Method for continuously synthesizing cyclohexanecarboxylic acid

A technology for the synthesis of cyclohexyl formic acid, which is applied in the preparation of carboxylic acids by ozone oxidation, organic chemistry, etc., can solve the problems that the conversion rate of the synthesis reaction is difficult to reach 100%, it is not conducive to the maximization of enterprise benefits, and the synthesis reaction cycle is long. The effect of shortening the synthesis reaction cycle, benefiting enterprise benefits, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

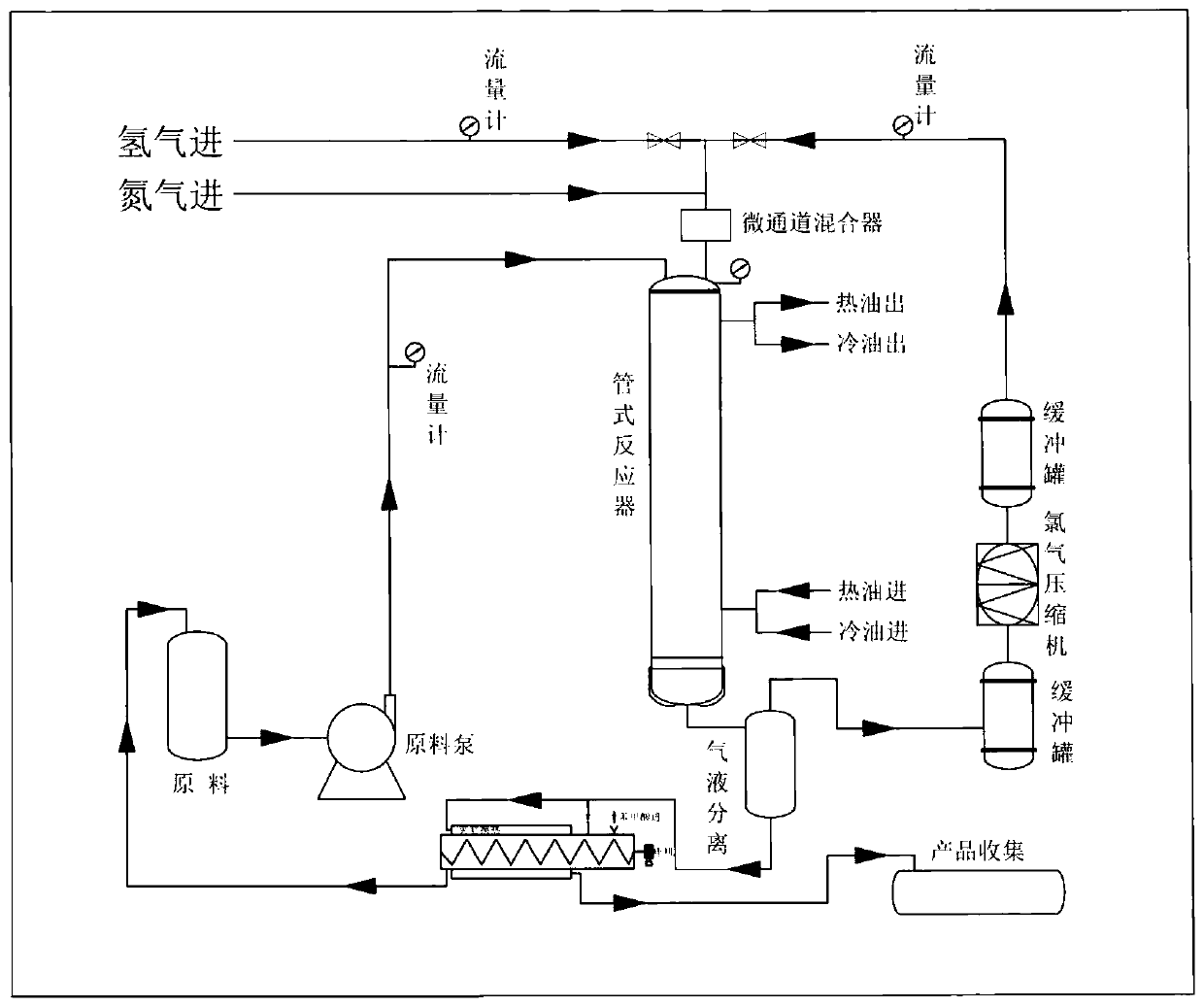

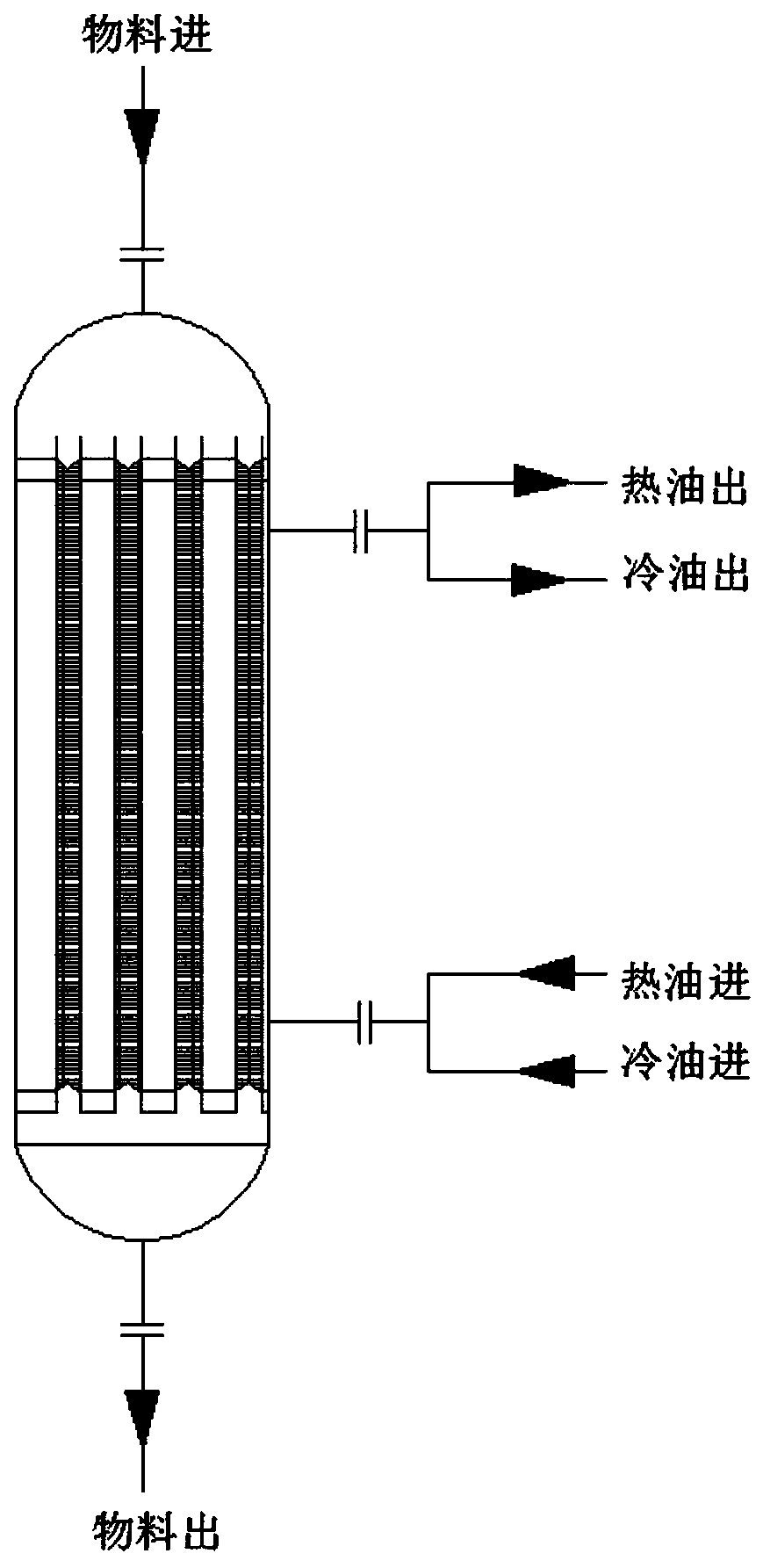

[0032] A method for continuous synthesis of cyclohexyl formic acid, comprising the following steps:

