Glass ceramic body static inhibitor and preparation method thereof

A technology of glass ceramics and electrostatic suppression, which is applied in the direction of circuits, electrical components, overvoltage arresters with spark gaps, etc. It can solve the problems of large electrical range span, low energy, and high initial trigger voltage of products, and achieve consistent product performance and precision The effect of the control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

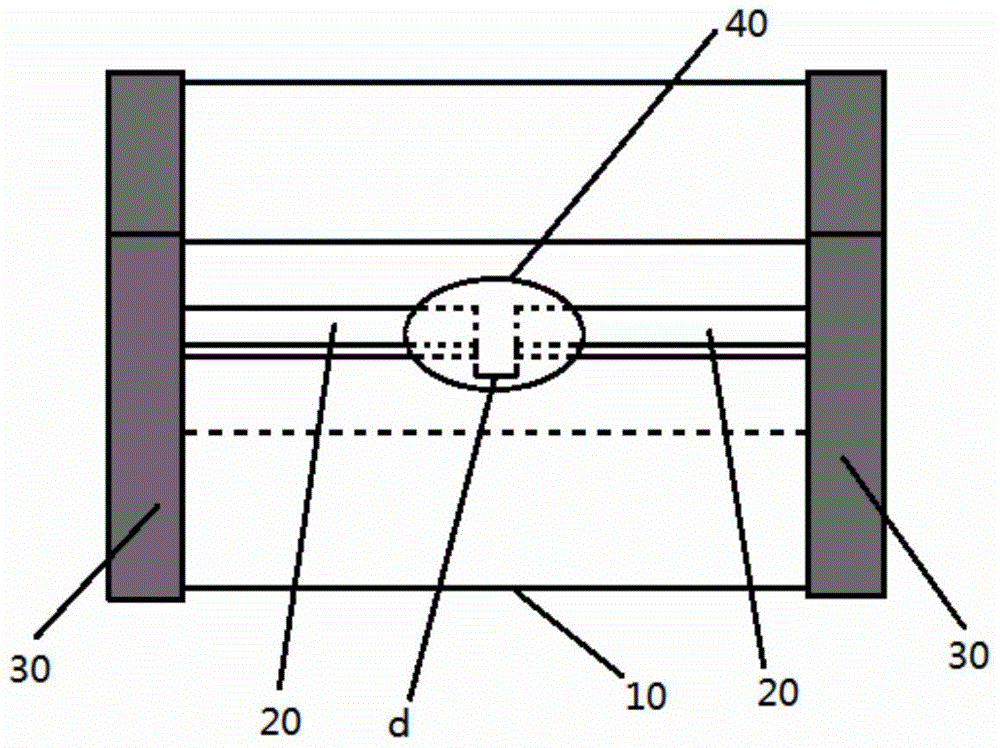

[0033] This embodiment specifically provides a figure 1 The glass-ceramic body static suppressor shown, figure 1 It is a three-dimensional view, and at the same time, the inside of the glass-ceramic substrate is displayed in perspective. Such as figure 1 As shown, the side inner electrodes in this embodiment are arranged opposite to each other in the conductive direction, and the inner ends of the two electrodes are separated by the predetermined distance to form the capacitor structure. When static electricity is generated, the voltage of static electricity is applied to both ends of the capacitive structure, assuming that the breakdown voltage required to break down the gas between two conductors with a distance of d (that is, the inner electrodes on both sides) is V1, then as long as When the peak voltage of the generated static electricity reaches V1, the gas in the capacitor structure in the cavity structure 40 can be broken down to be in a conduction state, and the ele...

