Mute constant-rotating-speed control method for brushless motor of high-speed blender

A control method and constant speed technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve problems such as easy vibration, easy heat generation, poor high-speed performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

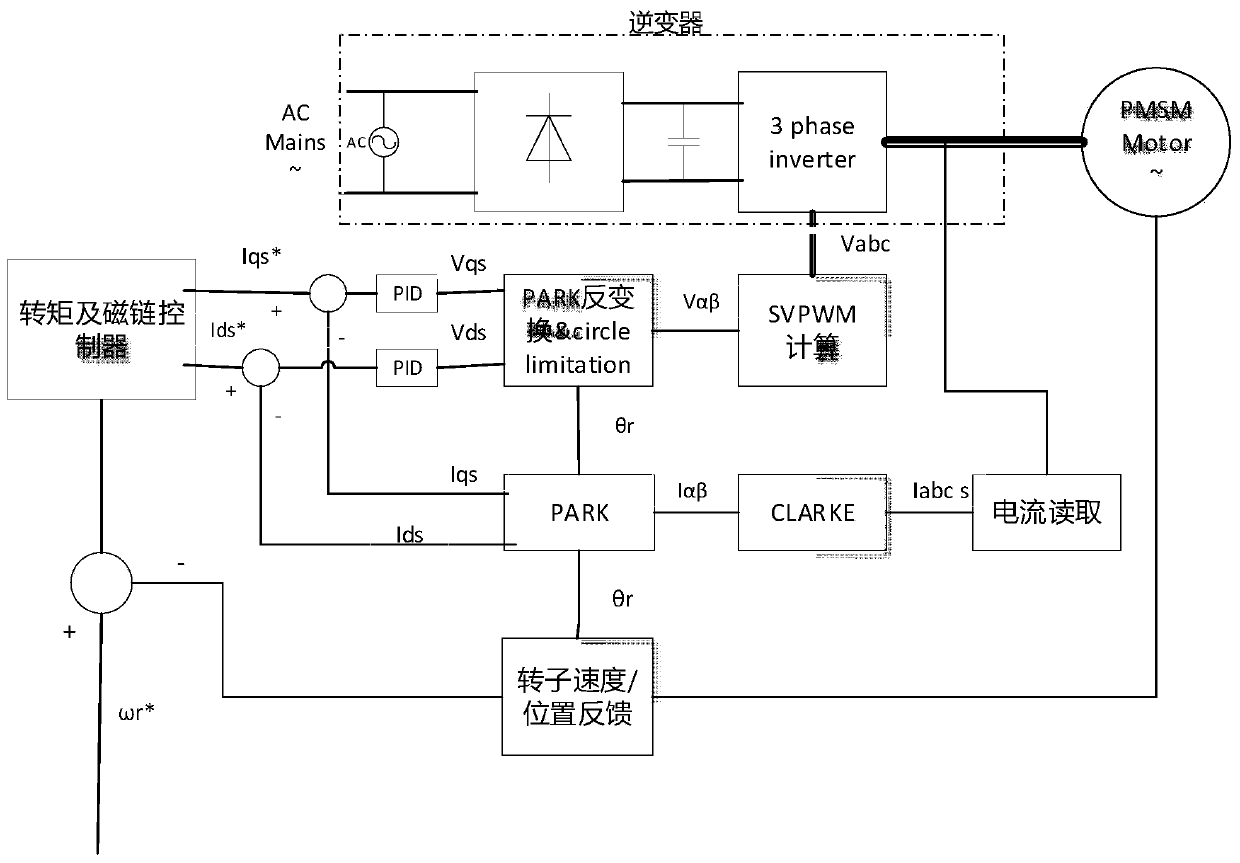

[0014] like figure 1 As shown, one aspect of the present invention provides a silent constant speed control method for a brushless motor of a wall breaker, which is applied to the field of food cooking machines (such as mixers, wall breakers, soybean milk machines or juice extractors) for Reduce the noise when the wall breaking machine products are working, thereby reducing the noise pollution of the wall breaking machine and affecting people's health.

[0015] in, figure 1 The terms in are explained as follows: FOC, rotor field oriented control; 3phase inverter, three-phase converter; PID, proportional integral differential; SVPWM, space vector pulse width modulation; AC Mains, main alternating current; Circlelimitation, pressure limiting circle; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com