High-performance transparent conductive film and preparation method and application thereof

A technology of transparent conductive film and conductive film, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., and can solve complex processes, decreased transmittance, and high toxicity etc. to achieve the effect of high repeatability, low roughness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Clean the substrate: Arrange the 1cm*1cm non-alkali glass substrate on the film rack, put it into a large beaker, and ultrasonically clean it with deionized water and isopropanol for 15 minutes respectively.

[0031] (2) Substrate drying: put the cleaned glass substrate into an oven, and dry it at 75-85°C.

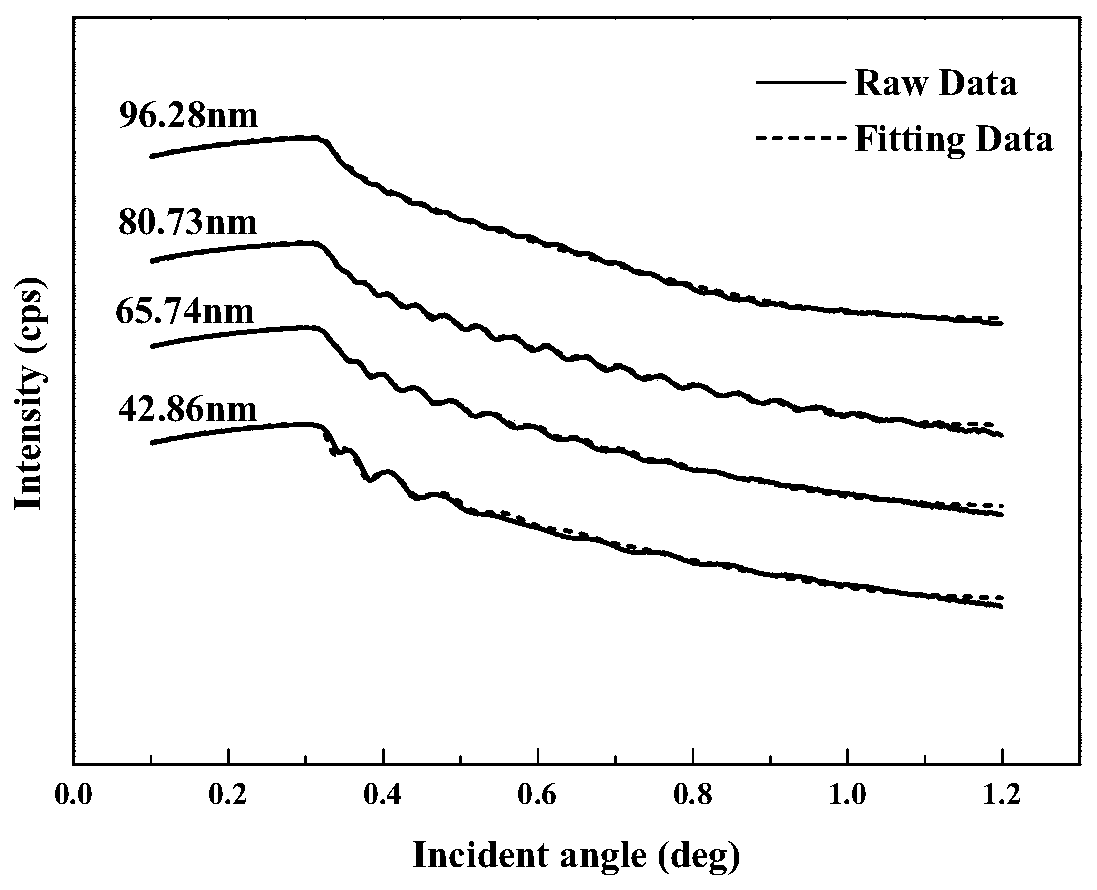

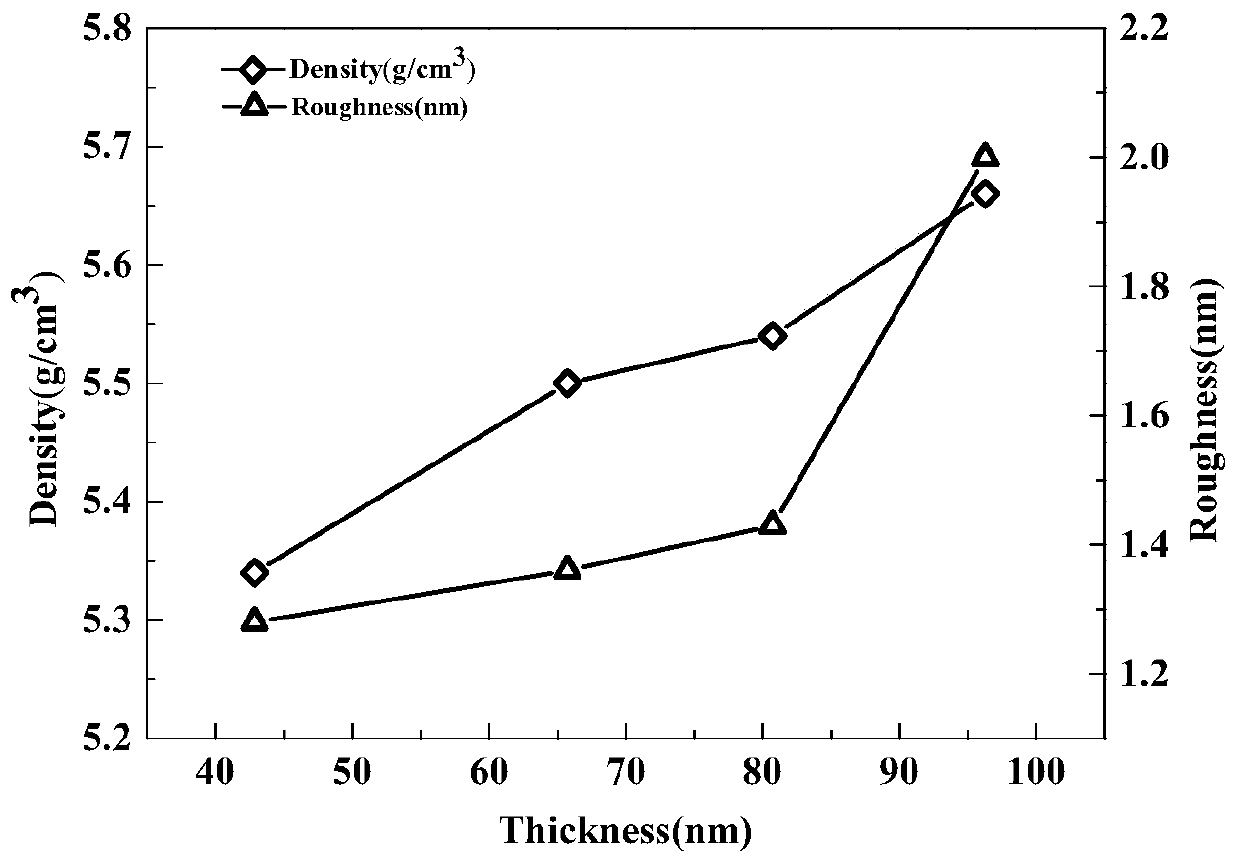

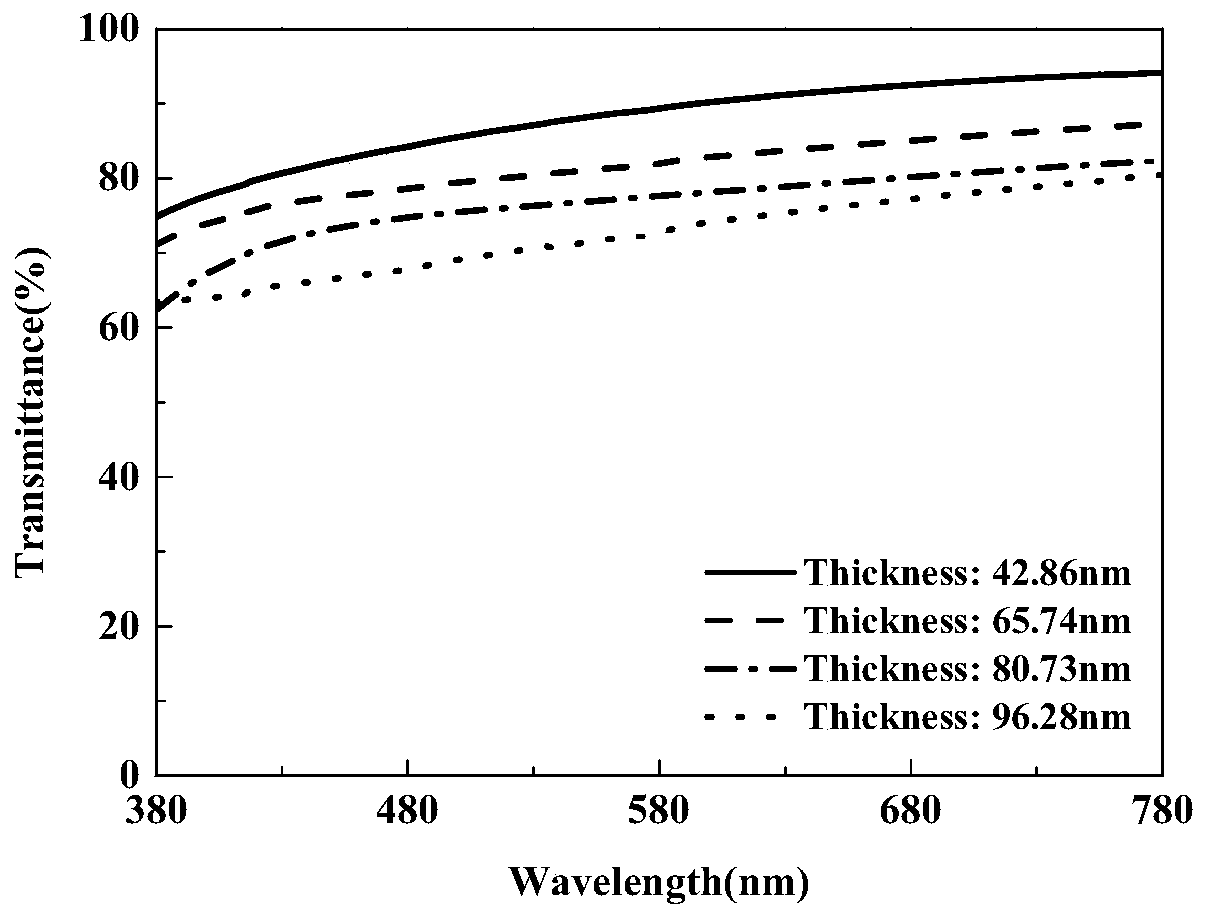

