Wind-blown polymerized vegetable oil as well as preparation method and application thereof

A vegetable oil, wind blowing technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems that the performance cannot fully meet the production requirements of the product, cannot improve the lubricating performance of the product, and is difficult to biodegrade, so as to improve the lubricating performance and The effect of kinematic viscosity, good oil solubility and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

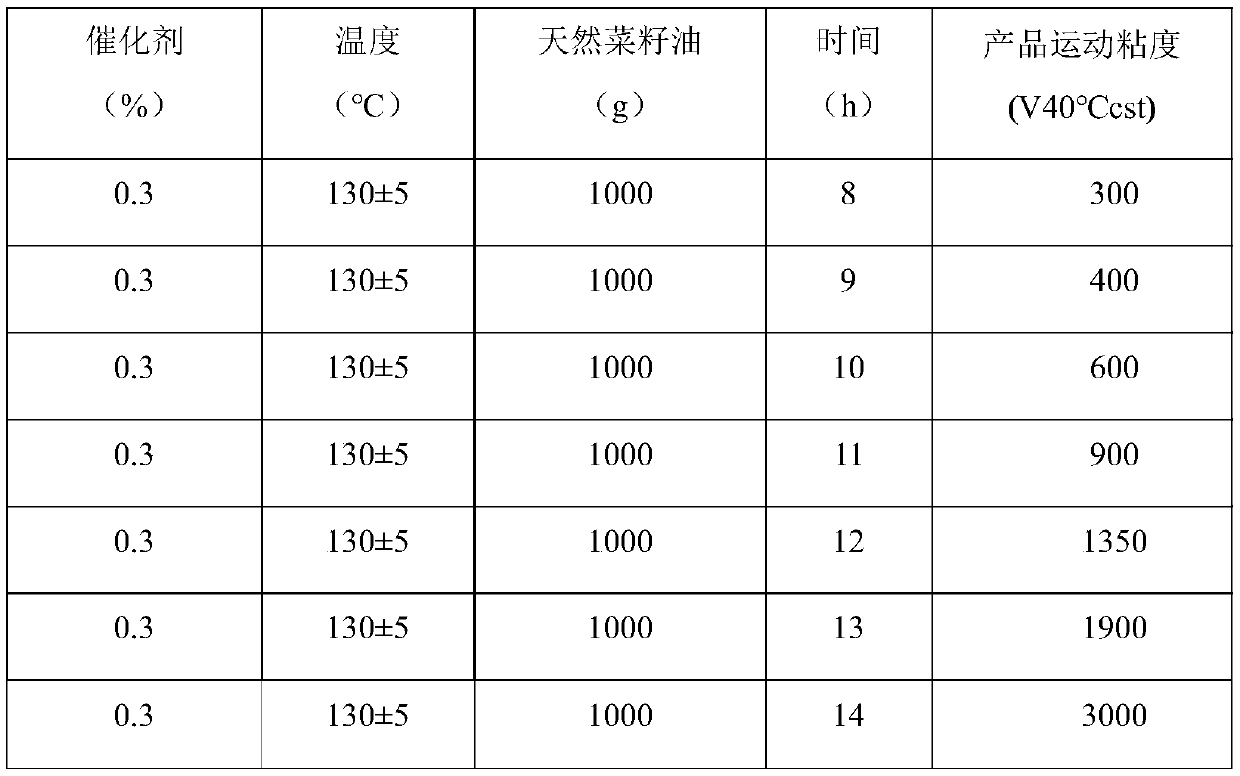

[0019] Weigh 1000g of natural rapeseed oil, add 3g of composite catalyst (made by mixing aluminum oleate and cobalt naphthenate at a mass ratio of 1:1), stir and react under normal pressure at 130±5°C for 8, 9, 10, At 11, 12, 13, and 14 hours, air was continuously blown in during the reaction process, and wind-blown polymerized vegetable oils with different kinematic viscosities were obtained. The results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2

