Etamsylate injection and preparation method thereof

A technology of phensulfame and injection, which is applied in the field of phensulfame injection and its preparation, can solve problems such as unstable pH, doubts about the reputation of manufacturers, and returns from users, and achieve the effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

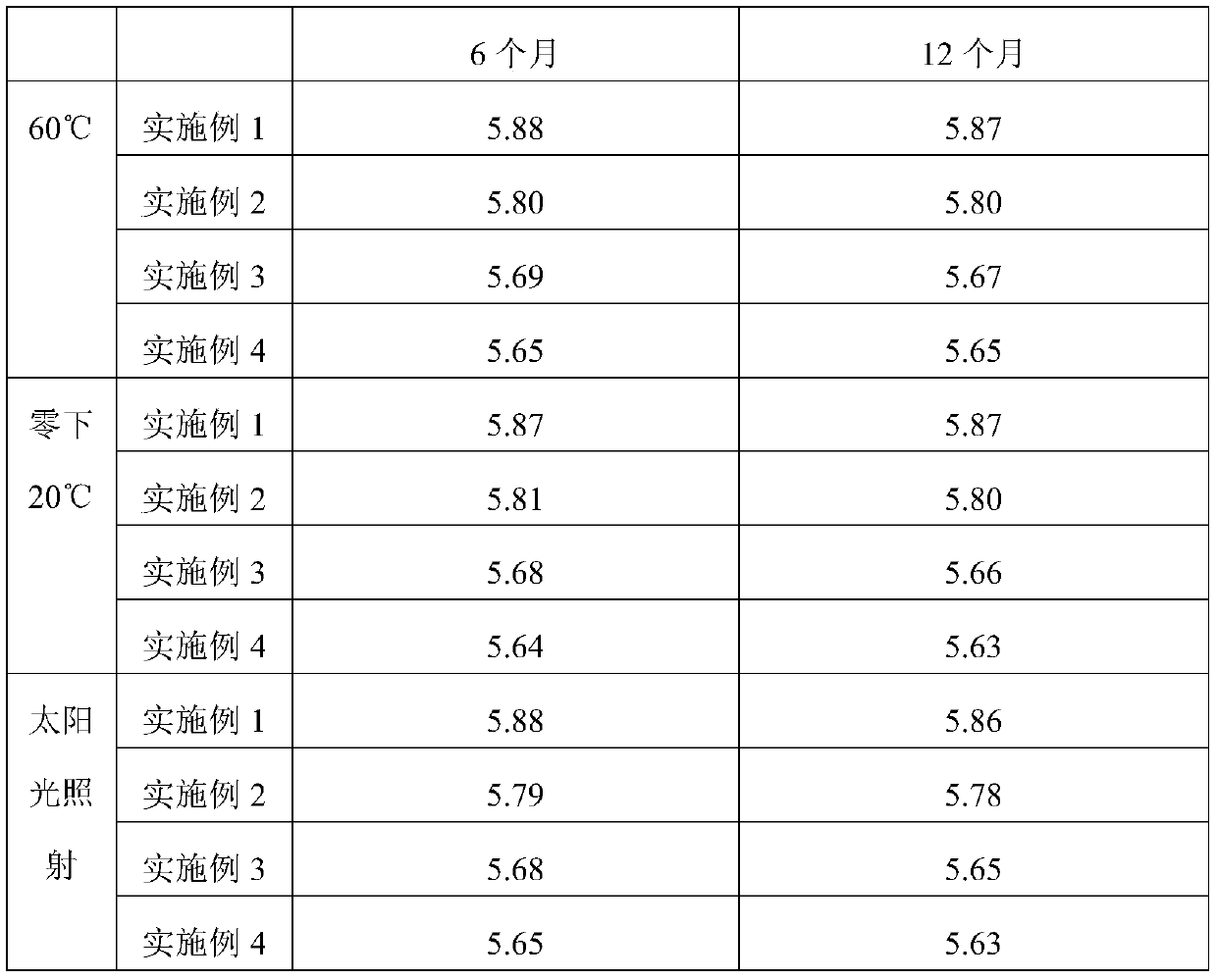

Examples

Embodiment 1

[0015] A kind of phensulfame injection, comprising following raw materials, phensulfame 500g, disodium edetate 2g, sodium metabisulfite 1g, sodium chloride 15g, water for injection 2000ml, mannitol 0.1g, potassium chloride 1g, Calcium chloride 2g.

[0016] A kind of preparation method of ethylamine injection, it is characterized in that, preparation steps are as follows: (1) configure ethylamine, disodium edetate, sodium pyrosulfite, the saturated solution of sodium chloride respectively at 25 ℃ for subsequent use ; Dissolve mannitol, potassium chloride and calcium chloride at 25°C in 10ml water for injection to obtain a trace element solution for subsequent use; Mix the saturated solution and the trace element solution at 25°C to obtain the raw material concentrated liquid; (3) put the raw material concentrated liquid in the concentrated preparation tank, add activated carbon to the concentrated preparation tank, absorb at 38°C for 25 minutes, and filter until the concentrate...

Embodiment 2

[0021] A kind of phensulfame injection, comprising following raw materials, phensulfame 480g, edetate disodium 1g, sodium metabisulfite 2g, sodium chloride 14g, water for injection 2000ml, mannitol 0.2g, potassium chloride 0.8g , calcium chloride 1.5g.

[0022] A kind of preparation method of ethylamine injection, it is characterized in that, preparation steps are as follows: (1) configure ethylamine, disodium edetate, sodium pyrosulfite, the saturated solution of sodium chloride respectively at 25 ℃ for subsequent use ; Dissolve mannitol, potassium chloride and calcium chloride at 25°C in 10ml water for injection to obtain a trace element solution for subsequent use; Mix the saturated solution and the trace element solution at 25°C to obtain the raw material concentrated liquid; (3) put the raw material concentrated liquid in the concentrated preparation tank, add activated carbon to the concentrated preparation tank, absorb at 38°C for 25 minutes, and filter until the concen...

Embodiment 3

[0027] A kind of phensulfame injection, comprising following raw materials, phensulfame 450g, edetate disodium 0.5g, sodium metabisulfite 0.5g, sodium chloride 15g, water for injection 2000ml, mannitol 1g, potassium chloride 1.5 g, calcium chloride 1g.

[0028] A kind of preparation method of ethylamine injection, it is characterized in that, preparation steps are as follows: (1) configure ethylamine, disodium edetate, sodium pyrosulfite, the saturated solution of sodium chloride respectively at 25 ℃ for subsequent use ; Dissolve mannitol, potassium chloride and calcium chloride at 25°C in 10ml water for injection to obtain a trace element solution for subsequent use; Mix the saturated solution and the trace element solution at 25°C to obtain the raw material concentrated liquid; (3) put the raw material concentrated liquid in the concentrated preparation tank, add activated carbon to the concentrated preparation tank, absorb at 38°C for 25 minutes, and filter until the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com