Low-capacitance high-power transient voltage suppressor and manufacturing method thereof

A technology of transient voltage suppression and manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, circuits, etc., can solve the problems of increased parasitic capacitance, inability to meet high-speed signal port transmission, data loss, etc., and achieve high reliability. performance, avoiding the risk of potential failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

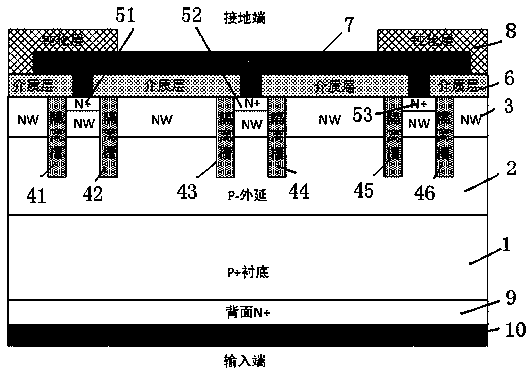

[0070] A low capacitance high power transient voltage suppressor such as figure 1 with 8 As shown, the present invention grows P- epitaxial layer 2 on the front of P+ substrate 1 by P+ substrate; N lightly doped NW region 3 is grown on the surface of P- epitaxial layer, and NW region 3 is formed by isolation grooves one, two, three, Four, five, and six 41, 42, 43, 44, 45, and 46 constitute three pairs of ablation grooves, the groove depth is greater than the thickness of the NW layer, and the NW in each pair of isolation grooves is doped with N-type heavy doping to form an N+ region 1, 2, 3 51, 52, 53, there is a dielectric layer 6 on the upper surface of the silicon wafer composed of NW, N+ and isolation grooves, and the front metal layer 7 is connected to the upper surface of the N+ region 1, 2, 3 51, 52, 53 Metal leads, connected to the front metal layer 7, with a passivation layer 8 on the upper surface, forming a front metal window, used for the grounding terminal in the...

Embodiment 2

[0096] In this embodiment, a low-capacitance high-power transient voltage suppressor, such as Figure 9As shown, the others are the same as in Embodiment 1, except that the photolithography plate is omitted before the front N+ layer 5 with the same or similar chip area is injected into the front side, and the entire surface is directly implanted on the upper surface of the silicon wafer, so that the performance is not affected. Next, the manufacturing cost is reduced.

[0097] On the back of the substrate, a large-area N+ / P+ junction reverse-biased diode T1 with the same area as the entire chip is formed by doping, and three small-junction area P+ substrate / P- epitaxy / NW / A diode series structure composed of N+.

Embodiment 3

[0099] In this embodiment, a low-capacitance high-power transient voltage suppressor, such as Figure 10 As shown, the others are the same as in Embodiment 1, except that shallow grooves 1 and 2 111 and 112 on the back are added, and the depth of the grooves is greater than that of the N+ junction on the back.

[0100] On the back of the P+ substrate, the back N+ layer is formed by doping to form a large-area N+ / P+ junction reverse-biased diode T1 that is similar to the entire chip area, and three small junction areas that are limited in each group of isolation grooves P+ substrate / P -Diode series structure composed of epitaxial / NW / N+.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com