Intelligent control dragging device of combined permanent magnet variable-frequency synchronous oil pumping unit

A technology of intelligent control and dragging device, which is applied in electromechanical devices, synchronous motors with stationary armatures and rotating magnets, electrical program control, etc., can solve the lack of real-time remote transmission of control cabinet detection data, and the disconnection between motors and intelligent digitalization , Inability to effectively use electrical parameter control and other issues to achieve the effects of reducing stator copper consumption, small motor current, and low slippage during operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

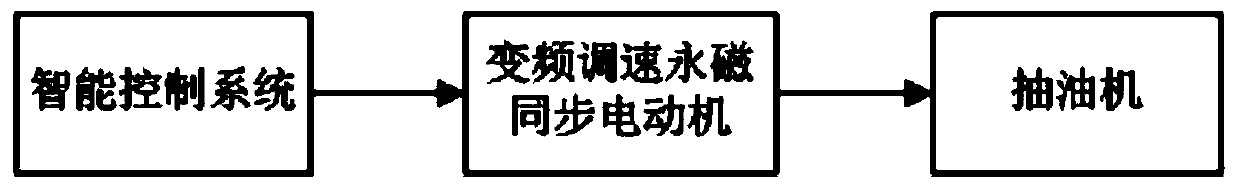

[0042] Such as figure 1 As shown, the variable frequency speed regulating permanent magnet synchronous motor and the pumping unit are connected through a belt, and the intelligent control system remotely controls the frequency conversion speed regulating permanent magnet synchronous motor and transmits the detection data of the pumping unit in real time through the wireless network;

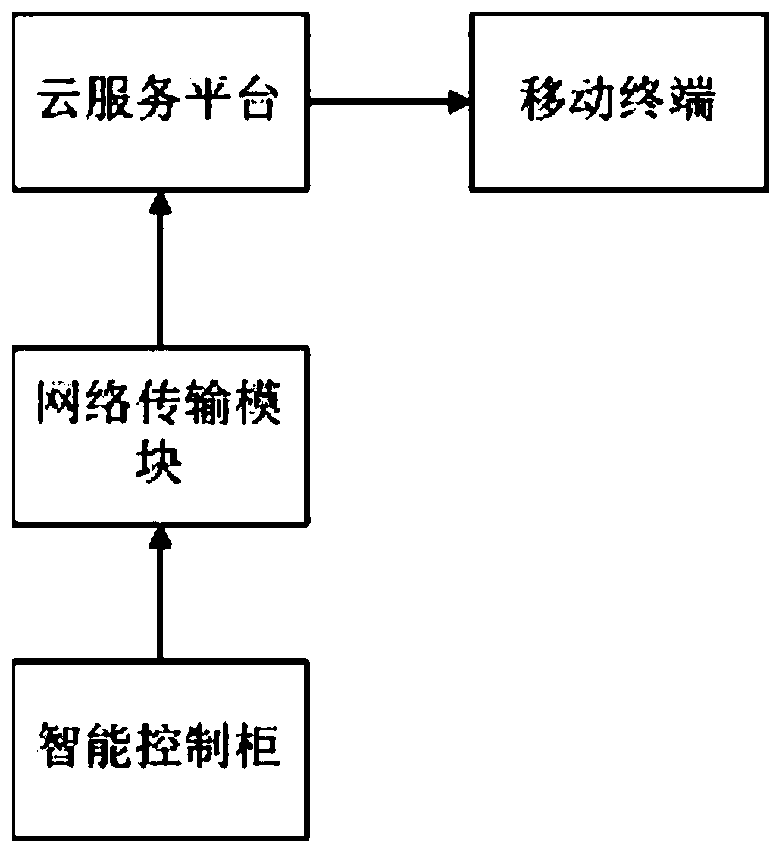

[0043] Such as figure 2 As shown, the intelligent control system includes a network transmission module, a cloud service platform, a mobile terminal and an intelligent control cabinet. The intelligent control cabinet is connected to the cloud service platform through the network transmission module, and the output terminal of the cloud service platform is connected to the input terminal of the mobile terminal.

