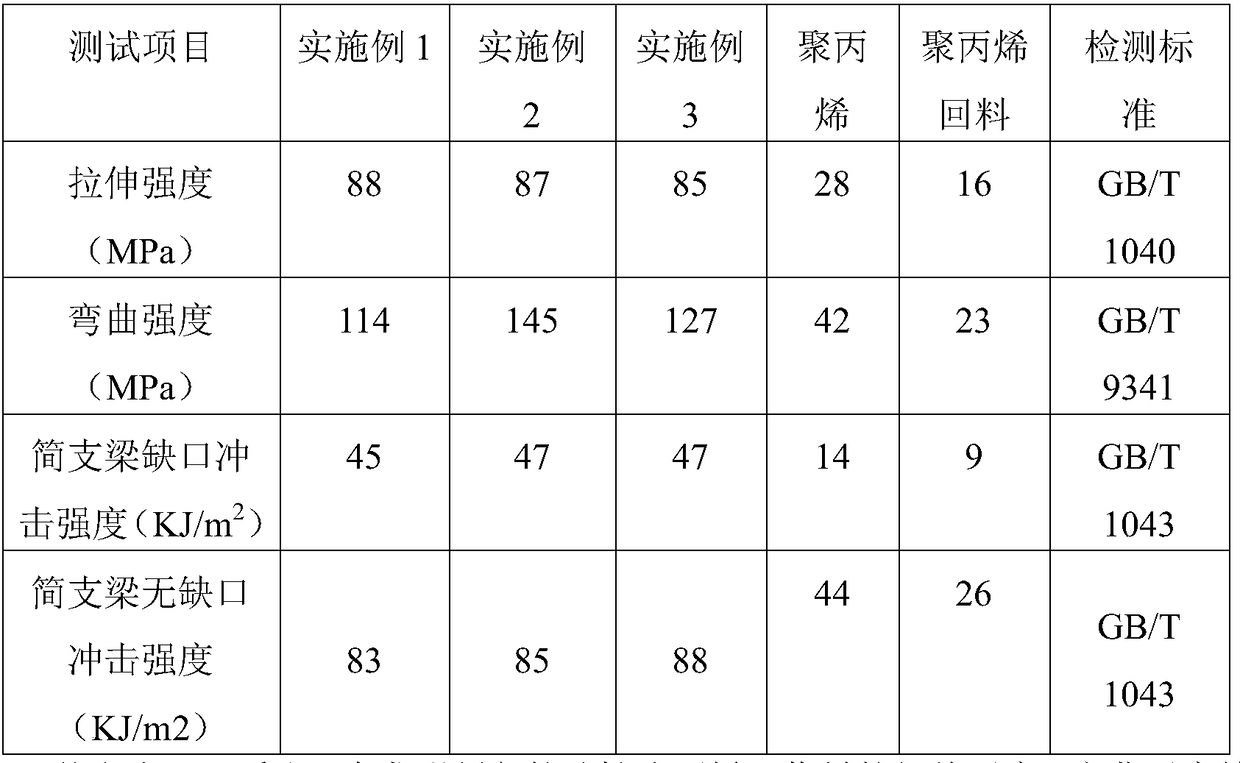

[0038] The modified polypropylene recycled materials prepared in the above-mentioned Examples 1-3 were molded into splines through standard ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com