MEMS 5G communication radio frequency antenna and manufacturing process

A technology of radio frequency antenna and manufacturing process, applied in the direction of antenna, antenna parts, antenna support/installation device, etc., can solve the problems of dust contamination, bending damage, etc., and achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

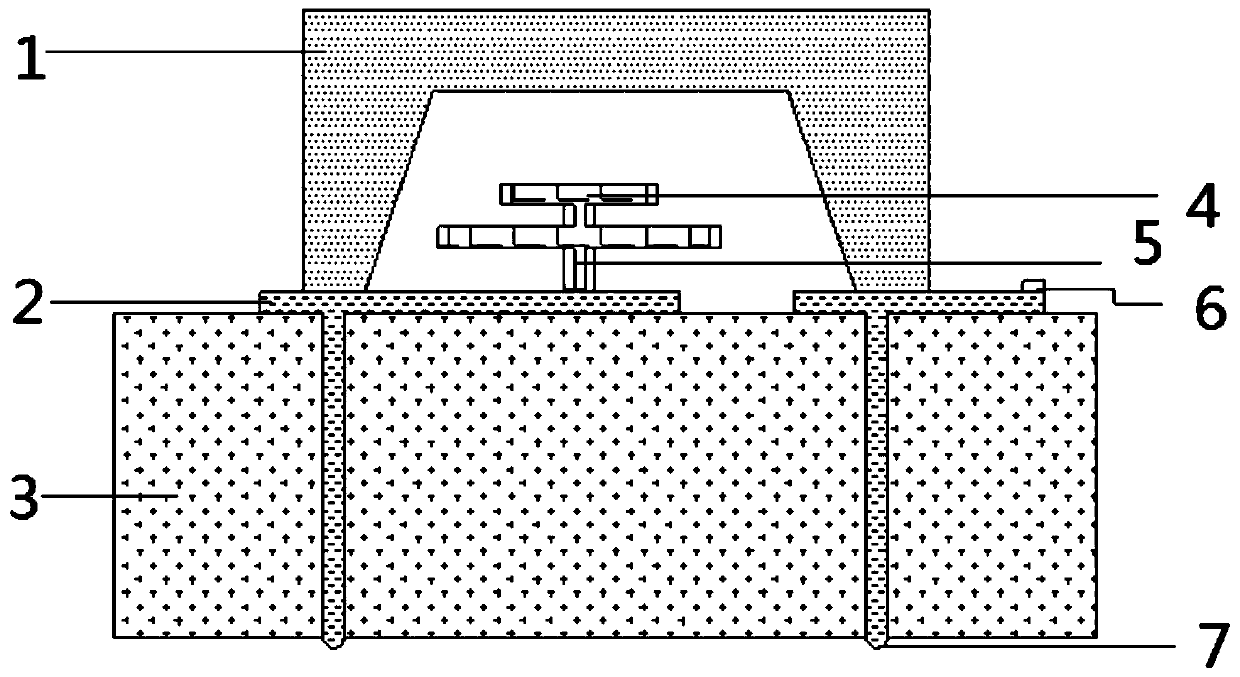

[0022] The present invention provides a MEMS 5G communication radio frequency antenna, which is characterized in that: the MEMS 5G communication radio frequency antenna includes a cap wafer 1, a bonding interface 2, a substrate wafer 3, a micro antenna 4, and a micro antenna anchor point 5. Metal pad 6, metal bump 7, intermediate wafer 8, electrical connection point 9, metal side wall 10, through silicon via connection 11, thin film filter 12, vacuum chamber 13;

[0023] Among them: the cap wafer 1 is used as the protective structure of the micro-antenna, the bonding interface 2 is the interface layer of the cap wafer 1, the substrate wafer 3 and the intermediate wafer 8; the substrate wafer 3 provides the base and external integration for the micro-antenna circuit; the micro-antenna anchor point 5 is the contact part of the micro-antenna 4 and the substrate wafer 3; the metal pad 6 is the metal connection line of the micro-antenna 4, which is used to connect the micro-antenna ...