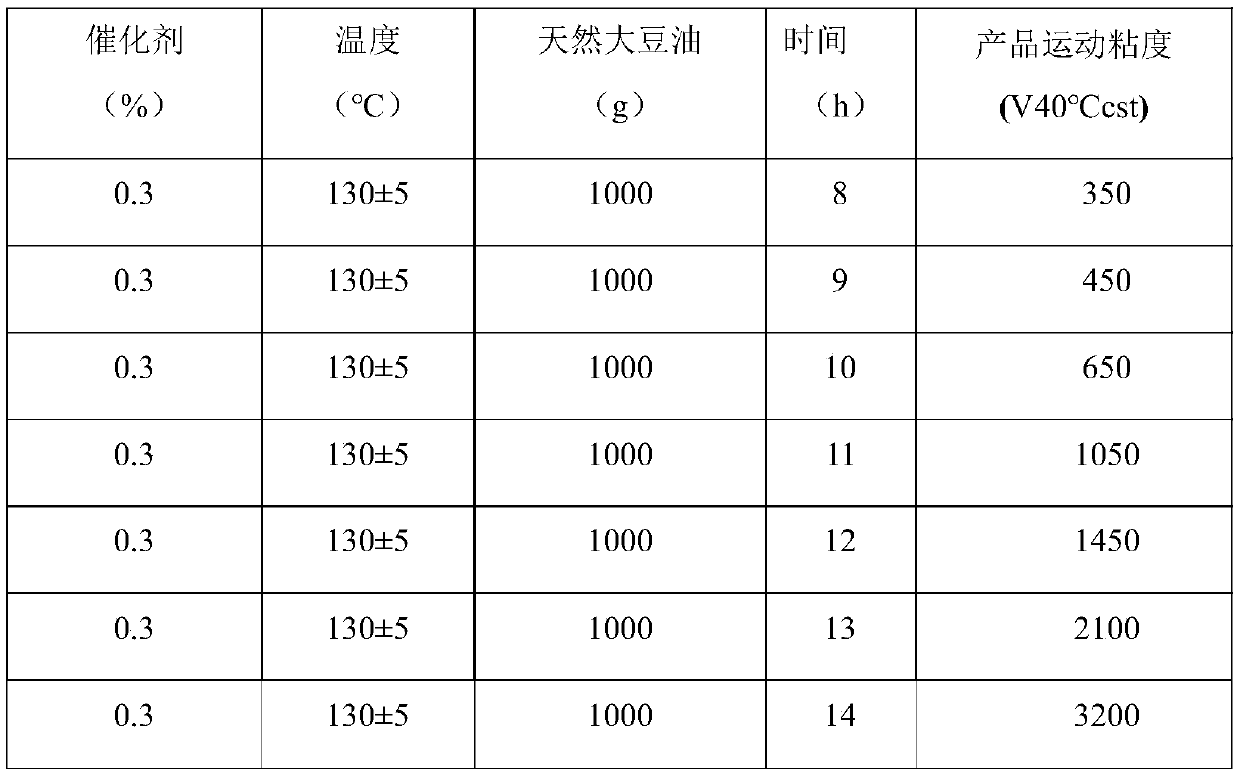

[0023] Weigh 1000g of natural soybean oil, add 3g of composite catalyst (made by mixing aluminum oleate and cobalt naphthenate at a mass ratio of 1:1), stir and react under normal pressure at 130±5°C 8, 9, 10, 11 , 12, 13, and 14 hours, the air was continuously blown in during the reaction process to obtain wind-blown polymerized vegetable oils with different kinematic viscosities, and the results are shown in Table 2.

[0024] Table 2

[0025]

Embodiment 3

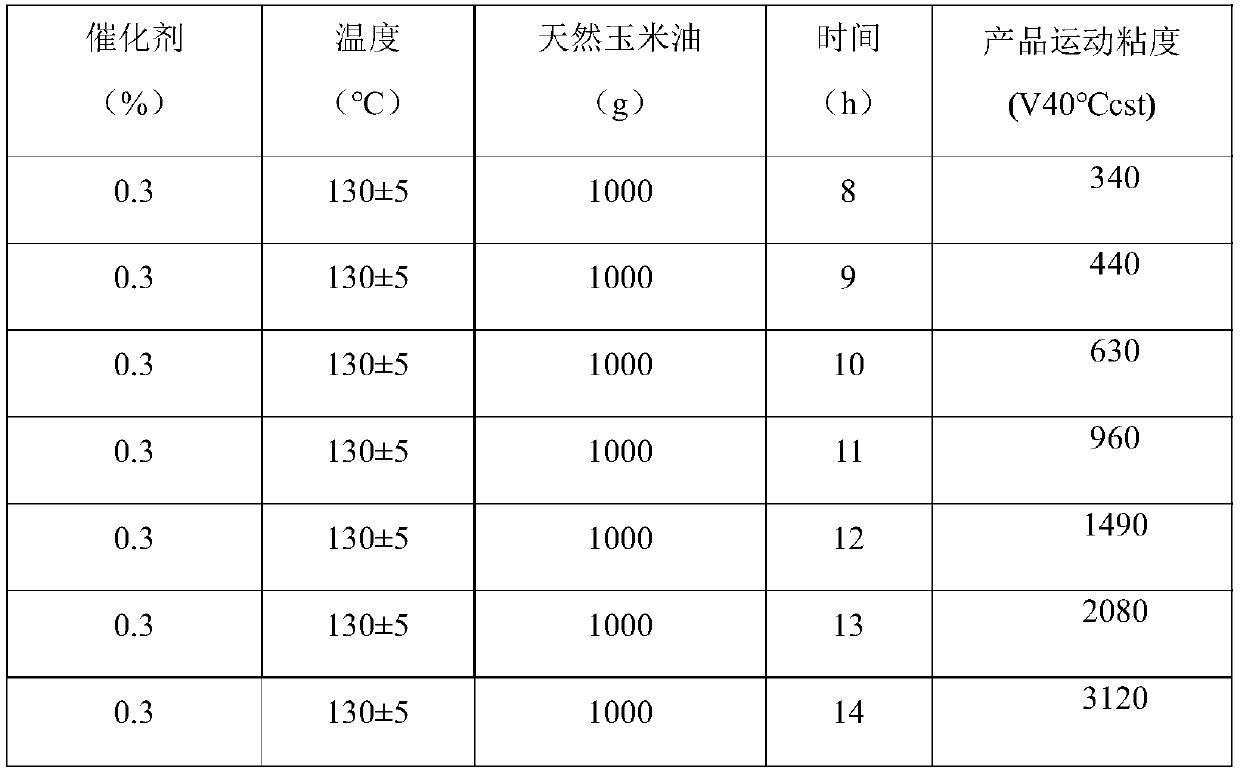

[0027] Weigh 1000g of natural corn oil, add 3g of composite catalyst (made by mixing aluminum oleate and cobalt naphthenate at a mass ratio of 1:1), stir and react under normal pressure at 130±5°C for 8, 9, 10, 11 , 12, 13, and 14 hours, the air was continuously blown in during the reaction process, and wind-blown polymerized vegetable oils with different kinematic viscosities were obtained. The results are shown in Table 3.

[0028] table 3

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com