[0032] (3) Deposit GZO conductive thin film using pulsed laser deposition system at room temperature, the material is GZO (2wt%Ga2O3, 98wt%ZnO) target, set the distance from the target to the substrate as 7.5cm, pulse energy 450mJ, frequency 5Hz, oxygen content 0Pa , the number of deposition pulses is 1500, and a high-performance transparent conductive film is obtained.

Embodiment 2

[0034] (1) Clean the substrate: Arrange the 1cm*1cm non-alkali glass substrate on the film rack, put it into a large beaker, and ultrasonically clean it with deionized water and isopropanol for 15 minutes respectively.

[0035] (2) Substrate drying: put the cleaned glass substrate into an oven, and dry it at 75-85°C.

[0036] (3) Deposit GZO conductive thin film using pulsed laser deposition system at room temperature, the material is GZO (2wt%Ga2O3, 98wt%ZnO) target, set the distance from the target to the substrate as 7.5cm, pulse energy 450mJ, frequency 5Hz, oxygen content 0Pa , the number of deposition pulses is 2250, and a high-performance transparent conductive film is obtained.

Embodiment 3

[0038] (1) Clean the substrate: Arrange the 1cm*1cm non-alkali glass substrate on the film rack, put it into a large beaker, and ultrasonically clean it with deionized water and isopropanol for 15 minutes respectively.

[0039] (2) Substrate drying: put the cleaned glass substrate into an oven, and dry it at 75-85°C.

[0040] (3) Deposit GZO conductive thin film using pulsed laser deposition system at room temperature, the material is GZO (2wt%Ga2O3, 98wt%ZnO) target, set the distance from the target to the substrate as 7.5cm, pulse energy 450mJ, frequency 5Hz, oxygen content 0Pa , the number of deposition pulses is 3000, and a high-performance transparent conductive film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com