Embodiment 2

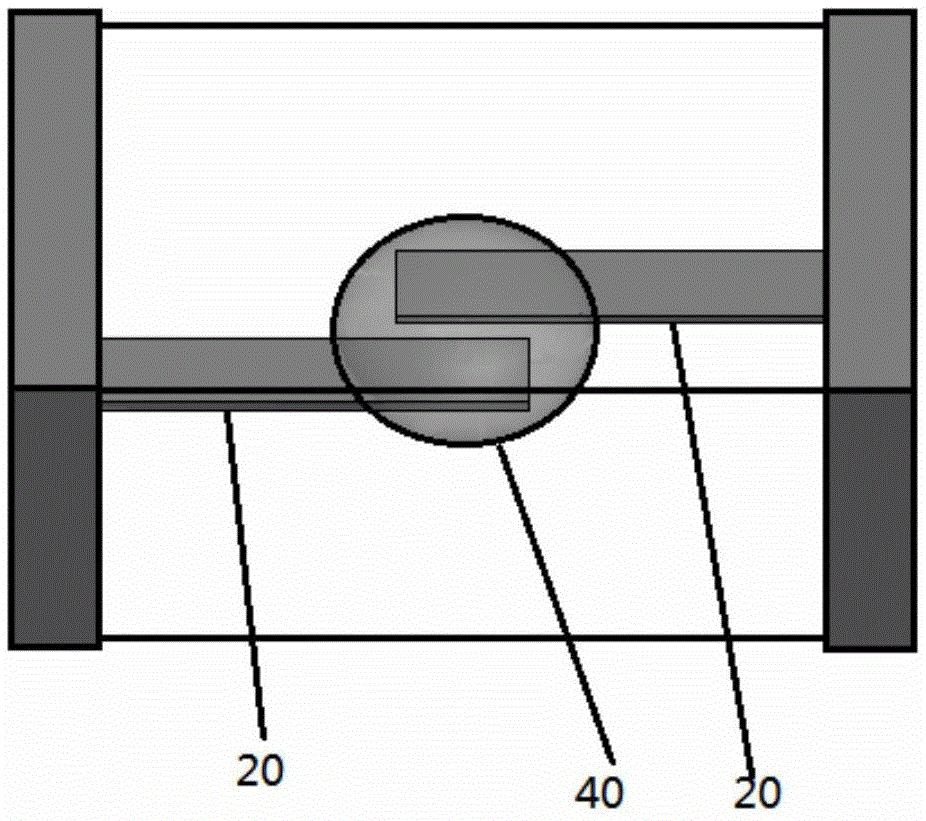

[0035] This specific embodiment provides a kind of figure 2 The glass-ceramic electrostatic suppressor shown differs from Embodiment 1 in that the structure of the side inner electrodes is different. Specific as figure 2 As shown, the two side internal electrodes 20 are arranged in dislocation in the conductive direction, and on the horizontal plane, the two side internal electrodes have overlapping parts in the direction perpendicular to the conductive direction, and the overlapping parts are spaced apart by the predetermined pitch to form the capacitive structure.

Embodiment 3

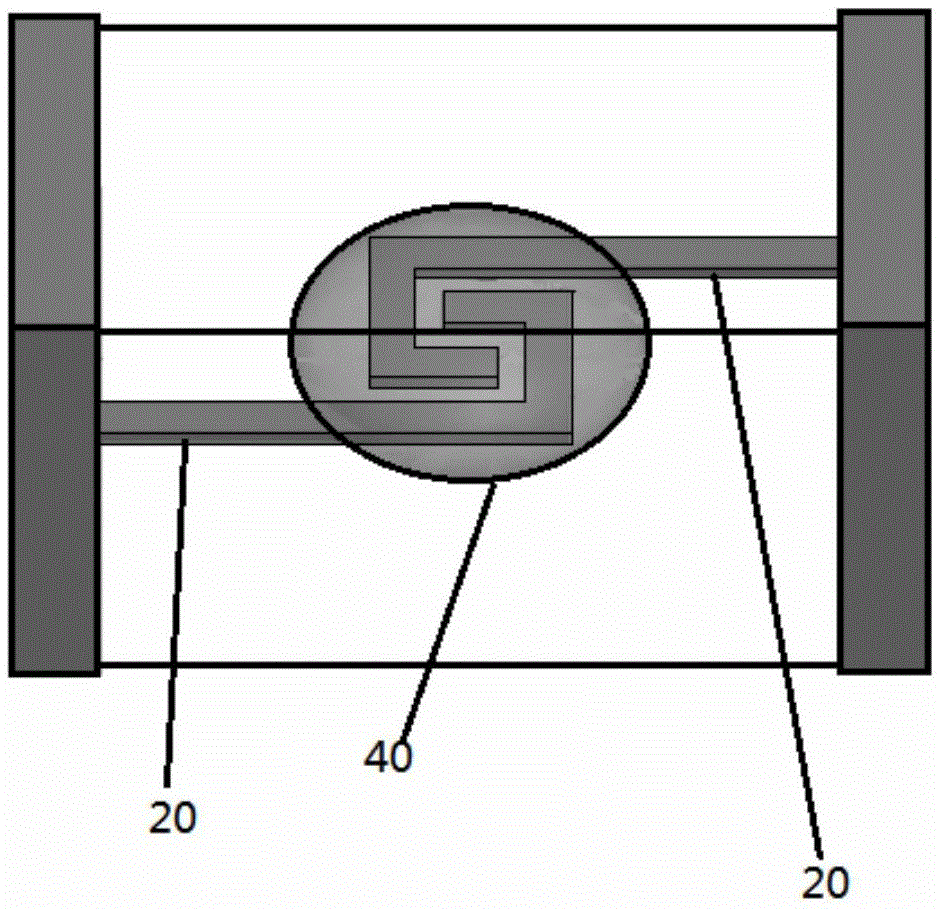

[0037] This specific embodiment provides a kind of image 3 The glass-ceramic electrostatic suppressor shown is different from Embodiment 1 in that: the two side inner electrodes 20 are arranged in a misaligned direction in the conductive direction, and the inner ends of the two form a folded structure with opposite folding directions. The two folded structures with opposite folding directions are misplaced and spiraled on the horizontal plane, so that there is an overlapping portion between the two inner electrodes on the horizontal plane, and the overlapping portions are separated by the predetermined distance to form the The structure of the capacitor.

[0038] Another specific embodiment of the present invention also provides a method for preparing a glass-ceramic static suppressor, which can be used to prepare the glass-ceramic static suppressor provided in the foregoing specific embodiment, specifically comprising the following seven steps:

[0039] S1. Ball milling the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com