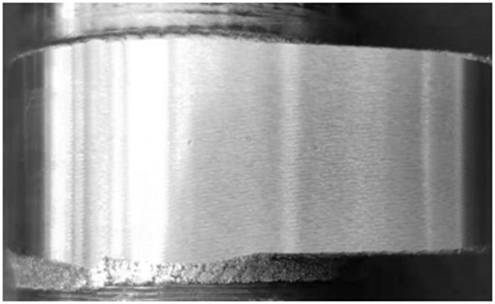

A kind of laser cladding powder for 12crni3 camshaft remanufacturing and preparation method thereof

A laser cladding and remanufacturing technology, used in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of high cost, complex process, tiny pores in the camshaft cladding layer, etc., to achieve good performance and simplification. Remanufacturing process, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

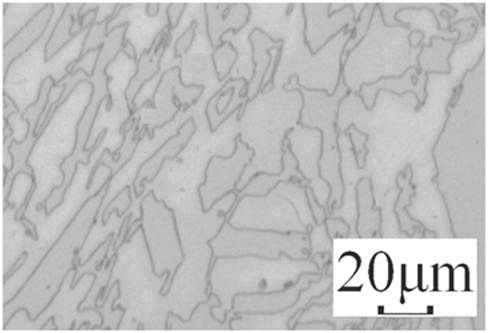

Embodiment 1

[0022] Example 1: The mass fraction of each element in the 12CrNi3 camshaft remanufactured laser cladding powder provided in this example is: C: 0.35%, Cr: 4.0%; Ni: 7.3%; Al: 4.6%; Mn: 3.4% ; Mo: 0.7%; Si: 0.16%; Nb: 0.3%; Rare earth: 0.015%; S: 0.015%; P: 0.020%; Among them, the rare earth is mixed rare earth, the product brand is 194020A, and the composition should comply with the provisions of "GB / T 4153-2008 Mixed Rare Earth Metals".

[0023] The above-mentioned raw materials, except for Al, are thoroughly mixed and then smelted and atomized. Alloy powder with a particle size range of 60 μm-180 μm after atomization is taken and mechanically mixed with Al powder.

Embodiment 2

[0024] Example 2: The mass fraction of each element in the 12CrNi3 camshaft remanufactured laser cladding powder provided in this example is: C: 0.40%, Cr: 3.8%; Ni: 8.2%; Al: 4.3%; Mn: 3.0% ; Mo: 0.5%; Si: 0.20%; Nb: 0.35%; Rare earth: 0.017%; S: 0.015%; P: 0.020%; Among them, the rare earth is mixed rare earth, the product brand is 194020A, and the composition should comply with the provisions of "GB / T 4153-2008 Mixed Rare Earth Metals".

[0025] The above-mentioned raw materials, except for Al, are thoroughly mixed and then smelted and atomized. Alloy powder with a particle size range of 60 μm-180 μm after atomization is taken and mechanically mixed with Al powder.

Embodiment 3

[0026]Example 3: The mass fraction of each element in the 12CrNi3 camshaft remanufactured laser cladding powder provided in this example is: C: 0.45%, Cr: 4.2%; Ni: 8.5%; Al: 4.8%; Mn: 3.6% ; Mo: 0.8%; Si: 0.25%; Nb: 0.4%; Rare earth: 0.014%; S: 0.015%; P: 0.020%; Among them, the rare earth is mixed rare earth, the product brand is 194020A, and the composition should comply with the provisions of "GB / T 4153-2008 Mixed Rare Earth Metals".

[0027] The above-mentioned raw materials, except for Al, are thoroughly mixed and then smelted and atomized. Alloy powder with a particle size range of 60 μm-180 μm after atomization is taken and mechanically mixed with Al powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com