A kind of variable rigidity composite vehicle frame preparation method and the vehicle frame prepared therewith

A stiffness and frame technology, applied to vehicle parts, other household appliances, household appliances, etc., can solve problems such as vibration and noise, abnormal deformation of the frame, body roll, etc., and achieve the effect of improving safety and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

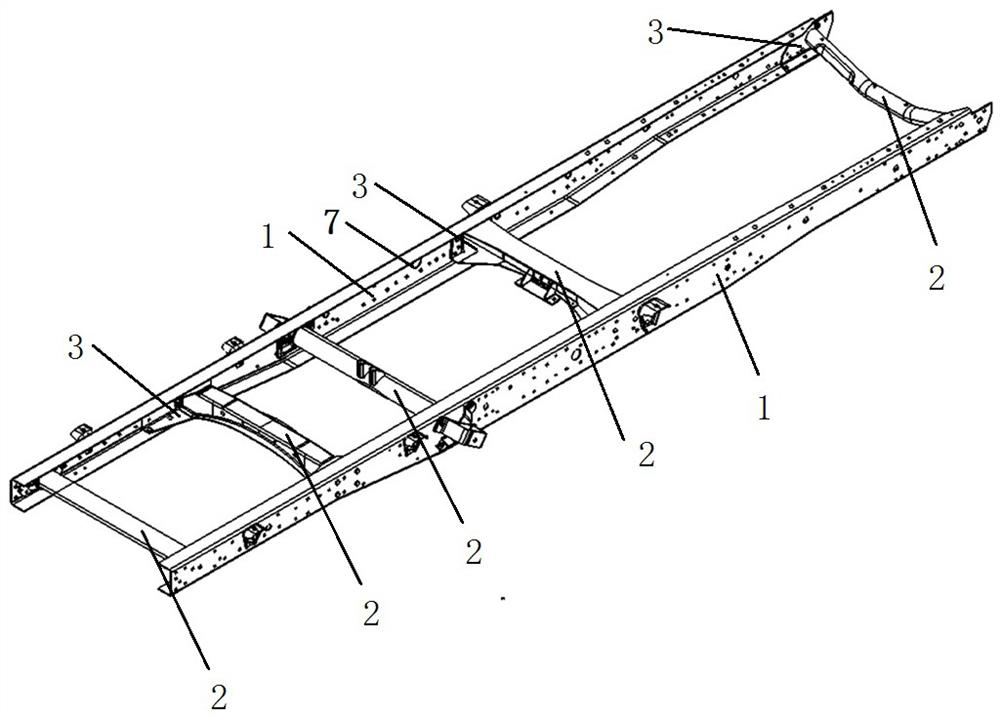

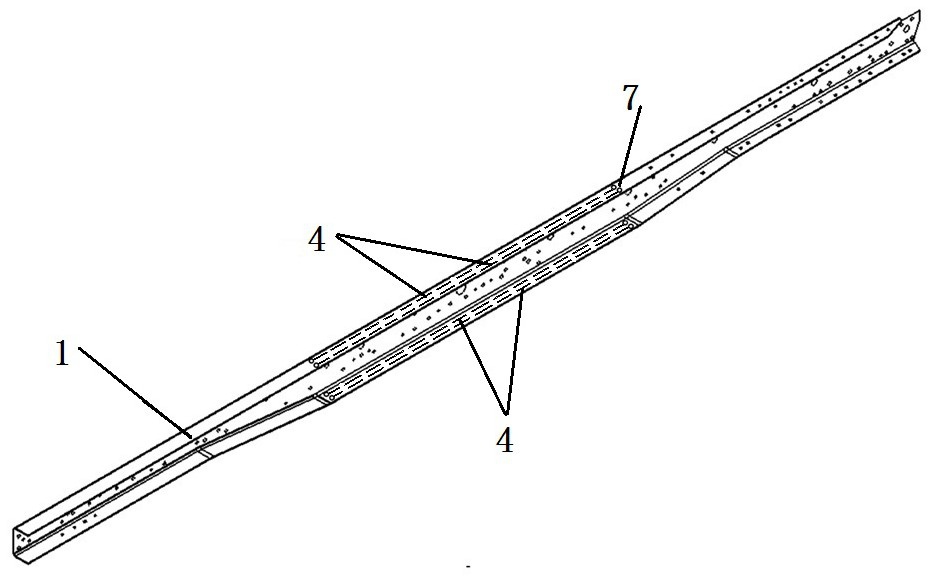

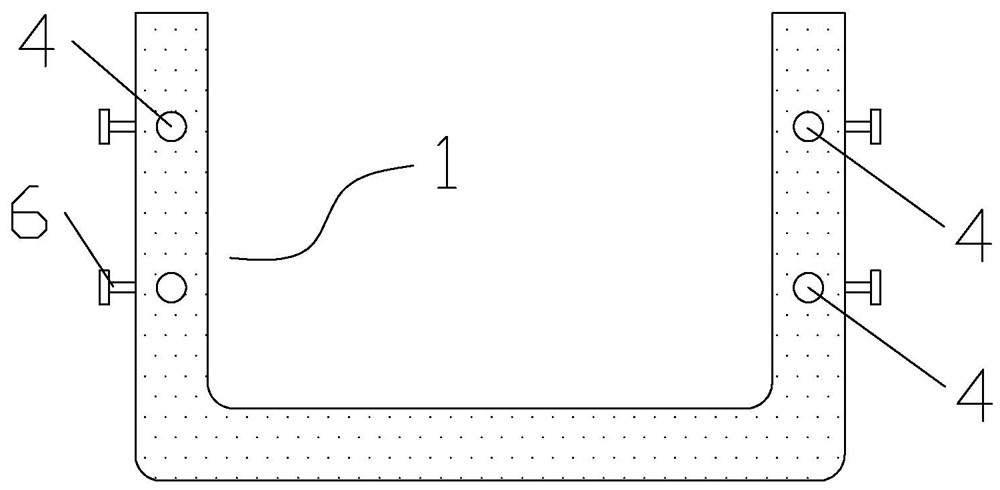

[0034] like figure 1 , 2 , As shown in 3 and 4, a composite vehicle frame with variable stiffness includes two longitudinal beams 1 arranged in parallel, a number of beams 2 are connected between the longitudinal beams 1, and a The connecting liner 3 is used to completely fix the longitudinal beam 1 and the cross beam 2; the cross section of the longitudinal beam 1 is a U-shaped structure, and the two wings of the longitudinal beam 1 are respectively implanted with stiffness drivers 4, which contain The three-dimensional braid of shape memory alloy wire, the two ends of the stiffness driver 4 are connected to the vehicle power supply; the frame of this design has the function of active stiffness control, which can realize the active control of the key stiffness characteristics of the frame according to different load conditions, not only Improve the level of light weight and comfort of the vehicle, and greatly improve the safety of the vehicle;

[0035] The stiffness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com