A kind of self-grinding drum replacement reactor and multi-energy cascade purification process with anti-return solution

A reactor and self-grinding technology, applied in the direction of photography process, photography auxiliary process, process efficiency improvement, etc., can solve the problems of many processing equipment, long process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

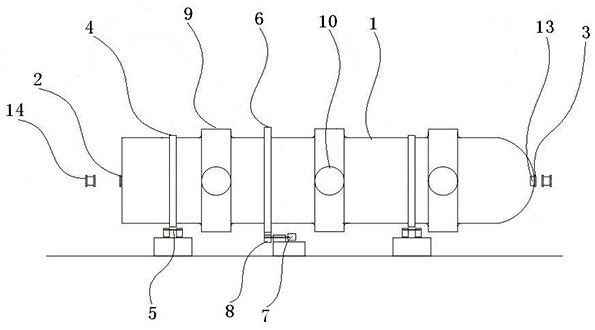

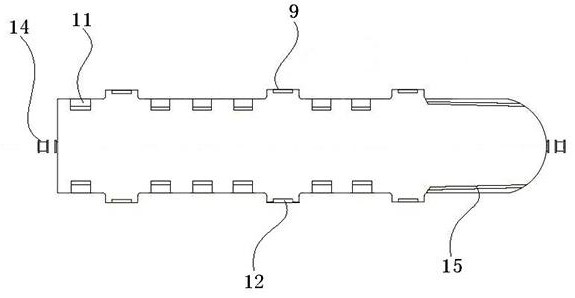

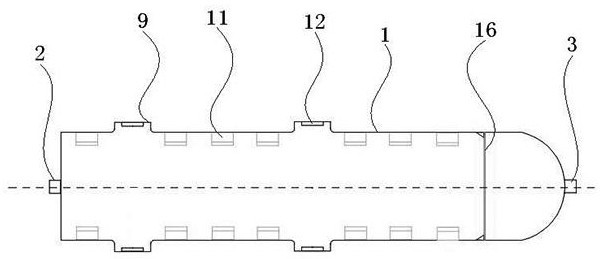

[0038] Such as Figure 1-6 The self-grinding drum displacement reactor shown includes a displacement reactor 1, a liquid inlet 2, a liquid outlet 3, a supporting ring 4, a supporting wheel 5, a ring gear 6, a driving device 7, a driving ring gear 8, Enhanced self-grinding tank 9, feeding hole 10, lifting plate 11, and powder lifting plate 12, characterized in that: the displacement reactor 1 is designed as a drum, and one end of the displacement reactor 1 is provided with a liquid inlet 2, and the displacement reactor 1 The other end of the displacement reactor 1 is provided with a liquid outlet 3, and the two ends of the outer surface of the cylinder of the displacement reactor 1 are respectively provided with support rings 4, and the two support rings 4 are placed on two sets of supporting wheels 5 oppositely arranged at the bottom of the displacement reactor 1. The outer surface of the cylinder of the displacement reactor 1 between the supporting rings 4 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com