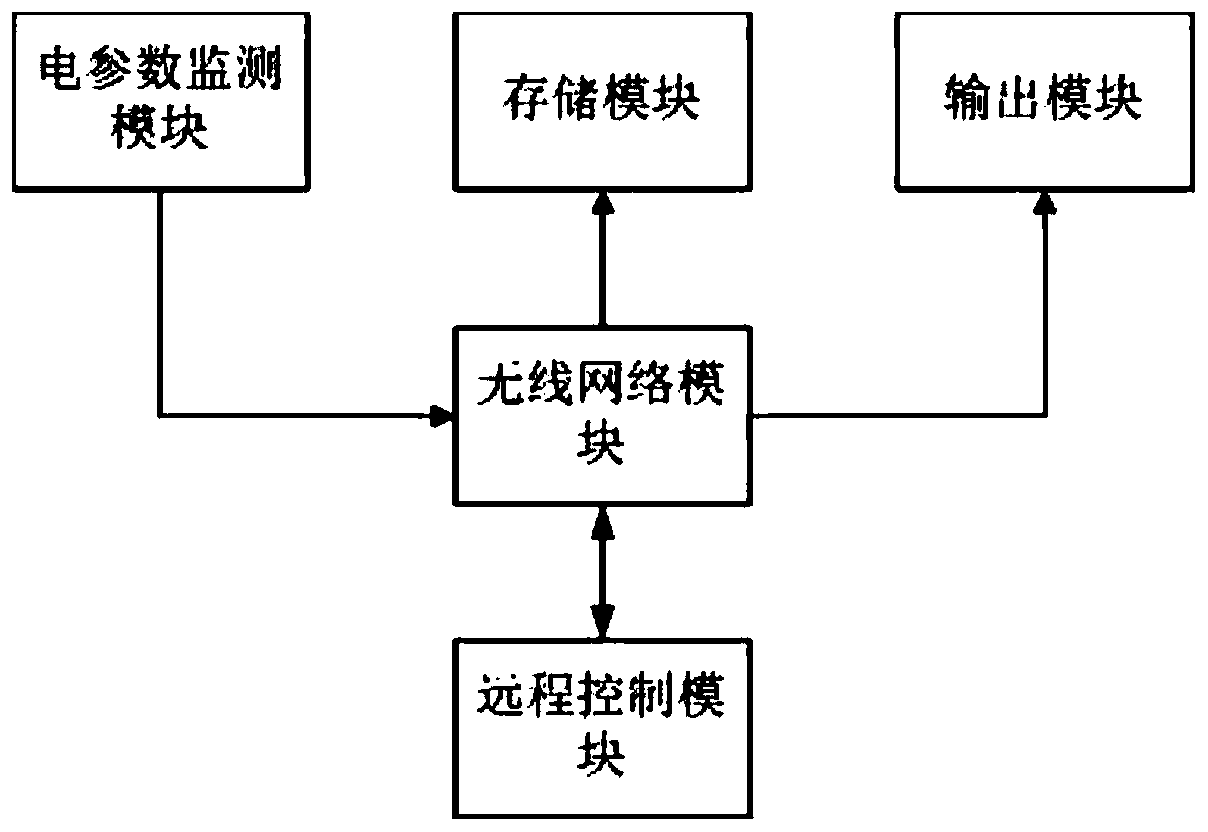

[0044] Such as image 3 As shown, the intelligent control cabinet includes an electrical parameter monitoring module, a remote control module, a storage module, an output module and a w...

Embodiment 2

[0049] A manufacturing method of a combined permanent magnet variable frequency synchronous pumping unit intelligent control drive motor driving device:

[0050] 1. Special technology for "one-knife-through" processing of the casing:

[0051] The casing is the core component of the motor support system. The most basic requirement for the casing is to have sufficient mechanical strength, dimensional accuracy and coaxiality accuracy. The mechanical strength is guaranteed by the material, structure and thickness of the casing, and the dimensional accuracy is also guaranteed. It is easy to guarantee, but the coaxiality accuracy is very important. If the coaxiality accuracy cannot be guaranteed, it will cause uneven air gap of the motor and affect the performance of the motor, and it will cause the stator and rotor of the motor to rub against each other, so that the motor cannot work normally and will be lost in advance. motor function.

[0052] In the prior art, the current gener...

Embodiment 3

[0075] In this embodiment, the driving part is composed of a permanent magnet variable frequency synchronous motor and a pulley, and the permanent magnet synchronous motor is mainly composed of a stator and a rotor. The rotor is mainly composed of rotor core, magnetic steel, and rotating shaft. The rotor core is composed of rotor punches and magnetic steel. The magnetic steel in the rotor core is arranged in a radial and tangential hybrid arrangement. After combination, it forms a squirrel-cage-free, magnetic Steel built-in hybrid rotor with no reactive power consumption. The stator adopts conventional stator core and stator winding. These two parts constitute the motor drive part capable of variable frequency rotation, the structure is shown in Figure 4 , Working principle: The rotor of the motor is equipped with magnetic steel. Due to the existence of the rotor magnetic steel, an air gap magnetic flux is formed inside the motor, and a three-phase stator current is generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com