System and method for eliminating colored smoke plume in wet desulphurization flue gas

A wet desulfurization and wet flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as large consumption of cold or heat sources, high operating costs, and poor environmental adaptability to white smoke elimination. , to achieve the effect of eliminating blue smoke and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

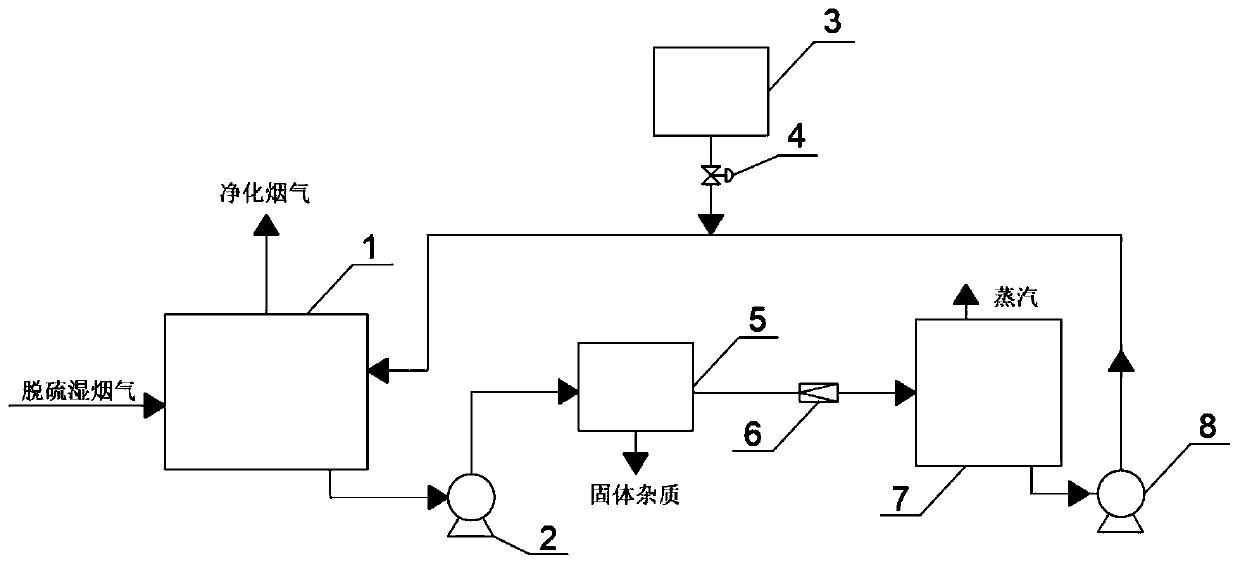

[0050]This embodiment provides a system for eliminating colored plumes in wet desulfurization flue gas, please refer to figure 1 , which includes a supergravity dehumidification absorber 1 so that the desulfurized wet flue gas and absorbent are mixed in the supergravity dehumidification absorber 1 to remove water vapor and SO 3 .

[0051] For reference, the water content in the desulfurized wet flue gas can be reduced by the water vapor partial pressure on the surface of the absorbent and the vapor pressure difference in the desulfurized wet flue gas, for example, about 60-70% of the water in the desulfurized wet flue gas can be removed steam.

[0052] For reference, the shear mixing of the desulfurized wet flue gas and the absorbent through the supergravity bed in the supergravity dehumidification absorber 1 affects the SO in the desulfurized wet flue gas. 3 Carry out chemical absorption to remove, to achieve the purpose of completely eliminating blue smoke.

[0053] The a...

Embodiment 2

[0076] This embodiment provides a method for eliminating colored plume in wet desulfurization flue gas, comprising the following steps: using the system for eliminating colored plume in wet desulfurization flue gas in Example 1, combining desulfurization wet flue gas with absorbent Mixed removal of water vapor and SO in supergravity dehumidification absorber 1 3 .

[0077] Water vapor and SO in desulfurization wet flue gas 3 The removed absorbent is introduced into the filter 5 through the first power pump 2 to remove the solid impurities in the absorbent, and then enters the decompression valve 6 to the flash evaporator 7 for flash separation, and the separated absorbent It is introduced into the supergravity dehumidification absorber 1 through the second power pump 8 for recycling.

[0078] According to the water vapor and SO in the desulfurized wet flue gas 3 The dehumidification effect of the supergravity dehumidification absorber 1 is supplemented with new absorbent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com