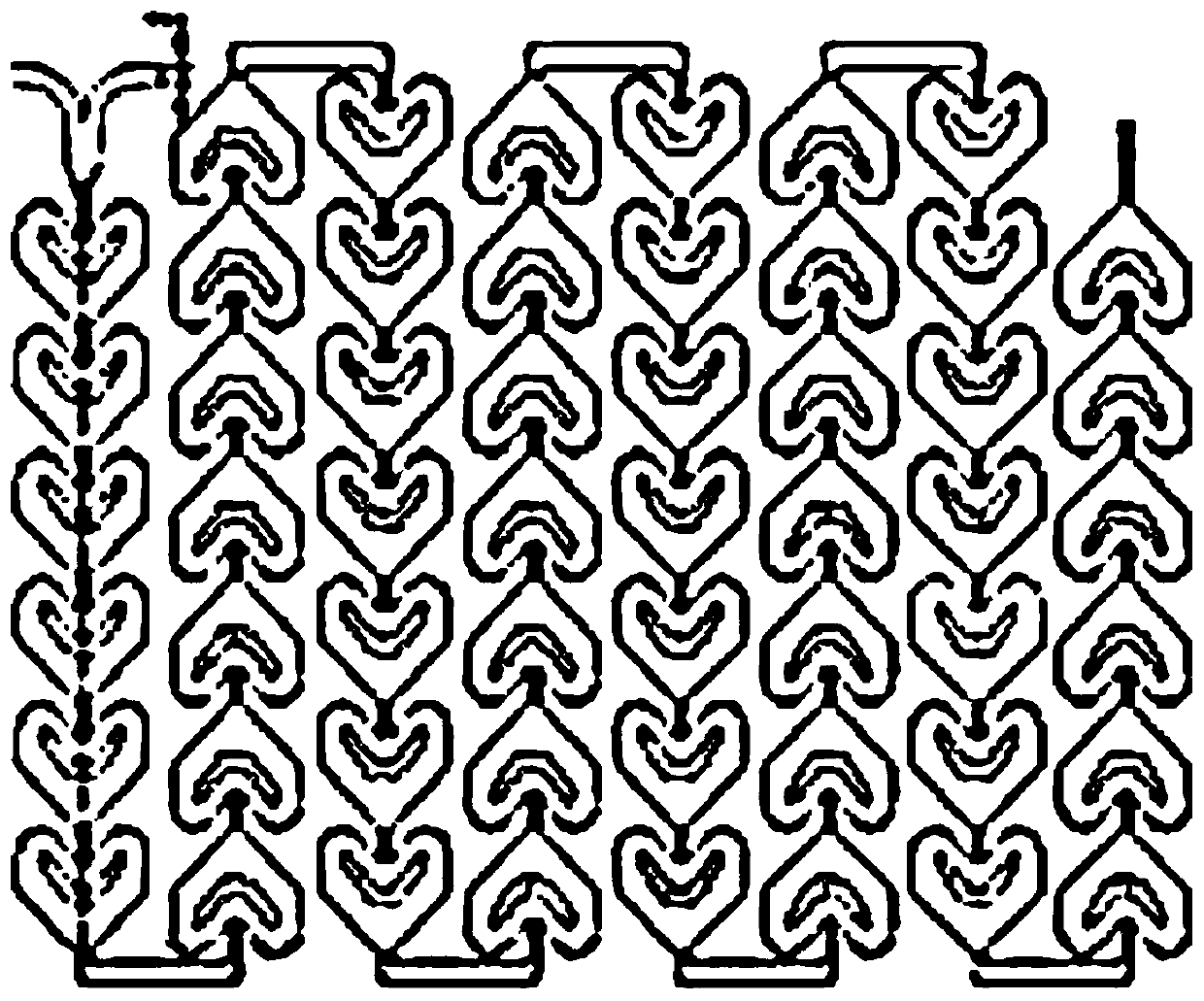

[0033] 1) Preheating by mixing benzoic acid and solvent cyclohexyl formic acid solvent: Benzoic acid is added through the front section of Jiaolong, then solvent cyclohexyl formic acid is added, and it is transported forward in Jiaolong, and the heated cyclohexyl formic acid product in Jiaolong’s jacket acts as a heating The material in the Jiaolong, heating the material in the Jiaolong back feeds the cyclohexyl formic acid product in the cooling jacket, the hot benzoic acid and solvent cyclohexyl formic acid coming out of the Jiaolong enter the raw material tank to obtain preheated benzoic acid and preheated cyclohexyl formic acid, and The temperature of the preheated benzoic acid and the preheated cyclohexyl formic acid is controlled at 80°C, and the cooled cyclohexyl formic acid product enters the finished product tank;

[0034] 2) Emulsion preparation: mix the preheated be...

Embodiment 2

[0038] A method for continuous synthesis of cyclohexyl formic acid, comprising the following steps:

[0039] 1) Preheating by mixing benzoic acid and solvent cyclohexyl formic acid solvent: Benzoic acid is added through the front section of Jiaolong, then solvent cyclohexyl formic acid is added, and it is transported forward in Jiaolong, and the heated cyclohexyl formic acid product in Jiaolong’s jacket acts as a heating The material in the Jiaolong, heating the material in the Jiaolong back feeds the cyclohexyl formic acid product in the cooling jacket, the hot benzoic acid and solvent cyclohexyl formic acid coming out of the Jiaolong enter the raw material tank to obtain preheated benzoic acid and preheated cyclohexyl formic acid, and The temperature of the preheated benzoic acid and the preheated cyclohexyl formic acid is controlled at 95° C., and the cooled cyclohexyl formic acid product enters the finished product tank;

[0040] 2) Emulsion preparation: mix the preheated ...

Embodiment 3

[0044] A method for continuous synthesis of cyclohexyl formic acid, comprising the following steps:

[0045] 1) Preheating by mixing benzoic acid and solvent cyclohexyl formic acid solvent: Benzoic acid is added through the front section of Jiaolong, then solvent cyclohexyl formic acid is added, and it is transported forward in Jiaolong, and the heated cyclohexyl formic acid product in Jiaolong’s jacket acts as a heating The material in the Jiaolong, heating the material in the Jiaolong back feeds the cyclohexyl formic acid product in the cooling jacket, the hot benzoic acid and solvent cyclohexyl formic acid coming out of the Jiaolong enter the raw material tank to obtain preheated benzoic acid and preheated cyclohexyl formic acid, and The temperature of the preheated benzoic acid and the preheated cyclohexyl formic acid is controlled at 110° C., and the cooled cyclohexyl formic acid product enters the finished product tank;

[0046] 2) Emulsion preparation: mix the preheated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com