Embodiment 2

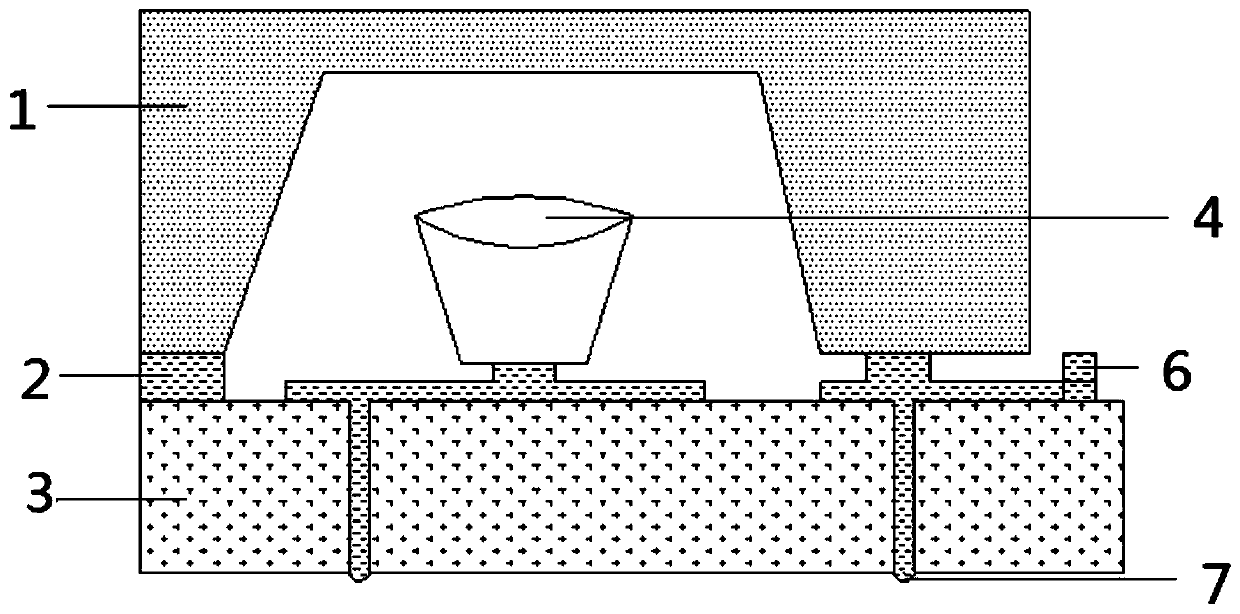

[0032] The present invention provides a MEMS 5G communication radio frequency antenna, which is characterized in that: the MEMS 5G communication radio frequency antenna includes a cap wafer 1, a bonding interface 2, a substrate wafer 3, a micro antenna 4, and a micro antenna anchor point 5. Metal pad 6, metal bump 7, intermediate wafer 8, electrical connection point 9, metal side wall 10, through silicon via connection 11, thin film filter 12, vacuum chamber 13;

[0033]Among them: the cap wafer 1 is used as the protective structure of the micro-antenna, the bonding interface 2 is the interface layer of the cap wafer 1, the substrate wafer 3 and the intermediate wafer 8; the substrate wafer 3 provides the base and external integration for the micro-antenna circuit; the micro-antenna anchor point 5 is the contact part of the micro-antenna 4 and the substrate wafer 3; the metal pad 6 is the metal connection line of the micro-antenna 4, which is used to connect the micro-antenna 4...

Embodiment 3

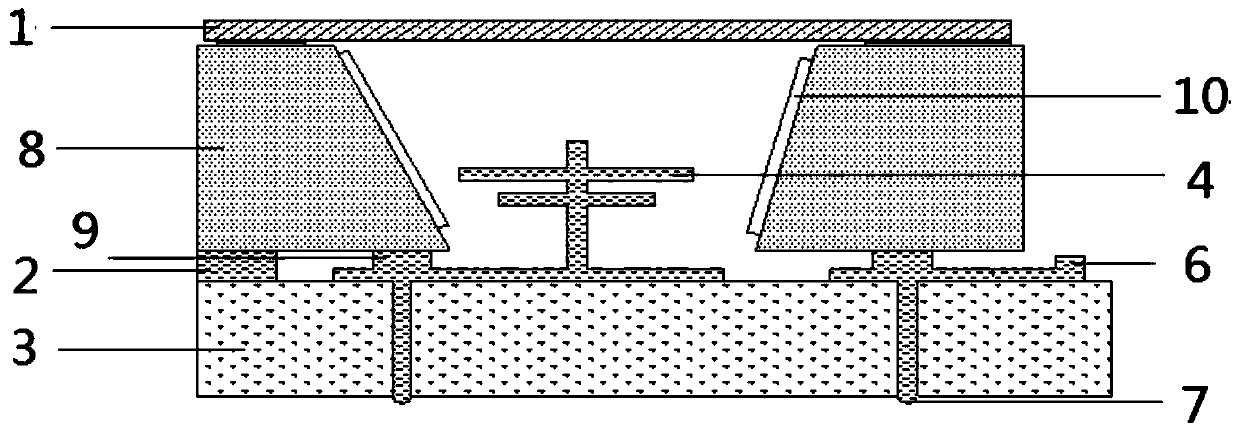

[0041] The present invention provides a MEMS 5G communication radio frequency antenna, which is characterized in that: the MEMS 5G communication radio frequency antenna includes a cap wafer 1, a bonding interface 2, a substrate wafer 3, a micro antenna 4, and a micro antenna anchor point 5. Metal pad 6, metal bump 7, intermediate wafer 8, electrical connection point 9, metal side wall 10, through silicon via connection 11, thin film filter 12, vacuum chamber 13;

[0042] Among them: the cap wafer 1 is used as the protective structure of the micro-antenna, the bonding interface 2 is the interface layer of the cap wafer 1, the substrate wafer 3 and the intermediate wafer 8; the substrate wafer 3 provides the base and external integration for the micro-antenna circuit; the micro-antenna anchor point 5 is the contact part of the micro-antenna 4 and the substrate wafer 3; the metal pad 6 is the metal connection line of the micro-antenna 4, which is used to connect the micro-antenna ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com